During the week, Agriland made the trip down south to Co. Cork, to check in on a recently installed 28-unit swing-over milking parlour in Carrignavar.

The new 28-unit parlour is accompanied by a handling area and drafting system, as well as a sizeable collecting yard, and can be found on the farm of father-and-son team, Denis and Thomas Hegarty.

The Cork natives – who supply Clóna Dairy, where their milk is bottled – up until January of this year, were milking their herd of cows through a 12-unit parlour that was installed back in 1993.

However, similar to many other dairy farmers, an increase in cow numbers over the years put considerable pressure on their old parlour and as well, themselves, as much of their time was spent in the parlour.

With Thomas coming behind his father Denis and having a real passion for dairy farming, the decision was made to look at improving the milking facilities on the farm.

Speaking to Agriland about their decision to go ahead and build new milking facilities from scratch, Denis said: “It had come to a point where we had to sit down and discuss what the plan was going to be going forward.

“The main reason why we said we would go ahead and put in the new parlour was because Thomas was passionate about what we do here and wanted to continue on milking cows and take over the mantle from me.

“If he had said to me, I don’t think this life is for me, well then I don’t think we would be standing where we are today in the new parlour.

“Then, other factors such as the time being spent in the old parlour forced us to really consider our options, because between morning and evening milking, we could be seven hours in the parlour.”

Starting from scratch

With no real room to work with where the old parlour was, Denis and Thomas decided to build a new parlour, handling area and collecting yard on a stand-alone site on a paddock close to the main yard.

A good bit of earth had to be taken away to get the site level and during the process, a few snags came up, such as hitting a couple of springs.

However despite this, a level base of which to work with came to fruition eventually, and work then began, putting in the tanks and laying the concrete floors.

This work, including the digging out of the site, was completed by Declan Cunnigham of South East Farm Buildings, while the shed was sourced and erected by O’Dwyer Steel.

All of the electrical work was carried out by Carraig-na-bhFear Electrical Services Ltd., while all the plumbing was carried out by Southern Pumps LTD.

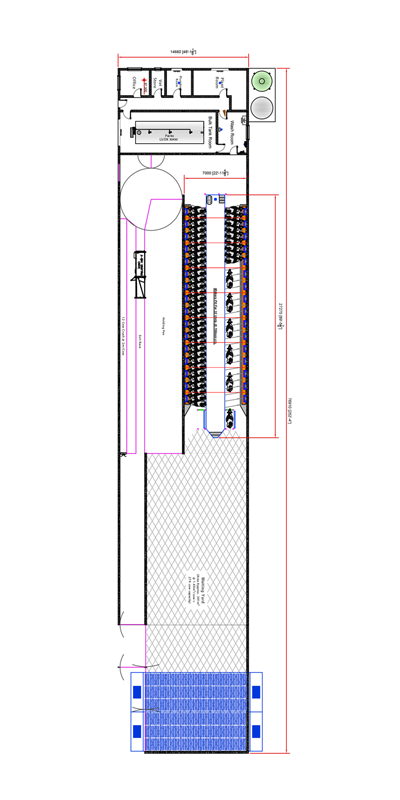

A detailed drawing of the newly-built dairy can be seen below. It was drawn up by James O’Callaghan of Farm Design Solutions.

The hub of the new build: the parlour

The focal point of the new build is of course, the new 28-unit swing-over parlour.

Having already had a 12-unit Boumatic Gascoigne Melotte parlour and having been very happy with it, they decided to go back again and install a 28-unit Boumatic Gascoigne Melotte Swing-Over parlour.

The new parlour, which was commissioned in January of this year, comes nearly fully equipped with the exception of a cluster flush system – something the Hegartys said they could do without as the somatic cell count (SCC) of the herd is quite good.

The 28-unit milking machine and drafting system were sourced from Richard Kingston of Boumatic Gascoigne Mellote, while the parlour was fitted by Sean Coleman Dairy Services.

The spec of the 28-unit swing-over milking parlour – which is also hooked up to the drafting system – includes:

- Sequential bailing;

- Touchpoint ICAR approved milk meter with automatic cluster removers built-in;

- Smart dairy herd management system for auto-ID, feed to yield and drafting;

- 2-way drafting gate;

- Lightweight clusters;

- Cashman electronic feeders and auger;

- Air Star variable speed vacuum pump;

- Dumpline plug-in system.

Speaking about how they find milking in the new parlour, Denis and Thomas said: “It’s a lovely bright environment to work in first and foremost. The old parlour had a low roof and it was much darker inside.

“The parlour itself is of a high spec. Like I said at the start, milking time in the old parlour was killing us and that was a big factor in our decision to put in a new parlour.

“It was taking the guts of three and a half hours to milk the cows in the old parlour both morning and evening, whereas now, with two of us in the pit, it takes us about an hour and ten minutes to solely milk the cows – you could add another half an hour for washing up then after.”

“Even just the small things such as the difference in weight of the clusters between the old and new parlour and the joy of having ACR’s, just makes the whole milking process a much easier task,” they added.

Thomas then said that the great thing about the new machine is that it won’t let you make any mistakes – which would have been easier to make in the old parlour.

He explained: “The fact the machine won’t let you make a mistake is a great thing and if you do, it’s your fault,” he joked.

“For example, if a cow is on a course of antibiotics, it will come up on the touchpad in the parlour and it will ask you to press OK if you’re happy to continue.

“For us here, we are seeing the cows twice a day and know what cows are on antibiotics [they are marked anyway] and know what ones milk isn’t going into the bulk tank.

“But for someone who is coming in at the weekend to do a bit of relief milking, it’s great that facility is there to tell whoever is milking the cows, that this cow isn’t going into the bulk tank – it adds that extra layer of protection really to prevent something going wrong.

“And for cows that aren’t going into the bulk tank, the plug-in dumpline is there and is very good and simple to use.”

Touching on the sequential bailing, Denis said: “It’s a great job in that it gives you great control over the cows and helps to keep the flow of cows going through the parlour going nicely and avoids cows from looping their head into another cow’s trough.”

Lastly, Thomas said the information you get back from the machine about your cows is great and helps to make better decisions, for example, on what cows should be getting more ration in the parlour and also being able to draft cows at ease from the comforts of the pit.

He added: “The information we get from the machine is of huge benefit to us. For example, we had batch feeders in the old parlour and obviously, all the cows were getting the same amount of meal.

“Whereas now, with the feed-to-yield system, we can reward the cows that are performing best with more meal and cut back on other cows. In time we should hopefully see our meal bill getting that bit smaller.

“As well as that, the ease of being able to draft away cows while standing in the pit or by sitting down at the computer prior to milking and type in the tag numbers of cows we want to hold back is great. I can even do it from my phone if I want to.”

Everything else around the parlour

To the front of the building an office, plant room and the bulk tank room can be found.

The Hegartys opted to install an 18,000L bulk tank and a 22t meal bin.

Beyond where the bulk tank is obviously where the milking parlour lies, but directly opposite the parlour, an exit race, drafting system, penning area and crush can be found.

The gates for the crush and penning area were erected by TSM Limited.

Once cows exit the parlour, they make their way down the exit race, back out to pasture.

A Boumatic Gascoigne Melotte drafting system was also installed – which is linked up to the parlour.

A collecting yard that can hold in excess of 300 cows was also built – so as to accommodate further expansion for the Hegartys if they so wish.

Having experienced cows ‘doing the splits’ in their old collecting yard, Denis and Thomas made sure that the concrete was grooved in the new collecting yard, having lost some “great cows” in times gone by.

Slatted tanks can be found at the rear of the shed for faeces and washings from the parlour, and hoses to be washed down into after milking.

Cost

The fact that Denis and Thomas are in partnership together, meant they decided to apply for a grant which would see them eligible to claim up to €180,000 under the Targeted Agricultural Modernisation Scheme (TAMS II).

Having been improved, this helped to bring down the overall cost of the new project. So when the value of the grant is taken off the overall cost, the new build is standing to the Hegartys at roughly €1,500 per cow.

Looking back on their decision to go ahead and put in a new milking parlour, Denis said: “It’s a huge improvement on what we had and we have settled into it quite well.

“Obviously, the big plus of it is the time we are saving being in the parlour. Another big plus for the both of us is that we can now get in help much easier now.

“With the old parlour, is was near impossible to get outside help in to milk the cows, to get a break away from it.

“Now with the new parlour, that problem no longer exists. The cows have taken to it quite well and are well and truly settled into it now.

“It’s was a big decision to make but we are happy we went and did it, because now we are not only making life that bit easier for ourselves, but there is a modern parlour here for years to come to enjoy working in,” Denis concluded.