Scully Trailers of Killorglin, Co. Kerry, was founded by Niall Scully, who has been manufacturing for farmers for over 15 years.

Recently, Agriland took a trip down to the Kingdom to find out more about Scully operations.

A new appreciation

Trailers are rarely the greatest item of immediate interest to farmers, unless they are suffering from a flat tyre or other mishap, yet that is changing as, out of necessity, they start to become more complex.

Complexity and farm trailers appear to be conflicting concepts, yet a few girders, some sheet steel and an old lorry axle stitched together with a boxful of welding rods just doesn’t make the grade today.

Larger tractors capable of hauling heavier loads at faster speeds has meant that trailers need to be stronger and better equipped to meet the extra demands placed on them, as well as comply with an endless stream of legislation.

Going upmarket

With this extra sophistication has come greater expense and with that, has come an increasing demand for trailers to reflect the investment made in them, according to Niall.

Trailers, first and foremost, need to be functional and do the job expected of them. They also need to be well engineered and put together, but, as Niall has increasingly noticed over the past few years, customers are also looking for a certain style element to be included as well.

Spending a vast sum of money on a tractor only to hook a tatty trailer to it is no longer as acceptable as it was and so, in addition to the purposeful engineering, there has to be a sense of design that stands them above the ordinary.

Pioneers of design

Tractor manufacturers have known this for years; John Deere led the way with the appointment of Henry Dreyfuss as its style Guru in the 1930s, leading to the classic art-deco lines of its then product range.

Niall trained as a fabricator and so the products feature all that is right from an engineering point of view.

However, he has also taken a leaf from the tractor manufacturer’s book and includes design details which elevate the products above the average offering.

Chief amongst these is the rolled deck edging. Instead of having the deck sheet end at the edge of the trailer, it is curved round and down the side of the longitudinal member.

This not only adds strength and rigidity to the structure, but lends greater protection to the trailer underside from water ingress.

It also looks good, as do the ‘eyebrows’ above the tyres and care to protect the decals by surrounding them with a bead of weld.

Market position

It might be thought that the time and expense spent on these trailers would make them uneconomic to build or buy. Niall admits that he considers them a premium product, but notes that he also has a waiting list.

The level of design and finish of these trailers might suggest an ultra-modern studio-type manufacturing facility on a trendy industrial park somewhere. That, however, is not the case at all.

The company is proudly based on the family dairy farm with most of the fabrication facilities on site, the major exception being the laser cutting which is subbed out to a local firm which works closely with them in creating the products.

All the other cutting, welding, turning, folding and painting is done in situ.

This self-reliance even extends to a shot-blasting shed where the metal is prepared for the two-pack paint finish, a facility which is currently being upgraded to increase its efficiency.

Scully bale handlers

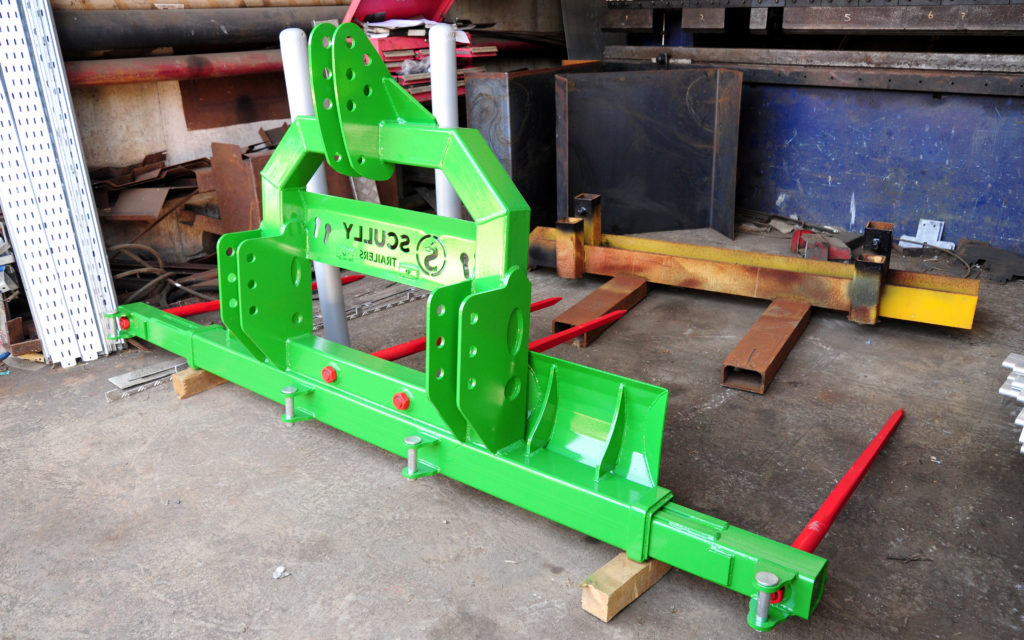

The thought that goes into creating trailers is also applied to the other items in the company’s range, chief of which are bale handlers.

The firm produces three distinct model lines. There are the standard rear-mounted spikes with roller covers, the paddle or soft-hand type and finally, the overreach or elephant variant.

All share the same attention to detail that is exhibited in the trailers, especially the overreach handler.

On this product the ram and check valve are positioned and protected from damage while the bale is pressed against a sturdy ‘lip’, rather than a shallow length of angle iron.

The rollers are also greased from the end rather than through a hole in their sides, which minimises the chance of damage to the grease nipples.

Hinged handlers

Bale handlers are simple devices with little room for innovation, or so it might be thought, yet Scully Trailers have found a way of taking them forward by adding a hinge.

By doing so the paddles, rollers or spikes, can be folded up and away, allowing the hitching of a trailer with having to remove the handler.

Besides this obvious advantage, another benefit is that it allows the loading tractor in the field to gather two or more bales at a time, with the bale at the rear acting as a counterweight, adding to stability and safety.

Moving forward

Niall is not one to stand still; having built a name for his company in manufacturing solid and reliable equipment he is continuing to invest in the premises and his staff.

Besides the upgrade to the shot-blasting facilities he is considering solar panels to help reduce his electricity bills and is always looking to update the workshop machine tools.

Yet it’s not just about the hardware, he also takes on apprentices and encourages them to gain experience in all aspects of working with metal.

It is this sort of enthusiasm for both the product and his staff which will stand everyone concerned in good stead as the machinery industry continues to evolve.