In 2013, Martin Davin’s herd produced 315kg of milk solids; in 2017, 504kg were produced and in 2018, 520kg were. This huge improvement was achieved with a simple grass-based system and moderate meal feeding.

We recently spoke with Martin to get his story.

Martin is farming in Eglish, near Rathdowney, Co. Laois, since 1999 after completing his Green Cert in Rockwell. At that time there were 27 cows going through the parlour filling a 30,000 gallon quota. Plus, at the time, cattle were being finished too and some tillage as well. Eventually, cow numbers climbed up to about 80 pre-end of quota.

Now the farm encompasses 170ac in six different blocks, with a 100ac milking platform split in three sections by public roads. The milking platform is stocked at 3.5LU, with Martin having no plans to grow numbers any further than 130 cows.

Cows are out usually by February 1 (on-off grazing) and come in on November 15, with all cows dried off by December 10; the first milk collection tends to be around February 1. The three “out-farms” comprise of one block of 50ac, 2 miles away and two smaller blocks which are used for silage only.

Pushing on

In 2009, there were two game changing developments for Martin:

- He inherited 40ac, of which 25ac were accessible to the milking herd;

- He joined the O’Moore Discussion Group (facilitated by Fintan Monahan).

“When you’re stood beside a fella in a discussion group and he’s milking the same cows as you, making about €10,000 more than you for doing the same work and the only difference is days-in-milk, because of the six-week calving rate.

“Fair enough, he’s busy for a month. He has half his cows calved in two weeks and you don’t have half calved by Paddy’s Day, but it’s the same work. You just get paid less for it.”

Martin also went on to join the Teagasc Glanbia Monitor Farm Programme (2014) with Richard O’Brien. “The programme taught me to work smart so that I can free up time for jobs which feed into decision making; and to step back and do more planning for the farm.”

L-RL Martin Davin; Fintan Monahan, Teagasc; and Richard O’Brien at the Glanbia/Teagasc joint programme farm walk. Image source: Sandra Hayes, Teagasc

Like with the discussion group, Martin speaks very highly of his fellow farmers. “The lads were just excellent and the programme was very beneficial.”

From 315kg to 520kg of milk solids

On the 2018 co-op report, Martin sold 520kg of milk solids, placing him in the top 4% of Glanbia suppliers, averaging 4.23% fat and 3.51% protein with an SCC of 87, a calving interval of 368 days and an 86% six-week calving rate. All replacements are AI bred.

On the 2017 co-op report, Martin sold 504kg of milk solids (with 40% first and second calvers), placing him in the top 4% of Glanbia suppliers. He averaged 4.26% fat and 3.56% protein with an SCC of 70, a calving interval of 366 days and an 82% six-week calving rate.

Dealing with a fragmented farm and with his driest land across road maximising grass utilisation is a challenge, Martin is looking forward to having an underpass which we improve access to grass and ability to do more on-off grazing.

Looking back on Martin’s 2013 co-op report, which Martin describes as “shocking, just shocking”, Martin sold 315kg of milk solids, giving 11.41L/ He averaged 3.98% fat and 3.26% protein with an SCC of 125 and a calving interval of 374 days.

The 2013 co-op report would have been reflective of the time with quotas, plus Martin dried the cows off in early October to travel to Australia.

In 2018, the average Irish supplier supplied around 400kg of milk solids last year and, looking more internationally, the average supplier in New Zealand supplied 368kg of milk solids in 2018.

Milk recording and selective dry cow therapy

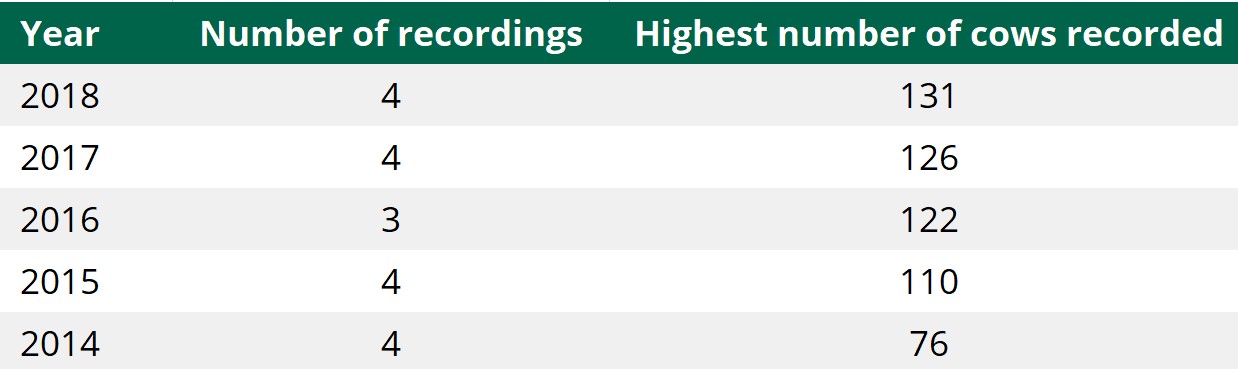

Martin milk records routinely, using Progressive Genetics EDIY Milk Recording Meters provided by Joe Lupton. “In the mid-2000s I had an SCC problem, so I started recording then and that sorted it out, so I stayed at it.”

Selective Dry Cow Therapy (SDCT) has been carried out on-farm for a number of years. For Martin SDCT is working really well: “It’s very good but not easy.”

The criteria SDCT that has been applied to date are any cows with a case of mastitis or SCC over 110,000, receives the full treatment (dry cow and teat seals). Last year, 123 cows were on farm at dry off time, 14 were culled, 50 were treated with dry cow and teat seal and 59 received teat seal only.

For Martin the process of drying the cows is “a surgical job, with three of us here to dry them off.” The team wear double gloves, changing the outer glove every four cows. 24 cows can be dried off in two hours and no more than 24 cows are dried off in one go; to further improve cleanliness tails are clipped before drying day.

Martin was part of the Johnes Phase I programme and he will be part of the Johnes Phase II programme. “For me, Johnes testing is especially important when pooling biestings.”

Breeding

There was no AI in herd till 2009, with mainly Hereford bulls running with cows in the years before that with replacements being bought in. But since AI technician Albert Bailey has come on the scene the Hereford stock bulls haven’t got a look-in.

A few of the first AI bred cows are still on farm, with sires including MTW, BYJ and SOK amongst others. A sire advice is ran via HerdPlus in March or April with AI starting around May 1.

“Ideally, I like to have all calves fairly well reared – or sold – before I start to AI.”

Albert Bailey does the bulk of Martin’s AI. The majority of dairy semen used by Martin is fresh semen (non-frozen), using about 100 fresh high EBI straws a year, and for Martin “it’s a lot easier to get straws off the best bulls fresh”.

Martin also really values the AI service that is provided to him. “If he says he’ll be here at eight o’clock in the morning, you make sure to be finished for eight o’clock in the morning. And that’s the way we work. To be honest, I have great time for Albert.”

Martin uses various Aberdeen Angus sires after dairy AI has been carried out. In the past he has used Belgian Blue and Hereford, but he plans on using more Angus AI going forward. Angus sires used in the last two years include: Christon Elton AA2123; Goulding Man Oh Man AA4087; Lord Hardy KYA; and Marianhill Papa AA4086.

The herd is stocked with cows and heifers sired by: LHZ; DSU; BSH; HMY; MKK; XRB; PBM; TSK; AFD; HYY; WWA; OCP; PKR; HDJ; OMG; ABO; PHC; YAD; LWR; CFF; YAB; FR2079; FR2034; FR2007; and others.

Sires of heifers for bulling this spring include: FR2239; FR2385; FR2079; FR2371; FR4021; FR4020; and others.

Sires of this spring’s calves include: FR2460; FR2239; FR2236; FR2298; LWR; FR2371; and others.

2018

Last year was a year that all involved in farming will remember for a long time. For Martin there were difficulties with snow and drought particularly.

In a standard year, Martin feeds the cows 900kg of meal. Last year, Martin did open 10 bales of silage but when he accessed the situation he realised that he wouldn’t have enough to see him through the winter.

So, he extended the grazing rotation to 50 days and in the end, he fed 1.5t of meal feed and 700kg of soya hulls per cow. Usually, the milking platform grows about 17t grass to the hectare; last year he grew 14t.

Calf rearing

There is a big emphasis put on calf rearing, with Martin’s partner, Lena Sheahan, a vet based in Rathdowney Veterinary Centre helping out on farm – particularly during the busy calving period.

The practice of late night feeding is carried out with the in-calf cows. This means that cows 17/20 will calve during daylight (Oklahoma State University).

Cow 1119 by WWA, Milk Recording Annual Report 2018. She did 612kg milk solids in her second lactation with 301 days in milk, totaling 7,474L at 3.69% protein

“Myself and one of the lads came in the other day for breakfast and when we went out there were four cows after calving; all calves were up and suckling. That’s what I want.”

Peracetic acid normally used as a cluster dip in high SCC situations is used to wash calf buckets, effective in cold water and not harmful. For Martin it has proven to be very effective in terms of disease control (a tip Martin got from Martin Kavanagh, vet).

Martin runs a streamlined ship. By the middle of the year there are just three animal groups, milking cows, in-calf heifers and heifer calves – no deadweight. Cows are culled straight out of the parlour; bull calves, beef calves and excess calves sold as quickly as they can be.

Heifer calves are fed whole milk (5L once a day after three weeks). When you ask Martin why the response is very simple. “It’s a lot easier to tell a fella to put 250L in a milk cart.

Cow 1070 by HYY, on the Milk Recording Annual Report 2018. She did 559kg milk solids in her second lactation and 260 days in milk, totaling 7,326L at 3.47% protein

“Then it is to try mix milk replacer at this or that temperature, try do this, try do that. You have to remember I have different fellas coming and going, so I just go out, point at the milk cart, there is a line in it for 250L, pull the handle when the milk gets to there, feed, simple.”

The calf feeder can fit 50 calves on it. After the first 45 heifer calves, every other calf is sold. The facilities on-farm can handle this and going into the future Martin has no desire to carry anymore heifers or stock in general than he needs. That said he does need to stock the out-farm as not all is suitable for silage cutting. Going forward he reasons that the replacement rate will be 15% or so.

“By only keeping early heifers by default you’ll end up with a fertile herd.” The heifers were weighed recently averaging 342kg. Martin likes to have his heifer calves “well grown”.

I like to do them well as calves, 0.5kg meal all summer, 1kg up to Christmas and then stop. I wouldn’t say they are pushed, just done well.

“Usually, I stomach tube calves when they are dropped but this year, calves are very lively for some reason. I only tubed seven or eight calves this year; year before we tubed them all. Getting in good quality biestings is just so important.

Outsourcing

“All the bigger work is contracted out, allowing us to spend more time with the cows, you’re not worn out spreading fertiliser and slurry.”

Edward Thompson (Thompson & Son Agri Ltd) has been providing contracting services to the Davin’s since 1989.

When it comes to machinery work Martin recommends that farmers “surround yourselves with experts”.

“I only have one tractor, we can only drive one tractor, they [contractors] are the experts. They’re good at cutting silage, making bales and all that stuff, stuff that I am not good at.

“A couple of years ago, I needed to buy a fertiliser spreader. I drove past a tillage farmer [Robert Mansfield] from down the road. I was at school with him. He was going up and down the field – he has GPS the whole lot.

I asked him if he’d be interested, he said yes. He spreads most of the fertiliser, spreading it when it suits, when it’s calm, when fertiliser should be spread – not just when it’s planned to be done or you have the time.

Given the fragmented nature of the farm, Martin does dabble in zero-grazing at the shoulders of the year too.

Staffing

Simplicity and straightforwardness is a big part of Martin’s management style and structure.

A key area for focus, particularly with labour gone so scare, is ease. “You’d be hoping a fella would come and milk for you because you make it easy.”

As part of this there is an automated drafting gate and the cows are fitted out with Heatime collars (and have been since 2007) which makes heat detection really straightforward.

Martin Sutcliffe and Brendan Fitzpatrick, two farmers in their own right whom Martin describes as brilliant, are working on-farm at the moment, at busy times every odd day. Plus they can go home during the day if they need to, flexibility is something Martin likes to offer.

Life needs to be easy, you can make it hard for no benefit, but it is pointless running yourself up and down the road for no gain.

In his double-up milk parlour with 12 units each side, the ACRS insures uniformity of milkings. Milking starts at 7:00am and 3:30pm in the evening, usually finishing up at 5:30pm.

HerdApp

Martin has been linking in with AgriNet for a number of years via its grass measuring software. More recently he has been using HerdApp from AgriNet. “The app itself is brilliant. In fairness Lena is better at it than me at the moment, for registering calves it’s an absolute gift.

“I do need to get more in tune with it, only at it since January but with the dosing and all that, milk recording and everything else, I am looking forward to using it more.”

Martin wouldn’t claim to be a tech wizard, he has found the HerdApp team really helpful when an issue arises.

Conclusion

For Martin a good grazing infrastructure is a necessity and he is genuinely excited about getting the under-pass as it will allow him to utilise more grass, and cuts out having to cross a regional road.

As part of grazing in general; paddocks have multiple gaps, spurs are used, messy gates are avoided and best practice is followed.

Speaking on the future of his herd, Martin wants “130 cows at 550kg”. “My aim is to improve the herd, not increase numbers.”

“My cows got a ferocious amount of feeding last year, but they still pumped it out, even in all the adversity. They have good engines, good capacity and good survival – the cows I have work for me.”

Martin operates a very straightforward system by design, based on his experiences, with all the heavy machinery work outsourced. There are only three cattle groups and not grazing two of the smaller rented blocks amongst other labour reduction actions.

Martin would say that he is not good with technology; however, he certainly doesn’t shy away from technology. He has Heatime, he measures grass, he is using HerdApp, he uses Sire Advice through HerdPlus and more.

These are not complicated systems to use in general, but they all do bring a return on time and/or money invested while reducing hassle. Martin’s primary goal is to maximise return on both the time and money invested in the farm.

“When you’re stood beside a fella making a hape more money than you, why is he doing it? Days in milk, measuring grass, using AI and milk recording. It’s not rocket science. Surround yourself with experts and ask questions. The rewards will come.”