JCB is celebrating 50 years of wheeled loading shovel manufacture.

The company originally entered the wheeled loader market with the acquisition of UK-based Chaseside Engineering, taking on its seven-strong line-up of machines.

Relocation of production lines from Chaseside’s plant in Lancashire (England) took several months. 1969 marked the start of the first full year of shovel manufacturing at JCB’s growing Rocester factory in Staffordshire.

In that first year, the wheeled loader division built 298 machines – catering primarily for “domestic customer demand”.

JCB now produces wheeled loaders in their thousands on production lines around the world, including the UK, India, Brazil and China. This year also marks the 20th anniversary of JCB opening a multi-million pound factory in Cheadle, Staffordshire, dedicated to the production of wheeled loaders.

History of JCB loaders

The first JCB-designed loaders arrived way back in 1971, with the launch of the 413 (pictured below) and 418 models – replacing the existing Chaseside machines.

These had a cab mounted on the front section of the articulating chassis, supposedly to provide the operator with a better view. They were also notable for having an oscillating centre pivot.

A year later, in 1972, JCB launched a tracked loading shovel – namely the 110 (pictured below).

In 1973, the 423 and 428 (pictured below) were launched. These machines brought JCB into the realm of heavier-duty shovels.

In 1975, following on from the earlier 110, JCB unleashed two new crawler loaders – namely the 112 and 114.

By the early 1980s, JCB’s loader division had grown further, with the introduction of the 428 landfill compactor. The early 1980s also heralded the arrival of the 410, 420 and 430 – notable for their four-ram loader linkages (with ‘parallel lift’).

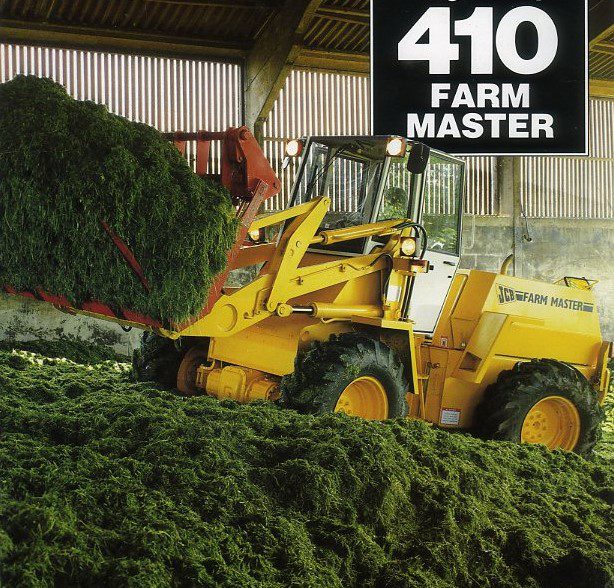

The first 410 Farm Master (pictured below) was launched in 1983, thus “continuing a relationship with the farming community that was established with the company’s foundation in 1945”.

Another noteworthy variant was the military-spec 410M (pictured below). It arrived on the scene in 1984. It differed from other versions in several key aspects.

Interestingly, a significant number of these have ended up on farms not just in the UK but here in Ireland too – having been unearthed at specialist auctions and fleet disposal sales.

JCB moved into the compact loader market in 1987. The 406 was its first such machine; it was also the first JCB-designed loader to have the cab mounted on the rear section of the articulating chassis. It was joined by the 408 in 1989 and the 408 Farm Master in 1990.

In 1994, JCB went on to re-design its ‘heavier’ loaders, with the launch of machines like the 411, 412S and 416. These also had a cab on the rear section of the (pivot-steer) chassis. The rest – from the mid-to-late 1990s onwards – is recent history!

Loader poll

AgriLand hosted a poll early last year, in which we sought your input and views to find out what machine was held in highest esteem – as the iconic Irish ‘silage’ loader.

Also Read: Results are in: JCB Farm Master tops the pollIt was a light-hearted and nostalgic look at loading shovels – specifically at those machines that have shaped the Irish silage-harvesting landscape during recent decades.

At the time, we came up with a list of seven possible contenders – not definitive or exhaustive by any means, but representative nonetheless of ‘milestone’ machines that would be familiar to agricultural contractors and their operators – up and down the country.

- Caterpillar (CAT) 910;

- Clark Michigan 35B;

- JCB 414S Farm Master;

- Komatsu WA320-5;

- O&K L25;

- Venieri (VF) 9013;

- Volvo BM L70.

By the close of the poll, over 2,200 people had voted. The JCB 414S Farm Master topped the bill – taking 45% of the votes cast.

Next up was the Volvo BM L70; it attracted 24% of the votes. It was followed by the Caterpillar (CAT) 910 – at 12%.

The other machines – the O&K L25, Clark Michigan 35B, Komatsu WA320-5 and Venieri (VF) 9013 – accounted for the remaining votes, but were down the field.