€54m spend on Linnavuori plant bears fruit for AGCO

When it comes to engine supply, AGCO has kept production firmly in the family with continual investment in its Finnish plant at Linnavuori.

This lies in contrast with CNH, which has lost direct control over its engine supplier with the floating of FPT as a separate business and then its eventual sale to Tata of India.

However, we are assured that it is business as normal with regard to sourcing engines for CNH products.

AGCO, on the other hand, have been relentless in building up the sophistication and capacity of its engine factory.

It is no longer considered just a place where they make engines but a profit centre and brand in its own right.

All under one roof

In addition to engines, the Linnavuori factory now produces continuously variable transmissions for the company along with conventional gearboxes, keeping the production of the driveline in-house where quality and product development can be more tightly controlled.

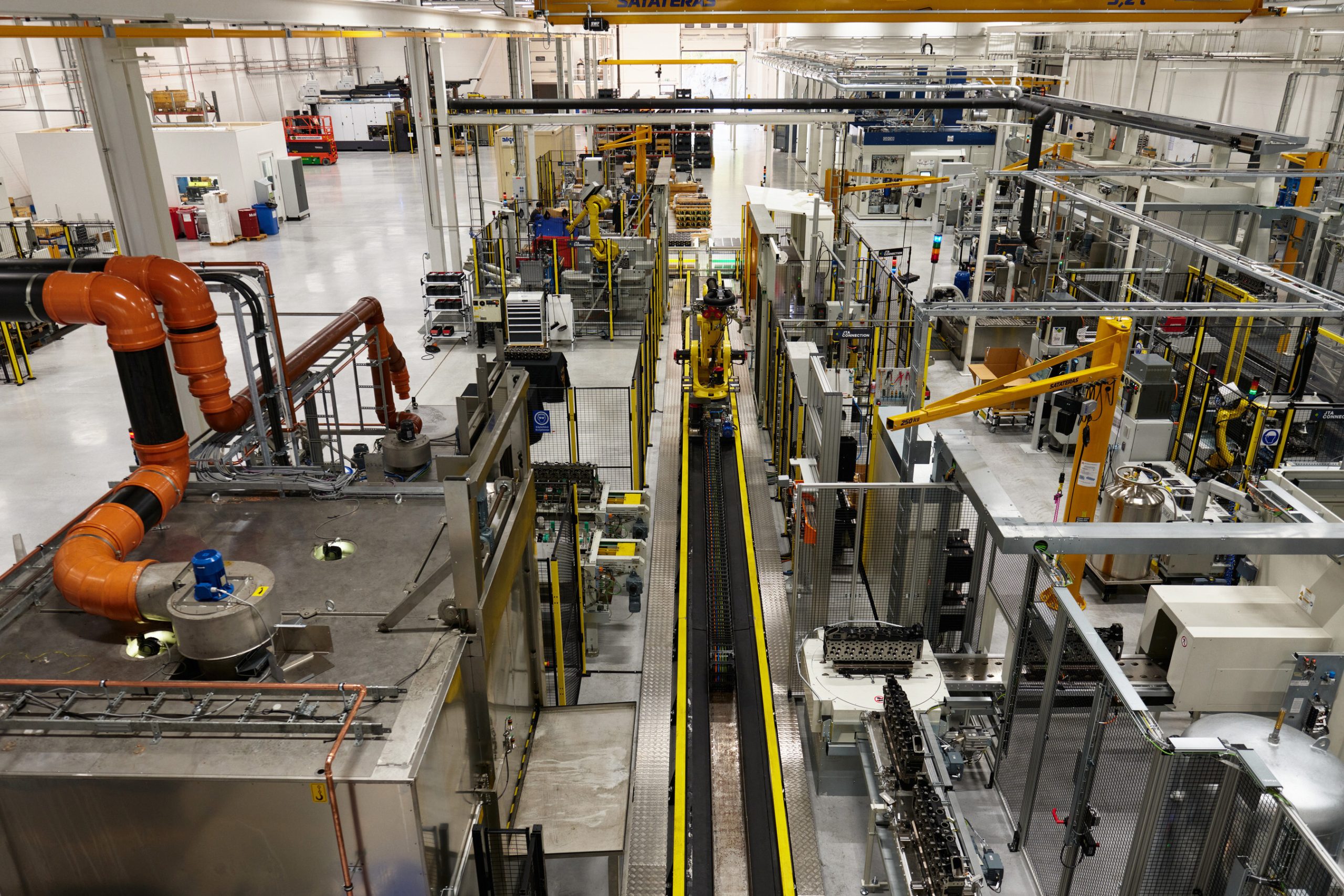

The new facilities just opened include a state-of-the-art machining hall for manufacturing Continuously Variable Transmission (CVT) components and cylinder heads for AGCO Power's latest CORE engine.

The expanded remanufacturing area also increases the plant's capacity to produce remanufactured engines, a growing segment of the machinery industry.

Long history

The company claims that it has been refurbishing engines for over 50 years, with systematic remanufacturing starting in 1990.

Yet it is possible to trace that legacy back further for Massey Ferguson-owned Perkins for nearly 40 years and Perkins had been remanufacturing its own engines since the war.

The rebuilding of engines requires experience and expertise within the workforce, as each engine is reassembled entirely by a single technician, a knowledge that is acquired working within the production process.

Today, over 1,000 engines are remanufactured annually and, with the new facilities now open, the potential capacity has risen to 2,500 engines per year.

Linnavuori expands role

Aside from engine and driveline production, Linnavuori also makes petrol engine blocks and marine engines.

The facility has a further function within the corporation, for in 2024 AGCO Power also opened a clean energy laboratory at the site, where future engine technologies are designed and tested.

There is little doubt that the Linnavuori plant has become an important part of the AGCO corporation, underlining the company's belief that the engine is still the heart of the tractor.

While other manufacturers may be of the opinion that digitalisation is the key to future success, AGCO are reminding us that applying power to the land remains the core function of a tractor manufacturer.