Fendt's latest take on autonomy has hybrid drive

Fendt is considered to be the leader when it comes to tractor digital technology, yet it has kept its intentions on a fully autonomous tractor rather low key.

However, that does not mean it has been sitting on its hands not thinking about the idea.

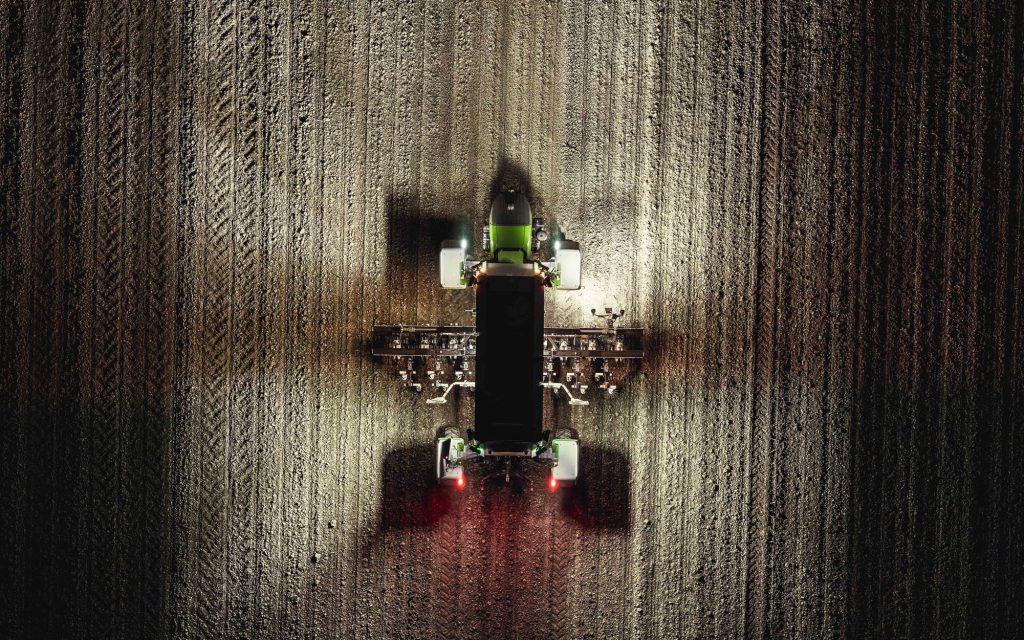

The company's contribution to the rapidly growing pool of concept machines is the Xaver GT, a 3t tool carrier that does not seek to automate a conventional tractor, but rather, it explores the option of creating a machine focused on performing field tasks.

This, in itself, is not a new idea but Fendt comes to it as a company with decades of experience in farm mechanisation rather than being just another start-up with a bright idea.

Change of direction

It also marks a significant change in the company's approach to automation, for back in 2020 it had unveiled its latest Xaver robot swarm system, which relied on fleets of small machines working in fields simultaneously.

That idea appears to have been abandoned but much of the technology that was developed has been transferred to the Xaver GT, with GT standing for Geräte-Träger, which translates to Implement Carrier rather than Grand Tourer when found on the rear of cars.

Fendt have used this designation before on various tool carrier type tractors, starting in 1964 with the F230 GT, although it was not applied to the Zylon system tractors built between 1995 and 2004.

They were not designed or intended to be used as draught machines, nor is the new Xaver GT, although it appears to be capable of light tillage.

This new machine is therefore built upon a combination of legacy engineering combined with up-to-date digital technology that has been brewing in the pot since 2017, which is when Fendt started the development work on field autonomy.

Weed control is driving autonomy

It is mechanical weed control in row crops which appears to be the main driver for automation, or at least it is this task which is most amenable to the new technology and where its cost may be most easily justified.

The resistance of weeds to herbicides, and the pressure to reduce their use from beyond the farm gate, also encourages the search for alternatives.

The essential basis for such methods is precise row guidance. Without it, hoeing close to each plant would be impossible without damaging the crop.

The Xaver GT can be fitted with a frame which can be moved to the left or right as it moves down the rows, ensuring that the hoe points are always positioned accurately between the crop plants

The track width can be adjusted to suit various farming systems while its 50cm ground clearance enables it to be used at later stages of growth.

Mid mounting for precision

The mid mounting point of the machine also has a significant benefit, beyond ensuring an equal weight distribution between the axles.

Attaching a hoe on a laterally sliding frame at the centre of the machine greatly reduces the effect on its directional stability as it avoids the leverage and rudder effect of mounting it at the rear.

This arrangement of having it within the wheelbase will increase precision as there is less disturbance to the straight line travel, enabling hoeing to take place closer to the crops.

Accurate row detection forms the basis for reliable control of the sliding frame, even in windy conditions or on uneven terrain. To this end, Fendt has developed RowPilot in collaboration with PTx.

The user interface is based on FendtONE with the normal Fendt operating concept allowing remote access to the machine via mobile phone, tablet or PC.

The tractor is here to stay

Fendt are not claiming the Xaver GT to be a replacement for the tractor as we know it.

It is seen more as an extra tool that can perform the mundane tasks between primary cultivation and harvesting.

This follows a growing trend in the pursuit of autonomy.

The desire to bin the tractor and start all over again with smart machines is gradually giving way to the realisation that it's not going to be that easy and the gradual automation of various tasks will be the way forward.

The company is firmly placing the emphasis on future field work being a collaboration between the driven tractor and autonomous robot rather than just one or the other.

Powering the Xaver

There is another feature of the machine which points to a retreat from the what was generally expected of future field mechanisation and that is the power source.

Throughout the Zaver development programme Fendt have prioritised the minimisation of soil compaction, a problem encountered by trundling any cumbersome machines around fields.

With the GT, the company has opted for a diesel hybrid drive with small supplementary batteries to boost the power when required.

This negates the need to carry a big heavy battery and removes any requirement to bring the machine home to be charged up for the next day's work.

Diesel - electric

A 25kw (34hp) generator powers a 48V electrical system although it is likely that the engine itself is bigger than this for there are hydraulic functions in addition to the electrical drive - the details have yet to be published.

Each wheel is independently steerable and is driven driven by an electric motor, enabling the Xaver GT to navigate with precision while being able to operate at speeds of up to 10kph.

Different steering modes can be selected depending on the application.

These include the standard Ackermann steering, while four-wheel steering to achieve smaller turning radii at the headland, and what Fendt describe as superimposition mode (crab steering + four-wheel steering) to counteract sideslip when crossing slopes is also available.

Safety considerations

Safety is attended to through a two-stage design. The tactile safety system, including geofence and status monitoring forms the basis for safe working in accordance with regulatory requirements.

In addition it also features an intelligent, proactive environment perception system with lidar sensors and cameras to detect potential obstacles and automatically initiate avoidance or cessation of work.