With farm businesses under increasing pressure to become more energy efficient, Teagasc has outlined the key areas where savings can be made – for the benefit of both the environment and the farmer’s pocket.

In a breakdown of where to look, Teagasc specialists John Upton (dairy research officer) and Barry Caslin (Teagasc Rural Economy Development Programme) highlighted that milk cooling, water heating and vacuum pumps account for the biggest proportion of energy use on dairy farms.

It is these areas that offer scope for the greatest savings, the advisors note.

There is a massive range in total energy use – including both electric and fuel usage – across farms.

With profit margins under pressure, there is an urgent need to review all business costs, including electricity and diesel, Teagasc says.

The first step any farmer can take to improve efficiency is to identify the main consumers of electricity, Upton and Caslin noted.

Next ensure that the business is on the best tariff and maximise the use of off-peak electricity.

Basic measures such as using timer switches, lagging pipes (hot and cold) and water tanks, replacing halogen floodlights with sodium lights, and ensuring that equipment such as condensers are clean and well maintained, also make a big difference.

In a breakdown of energy consumption, Teagasc outlined some wide ranges in energy costs, underlining the need to “box clever” when it comes to managing these.

- Average costs are €5 per 1,000L of milk produced – there is large variation in energy costs on dairy farms from €2.60 to €8.70 per 1,000L of milk, or from €1,500 to €4,500 on a 100-cow farm;

- The main drivers of energy consumption on dairy farms are milk cooling (31%), the milking machine (20%), and water heating (23%);

- The average farm could save €1,800 per year through a combination of altered management strategies and energy-efficient technology.

Energy audits are an effective tool to reveal areas where savings can be made, Teagasc says, with the authority’s two officers providing an example of audits below.

The above results were obtained from energy audits carried out on 22 commercial dairy farms over 12 months.

The average herd size was 118 cows, but the study included farms ranging from 47 to 290 cows.

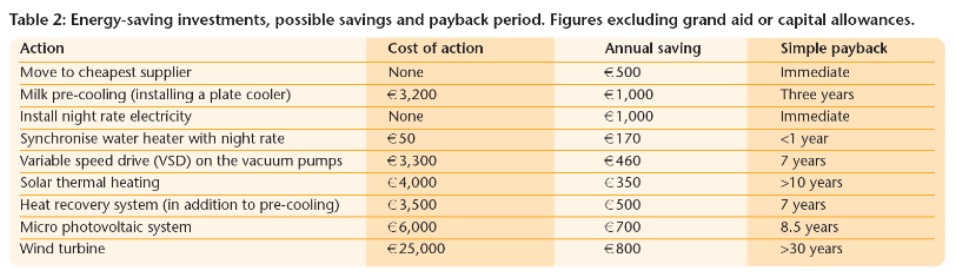

Teagasc also provided an indicator of the approximate payback time for a range of energy-saving actions, as outlined below.

For those interested, more details on these measures can be found on the Teagasc website here.