Located just a stone’s throw away from Ireland’s dairy heartland, Salesian Agricultural College offers a wide range of practical training courses and programmes to almost 500 students annually.

The backbone of the college’s work revolves around practical training through the use of its 260-cow dairy herd, 40-cow suckler herd and flock of 150 March-lambing ewes.

All three of these enterprises have undergone major changes since Derek O’Donoghue was appointed to the role of principal. The most notable changes, however, have been applied to the college’s dairy herd.

Previously, Derek explained, the college was home to a herd of 190 pedigree Holstein Friesian cows, producing 1.6 million litres of milk annually.

However, the decision was made to change the focus of the dairy enterprise and to bring it in-line with a Teagasc-advocated, grass-based, spring-calving system.

In January 2017, the pedigree herd was dispersed to allow the college to transition towards a more commercially-focused method of production. High-EBI, Friesians and crossbreds were the order of the day to achieve this target.

As it stands, the Pallaskenry herd is in the top 1% of the country for EBI. Each cow’s target is simply to produce 5,000L of milk and 500kg of solids from a grass-based system.

Touching on the breeding season, Derek said: “The farm uses daughter-proven bulls with a calving difficulty of less than 2% on the heifers, while mostly genomically-tested bulls are used on the cows.

“Heifers in the herd are synchronised used a PRID and fixed-time AI system, with stock bulls used to pick up the repeats in the herd.”

Derek was more than happy with the conception rates achieved on the farm this year. Cows were scanned on July 25 and after a 12-week breeding season, 236 cows were in calf and a further 22 are to be scanned in September.

Of the cows served long enough to give an accurate scan result, two were empty, two were unfit for breeding and one embryonic death was recorded.

Meanwhile, after nine weeks of breeding, 64 of the college’s heifers were in calf. 64% of those served held to fixed-time AI, while an overall pregnancy rate of 94% was recorded for the herd’s replacements.

A challenging summer

Like many farms throughout the country, Pallaskenry was hit by this summer’s drought. As a result, some of the farms second-cut silage was zero-grazed and offered to the cows.

To bridge the gap between the cows’ winter demand and supply, Derek opted to purchase wholecrop wheat to fill one of the pits in the yard.

The purchasing of this 21ac standing crop, along with a second cut of 70ac, provided the farm with the majority of the feed it needs for the upcoming winter.

The recovery after the drought, Derek explained, began on August 4, when the cows were returned to full-time grazing with 2kg/day of parlour supplementation. The supplementation rate was later reduced to 1kg/day.

Big plans afoot

Along with changing the face of the dairy herd and the production system, Derek will also oversee a major infrastructure development.

Planning permission has been secured for a new milking parlour, extra cubicles, extra feed space and calving and calf-rearing facilities.

Once the new parlour is built, the existing parlour won’t be made redundant. It will be kept in operation to train students and milk any problem cows

“We increased cow numbers last year and converted to a commercial, spring-calving herd, while the facilities on the farm remained static,” Derek explained.

There’s scope to increase further if we want to. But to make it an attractive place to work for staff; to reduce the time spent milking cows; and to provide the best level of training to students, we plan on developing the yard.

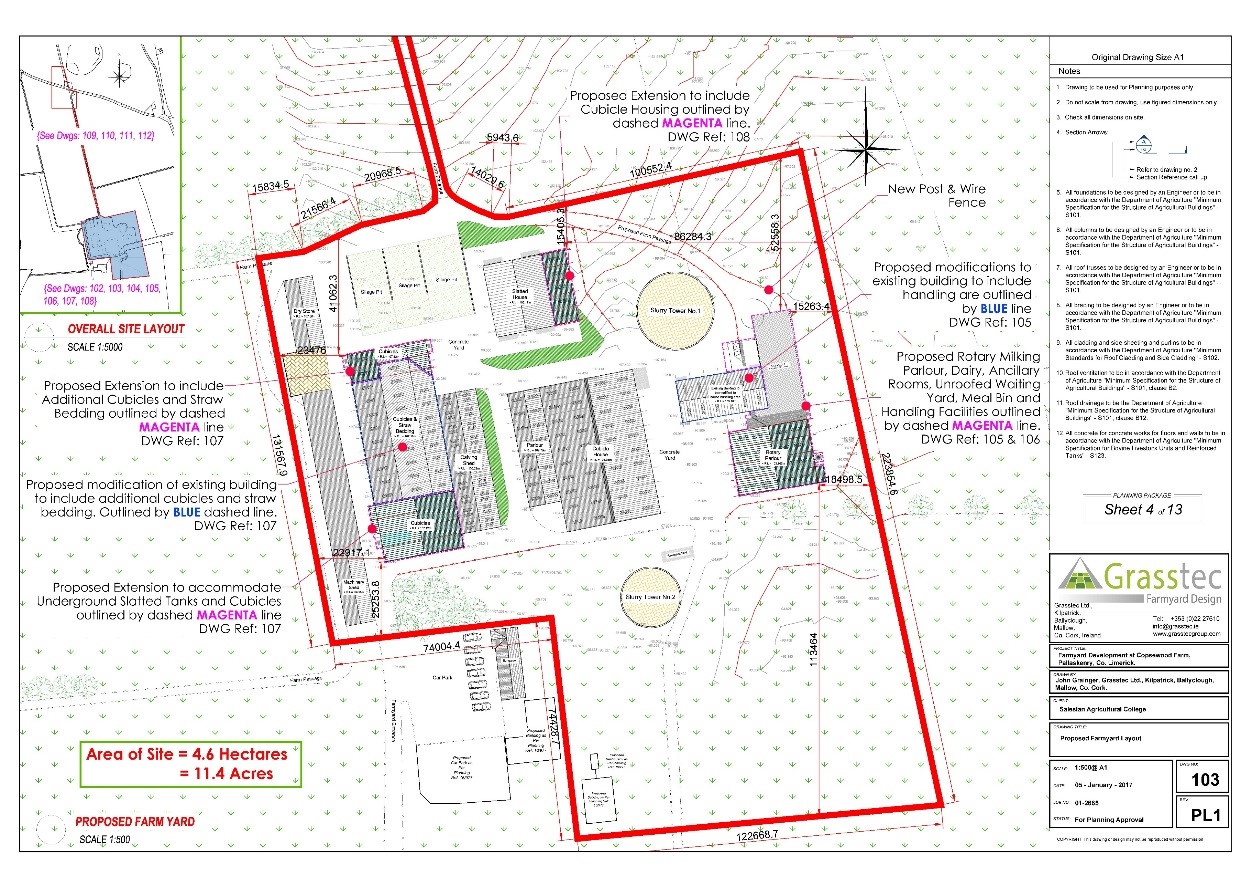

Pallaskenry commissioned Grasstec to review the existing facilities on-farm and prepare various design options of how the farmyard could be improved. Planning has been secured for the project and Derek’s currently securing quotes from various suppliers and builders.

Grasstec’s Simon Hennessy was tasked with planning the project. He explained: “Pallaskenry is at the stage now where they are going to start looking for prices and to see how much it is all going to cost.

“They’ve an idea from the budgets we’ve completed, but it’s to get the final prices now and to see who can do it in the required timeline. The target is to have the project completed in 2019.

Developing the plan

One of the first things Simon completed was a detailed survey of the existing yard. On this, he said: “The yard is set across a few different levels.

“It’s a difficult enough site, so we had to work with what was there as much as possible to make the best use of it and to avoid any costly filling or digging costs where possible.”

After this survey was completed, Simon drew up five different options of how the yard could be developed.

“We looked a how we could extend the existing yard and milking parlour; but it was ruled out quite quickly because cow flow just wouldn’t have been good enough.

“We also looked at a 40-unit herringbone parlour, but that ruled itself out very quickly given the scale of the herd that’s going to be there. A 40-unit herringbone would still take a lot of time to milk and it may not necessarily save on labour, which was what Pallaskenry was looking to do.

“Very quickly we came to the conclusion that we needed to go to an almost greenfield site and look at a rotary parlour.

“We looked at a couple of different locations; but the design we went with utilises the existing calf house as well, which would be slightly redundant when the new calf house at the other side of the yard is fitted out.

“Our key aim in the entire project was to come up with the best layout in terms of cow flow and also to minimise – where possible – the labour that would be required for milking,” Simon noted.

“They were the big things. Pallaskenry is no different than any other commercial farm of a similar size and it needs to have efficient systems for the people using it, working day-to-day. Labour is the big issue and you can’t expect people to be inside a parlour for too long.”

Developing a dairy complex

With the development of the project and plans afoot to install a 50-unit rotary parlour, Pallaskenry will create a complex exhibiting best practice when it comes to training students.

However, Simon stressed that not every dairy farmer who enters Pallaskenry will come under the assumption that they need a rotary parlour at home; the project is also about creating a facility that covers all the bases when it comes to cow flow and farmyard design.

“The important thing for students is to see what good facilities are like and what efficiencies can be gained from them. It’s not all about the rotary parlour. Students may take away some things from the design to improve their farm at home.

It’s not necessary for students to think they need a rotary parlour; but more so for them to take home some of the concepts of the design to improve their farm at home or the farms they’ll be running in the future. “It’s important that all of the different elements are picked up. The Pallaskenry project isn’t just a greenfield project; there’s a lot of retrofitting going on as well and that’s a key thing to show students.

“It’s not just a case of Pallaskenry is going with a greenfield site for the entire project. The plan is trying to make the best use of the facilities that are there, which is a central part of the project,” he said.