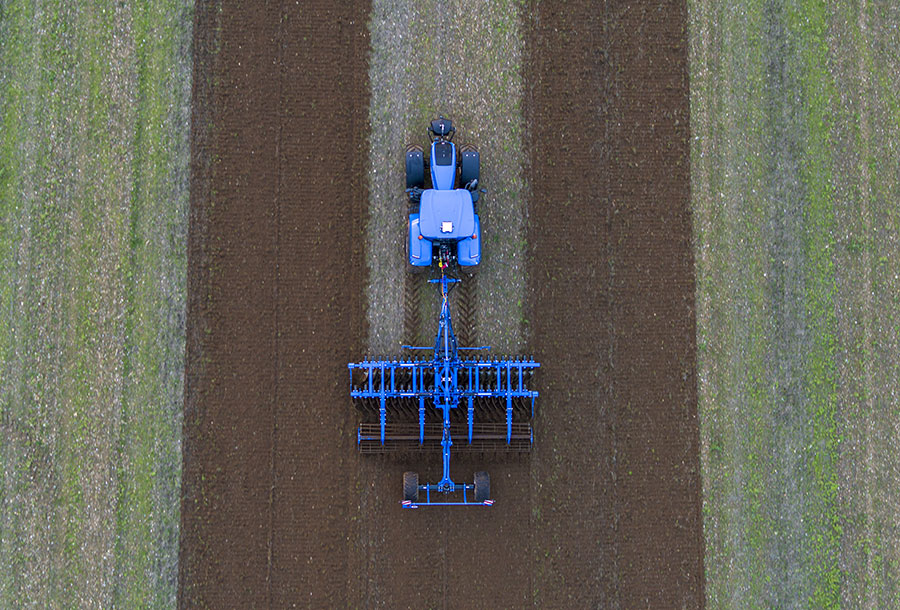

New Holland have added a range of Compact Disc Harrows to their tillage offering.

The compact disc harrow has multiple purposes, including: stubble cultivation for harvest, cover crop incorporation and seedbed preparation.

Compact disc harrows are ideal to make shallow stubble cultivation, blending in stubble and residues to ensure the breakdown of the organic material is started quickly, and to create a stale seedbed to let harvest losses germinate.

The benefit of a disc harrow is that it does not plug in high residue conditions or when cover crops are knocked over.

The ideal working depth for the compact disc is in the range of 3–12cm (maximum 15cm) depth and, with working speeds of up to 15km/h, the compact disc is a high capacity implement which gives a high work rate per hour.

When the compact disc harrow is used as seedbed preparation before planting, the discs have the added benefit that they will cut soil clods and mix all soil types. The rear packer roller’s crumble the soil but also reconsolidates to prevent unnecessary dry out, which is key for a good seedbed.

SDM versus SDH

The New Holland SDM compact disc harrows are equipped with a 510mm diameter disc. The disc has a concave shape and a notched edge which gives good cutting ability and ensures they follow the ground well.

The disc is fixed in a rubber suspension which allows a vertical movement of 100mm to pass stones or other obstacles.

The New Holland SDH compact disc harrows are equipped with a 610mm diameter disc. The disc is has a concave shaped and a notched edge which gives good cutting ability and ensures they follow the ground contours.

The disc is mounted on a C-shaped spring which gives good clearance and allows to handle extreme amounts of residue. The spring design also allows a vertical movement of 200mm to pass stones or other obstacles.

Compare the New Holland SDM and SDH models bellow:

Note for above table: Models with an ‘R’ are rigid frame; models with a ‘T’ are trailed and hydraulically folding models; models with no letter have a hydraulically folding frame.

New Holland roller options

Cage Roller

This is used on a medium mix/dry soils where it gives excellent seed bed preparation and surface levelling.

It’s available for SDM Mounted with a diameter of 450mm and for SDH Mounted with a diameter of 550mm.

Double Cage Roller

The SDH Trailed can be equipped with a double cage roller that makes a “mulching effect “for a perfect refinement of the soil and the mixing of residues.

The pendulum hinge system allows the roller to follow well the ground and an accurate depth control on any terrain.

Each roller has a diameter of 400mm.

Ring Roller

This roller is suggested for sandy-loamy soils, it provides a soft upper layer of fine soil and a lower compacted layer to get well-developed plant roots.

It’s available for all models SDM and SDH, and has a diameter of 600mm.

Double U Roller

This roller is versatile and good for levelling and consolidating wet land without excessive compaction.

Compact and open bands work to consolidate the soil but avoiding the formation of soil crusts or stagnant water.

It’s available for SDM Trailed and has a diameter of 560mm.

The table below shows the which different models can be equipped with the rollers.

Front Roller

The trailed SDM units can be equipped with a front blade roller. The blade roller will partially chop the residue and cover crops before passing through the disc section. The blade roller also has a crumbling effect on clods and chop these when the unit is used for seedbed preparation.

The blade roller has a hydraulic depth adjustment which can be controlled during operation.

Note: An additional double acting hydraulic outlet will be required.

Front Depth Wheels

The SDM Trailed can be equipped with an additional front wheel, it helps to increase stability during working and precision in depth control.

For more information on New Holland’s tillage equipment, click here.

Or, contact your local New Holland Dealership.