A recent Teagasc study looked at the milking time distributions on Irish dairy farms. 37 commercial dairy farmers were involved in the study, which collected data in May 2014 and May 2016.

At last week’s International Agricultural Workforce Conference, Teagasc’s Dr. John Upton discussed the key findings from the work.

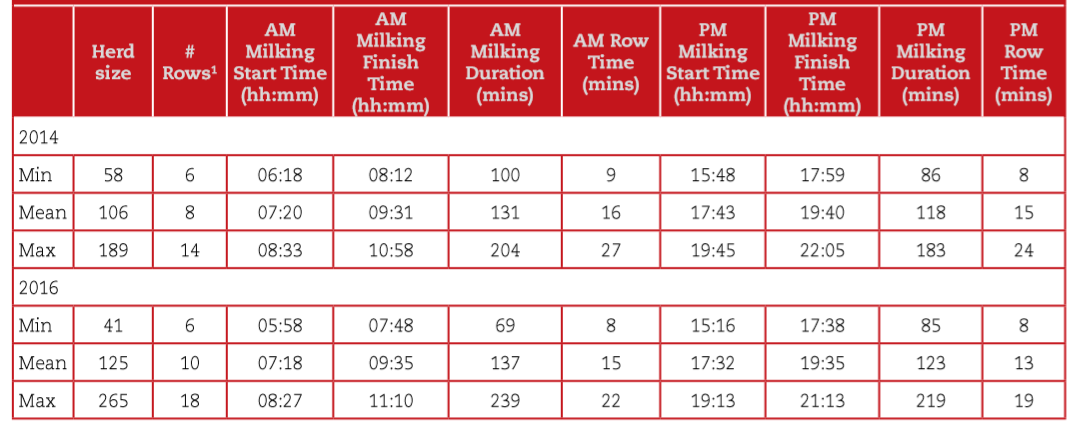

During the period from 2014 to 2016, herd size increased from 106 cows to 125 cows on the farms involved. There was an overall trend towards increasing herd size, he said, with just four farms reducing cow numbers.

Most farmers in this study started the morning milking between 6:30am and 7:00am (35%); the average morning milking duration was 134 minutes.

Morning milking start and finish time distributions for May 2016 from 37 farms. Graph source: Teagasc

Meanwhile, he said, most farmers in the study started evening milking between 5:00pm and 5:30pm (24%). The average evening milking duration was 120 minutes.

Evening milking start and finish time distributions for May 2016 from 37 farms. Graph source: Teagasc

Upton explained: “The average daily milking time of the sample of farmers was about 260 minutes; there’s definitely scope for improvement in terms of labour utilisation and milking efficiency.

“It’s important to remember that the 260 minutes does not include fetching cows, returning cows to the paddocks or feeding tasks. You’re talking about 60-90 minutes extra everyday to accommodate those extra tasks.

“The total daily milking duration only increased slightly from 2014 to 2016; it increased by about 11 minutes. What’s driving that is an increase in the number of rows milked. In 2014, there were eight rows of cows to be milked on average. In 2016, there were 10 rows of cows.

“We saw a reasonably tight spread in terms of morning milking start and finish times, but we also have a large number of farmers milking very late in the evening.

About 30% of farmers started milking after 18:00 and 11% were finishing after 9:00pm. On average, 5% of farmers were finishing milking after 10:30pm consistently, for the month of May, over the course of this study.

Cows per hour

Upton also said that the average number of milking units on these farms was 14; that has stayed consistent across the years.

“If there’s good news there it’s that the row time decreased by one minute on average from 2014 to 2016, so farmers are milking more cows per hour.”

Despite this, the average number of cows milked per hour is “still not that impressive”.

“The average number of cows milked per hour across these farms was 57 (ranged from 32 to 101), which increased from 51 cows per hour back in 2014.

“Really what’s driving the decrease in row time is probably just operator efficiency in the pit because it’s not extra milking units,” he said.

Minimum, mean and maximum milking start-times, milking finish-times and milking durations for morning and evening milkings during May 2014 and May 2016. Table source: Teagasc

Areas of improvement

The Teagasc representative also discussed a number of methods farmers can use to reduce the amount of time spent in the parlour.

Increase the number of milking units

Upton said that the number one way of speeding up the milking process is to increase the number of milking units.

“Try to have a maximum of 10 rows. We saw that the average row time was 14 minutes, so – in my view – 10 rows would be too many.

“Ideally, if you’re building a new milking machine, starting from scratch or adding in new units, you would be looking to achieve six or seven rows.”

Cow flow has a massive effect on milking efficiency. He said: “By cow flow, we are just talking about efficient movement of cows through the parlour.”

“Small incremental efficiency savings that you can gain in each row all add up over time to give a time saving at the end of the day.

“The average row time of this study was 14 minutes and there’s definitely potential for improving that. Basically, the milking routine is a major thing and a lot of farmers have received very little training on it. “By milking routine, we mean moving the farmer or milker around the pit. We must make those movements as few and as efficient as possible,” he said.

“Any changes to vacuum, liners or clusters have a direct effect on the milking speed and row time,” he said.

“But changes in this area should definitely not be made without some consultation with your milking machine technician. While vacuum, liners and clusters can be used to increase milk speed, that’s not really the best practice recommendation.

“For me, the most important milking machine factor – in terms of increasing milking efficiency and decreasing row time – would be related to the cluster removal take-off settings; that’s where the savings are basically made.

“By increasing the cluster removal threshold from 0.2kg/minute – our traditional end of milking set point – back to 0.8kg/minute – which has been tested by a number of organisations in New Zealand and shown not to affect cell count – would save 72 seconds off milking one cow.

“Over 10 rows, you’re talking about 14-15 minutes a day of savings,” he said.

Reducing row times

Milking machine factors