Sponsored Article

Benefits of using high-quality silage sheets

Sponsored Article

The success of silage fodder will be determined by the seal, resistance, and flexibility of the silage sheet chosen - which is why choosing high-quality silage sheets is greatly beneficial.

The average amount of waste on a poorly sealed clamp can be up to 8cm on the top and sides, with more than this on the shoulders.

This means waste could cost up to €4.80m2. On a 16mx50m clamp, this could add up to €3,840 in losses.

Rhino Products Ltd. distributes both 400g and 500g silage sheeting. All of Rhino’s silage sheets (covers) are manufactured by Berry Global (BPI), one of the largest plastic companies in the world.

Both sheets are made using the exact same formulae which guarantees quality and also reflects raw material pricing year after year. Therefore, 400g sheets are 20% lighter and 20% cheaper than the 500g sheets.

The quality of Rhino covers is crucial, therefore pricing may be slightly higher than others on the market, but this is due to the high-quality raw materials sourced to make all of the sheets.

High-quality silage sheets

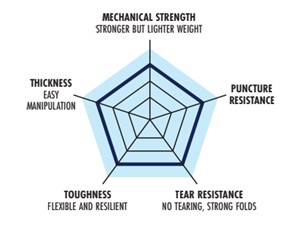

A good silage sheet is recognised by the quality of its high resistance. That’s why Rhino sheets are manufactured using the finest raw materials, including Virgin C8 which is a premium raw material. This ensures that all Rhino sheets are strong, tear and puncture resistant.

Rhino’s sheets also have an advanced polymer blend including the latest seven-layer blown extrusion technology.

The seven-layer manufacturing process allows the most effective placement of raw materials within the film blend so that they reach those parts of the film where they are most needed.

This ensures the UV stabilisers are on the outside of the film to face the weather with the inner layers bearing the high strength and puncture resistance elements of these exceptionally strong silage sheets.

Rhino’s 400g sheets can also be up to 12% heavier than other 400g sheets on the market, which we believe is due to the formulae used and the quality of our sheeting.

Benefits of Rhino sheets at a glance:

- A significantly stronger silage sheet;

- Excellent tear resistance;

- High resistance to weathering and UV inhibitors;

- Easy to apply and longer lasting.

Advice from Rhino

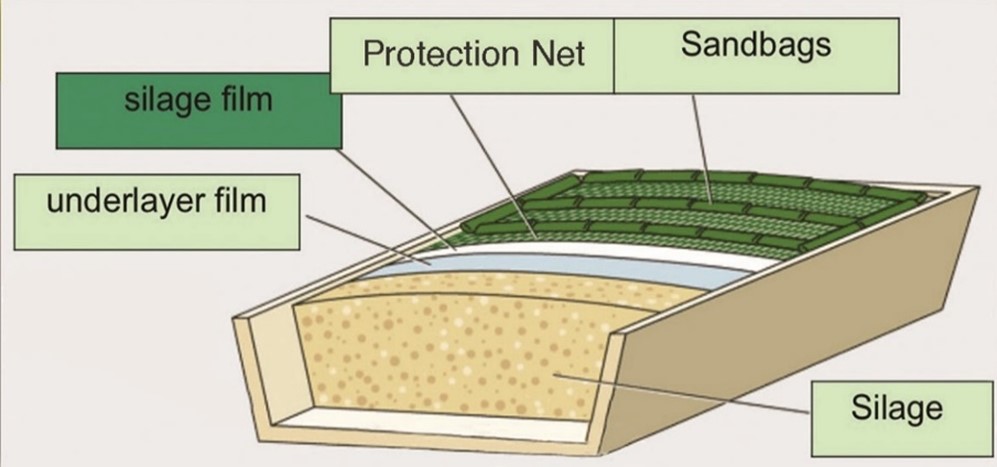

The conclusion from many trials is that a Rhino 400g sheet in conjunction with Clingseal is sufficient for covering any clamp in comparison to any other sheets on the market, including a 500g/600g sheet as the Rhino 400g sheets meet the requirements (weight and quality) to protect your crop.

Rhino’s 400g sheet is also more suitable for covering the clamp as it is not as thick as the 500g/600g sheet which allows it to follow the contours of the pit better.

Clingseal is an additional, thinner, more flexible low-permeability film which is applied to the clamp in order to reduce wastage.

These new generation clamp sheets sit directly beneath the traditional silage sheet where they closely follow and cling to the clamp surface to prevent pockets of trapped air forming which in turn significantly reduces aerobic spoilage.

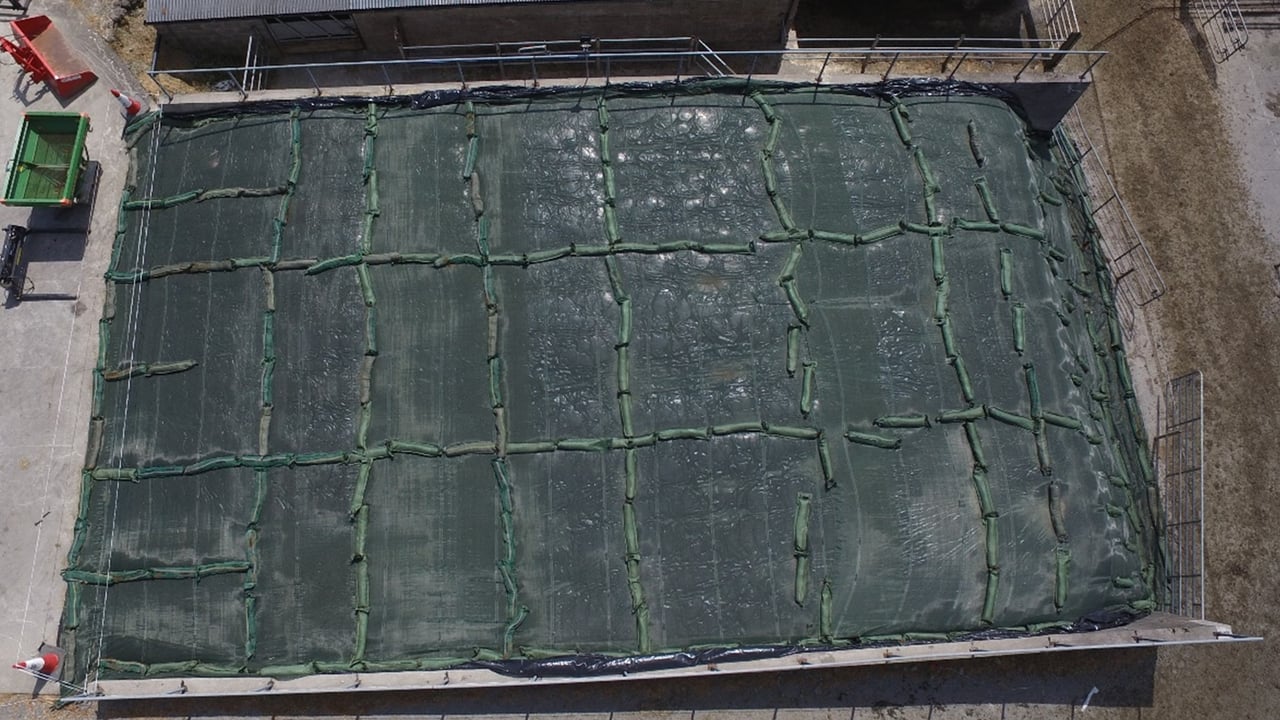

Farmer Adrian Morris used this Rhino-Clingseal approach.

“First of all, we used Rhino sheets across the walls and used the Visqueen Clingseal along the top," he said.

"Clingseal is strong enough to walk on which makes it easier to complete the pit. Then, on top of the Clingseal, we used Rhino’s premium 400g black plastic silage sheet and then Rhino’s green protection net on top of everything.

"Overall, my impression, when we opened our silage pit to show our audience, was that Rhino products was the game-changer for us in terms of silage quality.

"It was responsible for us having such a good pit of silage – one of the best pits of silage we’ve ever had.”

To shop Rhino products, click here.

Sponsored Article