As Irish dairy farms continue to grow, more and more farmers are exploring the potential of robotic milking.

While these systems can be extremely successful, planning is the most important stage when considering robotic milking on a grazing platform and there are many factors to consider.

It is not only the physical things which will require change, but also working routines and lifestyle changes. Below you will find some of the main facts to consider and apply to your own farm.

Any farmer thinking of installing a robotic milking system – with grazing – will need to remain open minded to the change that comes with it.

Changes come in the form of: new equipment; new daily routines; and new challenges. These challenges will take some time to overcome and time will be needed to adjust.

Your labour allocation will differ compared to a conventional milking system. Your time will become more flexible, allowing you spend time on routine tasks such as focusing on improving cow health and performance which may have been neglected before.

Farmers will have the opportunity to plan routine tasks around lifestyle and seasonal demands – maximising overall robot, herd and labour performance.

For example, plan your preventative maintenance visit before your calving season starts, as maximising robot performance during the peak milk period will reduce the risk of unplanned downtime.

“Our entry into dairying has changed our daily work routine significantly, but so far our DeLaval VMS has provided us with the flexibility to look after our cows and crops in tandem,” explained Co. Laois-based dairy farmer, James Brennan.

Grassland management is the most important factor when installing a robot on a grazing platform. The promise of fresh pasture, concentrates or a buffer feed at the robot is what encourages your herd to voluntarily move around your system, while visiting the milking centre regularly.

Grazed grass is the lowest cost animal feed for milk production and it should be managed correctly to ensure it is of the highest quality.

In addition to grass quality, allocating the correct amount of grass to the herd is also crucial to achieving good cow flow.

When doing this, consideration needs to take place around the cows’ total dietary requirements, accounting for any supplementary feed that is being offered. Understanding this – along with the quantity of the grass in the paddock – enables the farmer to strike the correct balance between feed and traffic management.

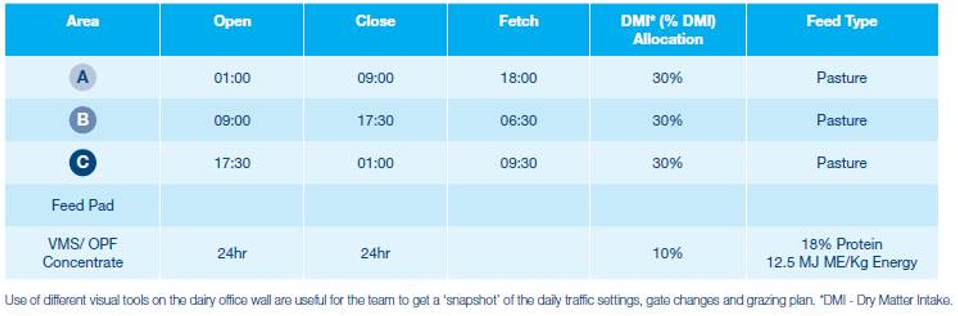

When the farm is divided into three similar-sized farmlets, the cows have the ability to access each farmlet for grazing for approximately eight hours each over a 24-hour period.

With some cows spending longer than this in a given section, these parameters will give cows the ability to traffic through the grazing yard at a minimum twice every 24 hours, as they try to access fresh pasture.

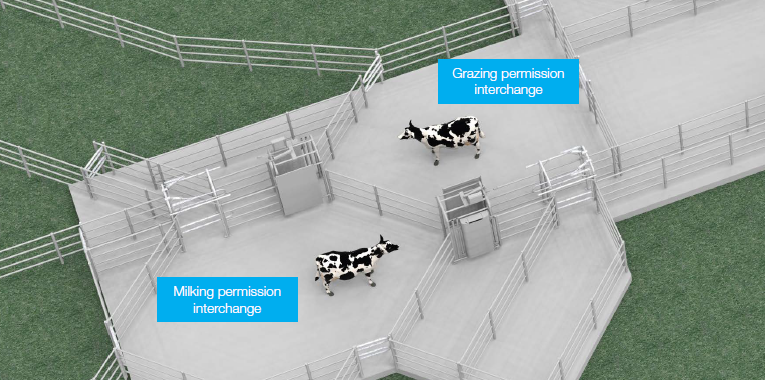

The DelPro™ Farm Management System and smart selection gates determines if a cow is ready to be milked, which can be based on either time, expected milk yield or a combination of both.

- Treat each grazing area as a separate farmlet;

- Use strict pasture management principles;

- Learn to allocate the right amount of pasture for each grazing round (by measuring the difference between pre and post grazing residuals);

- Over allocation = cows less likely to leave paddock;

- Under allocation = cows leave earlier than desired, causing congestion in

milking centre; - Weather conditions can influence dry matter intake (DMI) – plan accordingly.

“The DeLaval guided system gave us more flexibility than others and ABC grazing was easy to incorporate for us,” says Limerick dairy farmer, Simon Butler.

With no two farm layouts the same, walking distances from the grazing yard to the furthest paddocks will vary between each grazing section.

Cows should be offered paddocks during the daylight hours and long walks should be alternated with short walks to balance out commuting time over a 24-hour period.

Furthermore, encouraging traffic during the night time hours is of paramount importance to achieving even and successful utilisation of the robot.

To facilitate this, daily grass allocations can be organised in a manner that ensures cows are incentivised to traffic at night time hours, by offering cows a greater proportion of their daily grass allocation in their day time blocks.

More information

If you would like more information from DeLaval on how our robotic milking system – VMS V300 – works with a grazing platform, download your free guide to grazing with a DeLaval robotic milking system by clicking here