Adrian Morris is currently milking 50 British Friesian cows on his farm in Co. Cavan. Adrian is the second generation to farm there, with his father’s farm being established in the 1960s.

There may be a potential for a third generation of Morris dairy farmers with one of Adrian’s daughters, Nicole, showing a keen interest in the farm.

Two years ago, Adrian began filming videos of his farming life with his wife and five children, and uploading each video on YouTube.

He began his YouTube channel to give viewers a genuine perspective of how a dairy farm operates in hope to encourage the next generation of farmers.

Today, his YouTube channel, IFarm WeFarm, has over 60,000 subscribers.

Silage production

Typically, forage consists of anything between 40% to 80% of the diet in most dairy and beef production systems.

Adrian aims to make his first cut of silage during the last few days of May and will make his third and final cut at the end of August.

Commenting on unprecedented fertiliser prices and current grass growth, Adrian said: “Considering the price of fertiliser, we want to have a balance of quality and quantity so we’re still aiming to have our first cut done between May 25, and end of May.”

Adrian produces both pit and baled silage. Overall, the dairy farmer aims to harvest 30ac in his first cut, 25ac in his second cut and 25ac in his third cut.

“Our second cut tends to be bales but we have also put it into the pit which depends on what the pit is like and what it’s like in the first cut. If we’re satisfied with the first cut, we will do our second two cuts in round bales,” said Adrian.

Covering the pit

Previously, Adrian had issues with excess wastage from his silage pits due to using lower-quality covering materials. Traditionally, when covering his pit, Adrian used three plastic covers with 800 tyres on top only.

Commenting on how he had previously installed the pit, Adrian said: “That worked well, we always had a bit of waste, along the sides and around the front of the pit especially.”

The average amount of waste on a poorly sealed clamp is 8cm on the top and sides, with more than this on the shoulders. This means waste could cost up to €4.80/m2. On a 16m x 50m clamp, this could add up to €3,840 in losses.

In comparison, the cost of Visqueen Clingseal to cover the same size of clamp is €215.00, which is €0.268/m2.

When changing to Rhino’s products, Adrian decided to film the entire silage production process to give viewers an insight into his silage-making process, and how Rhino’s products performed.

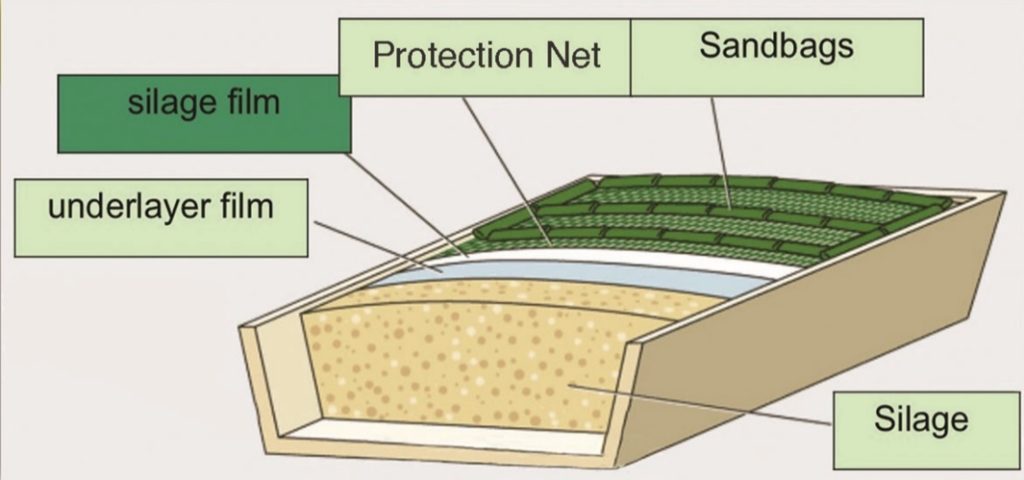

Speaking about how he now covers his silage pit, Adrian said: “First of all, we use covers across the walls and use the Visqueen Clingseal along the top. Clingseal is strong enough to walk on which makes it easier to complete the pit.

“Then, on top of the Clingseal, we used Rhino’s premium 400g black plastic silage cover and then Rhino’s green protection net on top of everything.”

Rhino protection nets are available in the following sizes: 5x10m; 8x10m; 10x12m; 10x15m; and 15x20m.

Rhino protection nets have ties and handles which allow the farmer to secure the nets easily with Rhino sand bags.

The protection nets keep the silage safe and keep the plastic tight along the sides of the pit and along the joints. The protection nets also protect the pit from birds and pests.

Adrian found that covering the pit was a lot easier after he decided to make the change from covering the plastic with tyres to Rhino sand bags.

He said: “We prefer the sand bags as you need less quantity of them, they’re cleaner, and far easier to work with.”

Durability

Adrian has found the combination of Rhino’s protection nets and Visqueen Clingseal clamp sheets to be far more durable and effective than similar products he used in the past.

Farmers and industry experts use Visqueen Clingseal, a flexible vacuum sheet that is used directly beneath traditional, heavier silage sheets.

It is thinner and therefore more flexible, allowing it to cling more closely to the contours of the clamp surface and tuck-in more at the sides. This helps eliminate air pockets and provides a close fitting barrier to significantly reduce top and shoulder losses from aerobic spoilage.

Speaking about the durability and ease of using Rhino’s protection nets, the dairy farmer said: “We use three sections on our pit and it’s very light-weight, so it’s easy to take off, and it’s reusable for several years as long as it’s looked after.”

Silage quality

Viewers of Adrian’s YouTube channel got the chance to see Adrian’s first impression opening the pit after using Rhino’s products for the first time.

As Adrian runs a dairy farm, producing high-quality silage is of highest importance in terms of reducing concentrate costs.

“I was as nervous as anybody, and I think viewers saw my huge positive reaction as the pit was so good when we opened it,” he said.

“Overall, my impression, when we opened our silage pit to show our audience, was that Rhino’s products were the game-changer for us in terms of silage quality.

“It was responsible for us having such a good pit of silage – one of the best pits of silage we’ve ever had,” said Adrian.

Adrian was extremely pleased with how little waste was produced, saying that: “We had next to zero waste, just a small bit at the very beginning, which was very, very small – maybe two or three barrows worth.

“We definitely had no rot in our pit when using the Clingseal and protection nets, and the fermentation seemed to be very good.”

As it provides a better air seal, Visqueen Clingseal also facilitates a faster, more efficient fermentation process – delivering enhanced clamp silage quality.

lt is also easy to apply, and suitable for a variety of ensiled crops, including grass, maize, wholecrop and other moist feeds.

Animal performance

Following the use of Rhino’s products, Adrian mentioned that there was a notable improvement in silage quality and in his herd’s condition.

Feed as a whole represents the largest single cost in these farming systems; reducing losses and maximising silage quality is the priority, and Visqueen Clingseal can do just this.

“We didn’t have to feed any concentrates, apart from only a small amount in the milking parlour. The cows fed that pit of silage are in extremely good condition, with which our viewers have even commented on.

“Anytime you have good silage it will always save you on concentrate costs,” mentioned Adrian.

Adrian is looking forward to the upcoming silage season and to using Rhino’s products again this year.

“Using the products was a complete success. If anyone wants to check out the entire process, they can watch it on my YouTube, IFarm WeFarm,” he concluded.

For more information on Rhino’s products, click here.