This week’s Buildings Focus sees Agriland make a trip along the Windy Gap in Co. Mayo to speak to Ciaran and Carmel Reilly about their new slatted sheep shed.

The husband-and-wife team, along with Ciaran’s father – who plays a big role in the day to day operations on the farm – run a flock of 200 ewes and at the time of Agriland’s visit, lambing was winding down.

Up until this year, the Reillys had been housing their flock of ewes in a four-bay shed that had timber slats about a mile and a half away from the main farmyard.

Having the sheep housed away from the main yard made life that bit more tricky and more labour intensive. So, having used up some of the Targeted Agricultural Moderisation Scheme (TAMS II) money on replacing slats in their beef shed, the Reillys decided they would use the rest to build a modern sheep-housing facility in the main yard.

Speaking to Agriland inside their new sheep shed, Ciaran and Carmel Reilly said: “We wanted to streamline the sheep end of things and have all our stock in the one yard.

“The old sheep shed served us well and did the job, but it was very labour intensive and we wanted to make life that bit easier for ourselves.

“We had already made use of the TAMS and we felt that we might as well make the most of it, use it up, give ourselves some comfort and have all the ewes and cows in the one yard.

“It’s not just being able to have the ewes there for lambing, the shed is set up for us to be able to do other jobs and so far, we are nearly at the end of lambing and it has been a dream to work in.”

Layout

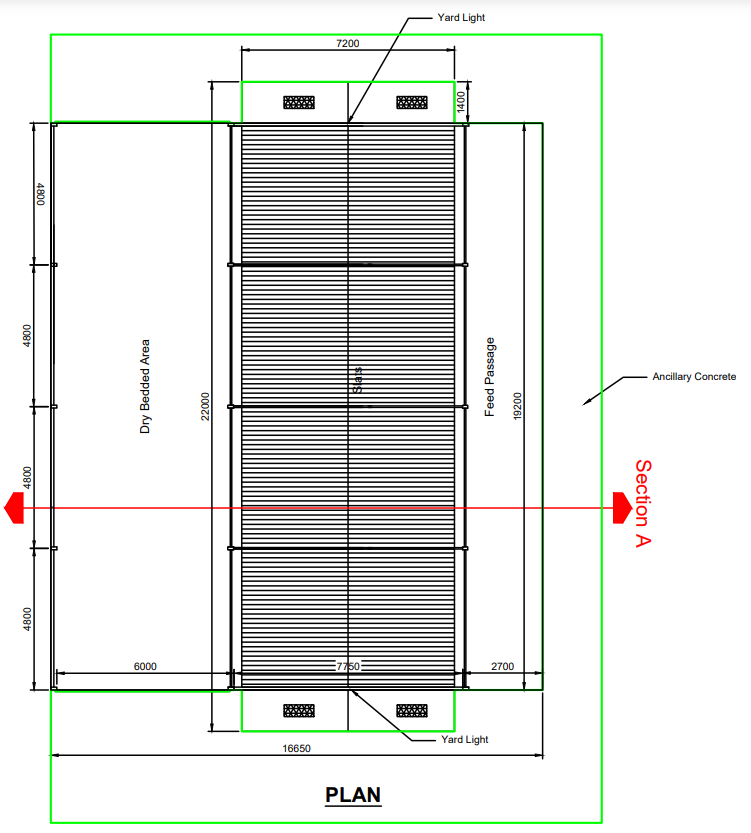

The new sheep unit is a four-bay double – back to back – with a feeding passageway either side and a space to set up individual pens.

The design and TAMS application was all completed by Carroll Consultancy Agricultural and Business Consultants in Co. Mayo.

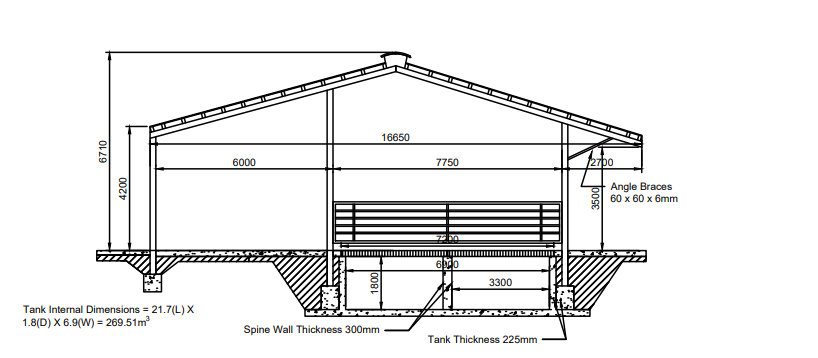

The shed measures 19.2m long and 16.65m wide. The double slatted tank is 7.2m wide, 22m long and 8ft deep.

The shed stands 6.71m to the apex and 4.2m to the eaves.

The reason for the extra depth to the tank is to increase the slurry capacity on the farm, as the Reillys said that they have previously been tight for slurry storage and looked to rectify this problem with the new build.

The feeding passageway inside the shed, which is down in the drawing as the dry bedded area, acts as, already mentioned, a feeding passageway, but also is where individual pens are set up for lambing.

There is also a washing area and storage space which is stocked with lambing essentials.

This ‘dry bedded area’ measures 19.2m long and 6.0m wide and can be accessed through two sliding doors at either end of the passageway.

There are eight slatted pens for sheep to reside in. Four of the pens, two at either end of the shed, measure 3.87m wide and 4.7m long; the four pens in the centre of the shed measure 3.87m wide and 4.4m long.

Two walkthrough feeders were also incorporated to increase feeding space; they measure just over a half a metre wide.

On the other side of the pens is another feeding passageway, faced out onto the open, with a canopy protruding out over it. This feedspace is 2.7m wide and 19.2m long.

The canopy stands 3.5m from the concrete floor and exerts 2.7m out over the feeding area.

Inside the slatted sheep unit

Taking a look inside the shed, Ciaran and Carmel incorporated some nice features to the shed, in terms of making it a safe and labour-friendly environment to work in as well as a comfortable place for ewes to be housed in.

The Reillys had already been using slats to house their ewes on, the difference being they had used timber slats up until they moved in to the new shed which has platic slats in it.

Both said that the timber slats weren’t that durable and often had to be replaced.

However, having seen the benefits of slats and noting the difficulty they would have in sourcing straw where they are based to keep enough under ewes during the housing period, the idea of going with a dry bedded shed never entered their minds.

So, they opted to go with plastic slats sourced from Gary Sproule and have been very happy with them to date.

Two important aspects of the shed design to the Reillys was the amount of lying and feed space that ewes could have access to.

Ciaran and Carmel said that the four pens, two at either end of the shed, can fit approximately 17 ewes each comfortably, with the four pens in the centre of the shed fit to hold 15 ewes each.

Ewes can feed out from two sides on the pen – this is across all eight pens. To make this possible, the Reillys incorporated two walkthrough passageways which connect both the main feeding passageways in the shed.

With regards to the four pens on either end of the shed, the plan was to install the small water troughs onto the wall; however, the Reillys were advised, by Stanley Engineering Services, to install them along by the walkthrough troughs.

The idea behind this was that if the drinkers were dirty they could be cleaned from the walkthrough passageways by leaning in, without having to enter the pen. Again a simple, but time-saving idea.

In the case that a ewe lambed in one of the slatted pens, stockboarding was fitted onto the dividing gate and falls down to just above the slats to prevent the lamb moving from one pen to the next.

Adjustable feed barriers were hung at the front of each of the pens. In many sheep units, the feed barriers have a small access gate incorporated onto it to allow for entry in and out of the pen. All barriers in the shed are lamb proof.

Generally, the feed rail and gate are incorporated all in one – to offer greater strength – with a step at the bottom of the gate that you would have to step over when entering the pen.

However, the Reillys wanted the feed barrier and small access gate to be separate from each other and to have it where there would be no step between the passageway into the pen.

Ciaran and Carmel said that it’s not just safer for them but for anyone working in the shed, in that they can rule out the risk of anyone tripping over.

Furthermore, it’s easier as well for ewes to move to and from the pen, in such a case if a ewe was after lambing and was being moved into an individual pen.

Moving away from the slatted area, also under the roof of the shed is one of the main feeding passageways as well as a place where individual pens are set up and a wash up/storage area.

The feeding passageway is wide enough for a tractor to come in and drop in a bale or, in the case of the Reillys, a block of silage from the silage pit opposite the shed, as well as being able to set up individual pens.

Once lambing is over, the individual pens will be tidied away and this multipurpose area will be used to set up the mobile sheep-handling unit in summer.

On the other side of the shed, an open feeding passageway can be found that faces out to the yard.

A cold breeze can swing into the shed, entering from this open side. So, in order to break that breeze and prevent the sheep from getting a chill, two sliding doors were fitted.

Lastly, another downside to the old slatted shed was that a camera couldn’t be installed to keep an eye on ewes that were lambing so a few trips, at the height of lambing, had to be made to check in on them.

Therefore, to avoid having to make as many trips down to the new shed, the Reillys installed a camera to keep an eye on their ewes – and that can be done from the comfort of their mobile phones.

Cost

The shed was completed in December of 2021, with sheep first being introduced to the shed at scanning time. The build took four months to complete.

The Reillys dug out the site themselves, with the help of the family business – Joe Reilly Plant Hire.

Alan Ryder stood the walls of the tank and shed, as well as laying the concrete floors of the passageways and around the outside of the shed. Liam Armstrong fitted the agitation points.

North West Tool Hire supplied the shed, while Stanley Engineering Services kitted out the inside of the shed, while E solutions completed all the electrical work.

From making use of the TAMS and also reclaiming VAT the Reillys, having said so themselves, were left with a fine spec shed at a relatively reasonable cost to them of €54,500.

They were lucky in their timing in terms of sourcing materials for the shed and completing, or giving a helping hand in the construction of the new build the whole way throughout themselves and with the help of family, which helped to bring the cost of the project down.

Speaking about the decision to start building when they did, the Reillys said: “We were lucky and unlucky you could say.

“What helped keep costs down was that we did a fair share of the work ourselves, such as digging out the site for the shed and helping the building contractor lay down the walls for the tank, the concrete around the shed and standing the frame of the shed.

“So that helped big time. To say we didn’t get stung by the increase for the building materials would be a lie.

“We priced steel in early in 2021 and then left it until May and by the time we came to buy it then, it had gone up €8,000. We put a deposit down then and there just to secure it and save ourselves from it getting any dearer.

“Overall though, we are very happy with how it turned out. It has made our lives so much easier and it’s not only for ourselves, but if any of the kids ever want to make use of it, it will be there for them too.”