Vogelsang factory brings expertise and precision to slurry management

If thought of at all, Vogelsang was, for many years, considered a rather obscure manufacturer of macerators that existed somewhere over there on the continent and little more was known of the company.

However, over the last couple of years it has been addressing this situation for two prominent reasons, the first being that the competition for macerators has been heating up in Ireland as local companies brought their own units to the market and, secondly, it has a good deal more to offer farmers and contractors.

The size of the company may come as a surprise to many, for at its base in northern Germany it employs 930 staff in research, production and administration. It has another factory in Spain and 26 sales subsidiaries around the world, including Ireland.

Forestry products

It was formed in 1927 by Hugo Vogelsang and was originally a saw mill producing barrels which led to mechanical components being added to create such products as clothes washers.

Early on slurry tankers were also produced and the company has been in this business ever since, producing its first rubber lobed pump in 1970 and the first ever dribble bar in 1980.

The past has not been without its difficulties and the company was, for many years ran by Maria Vogelsang when her husband, and the son of the founder, Helmut Vogelsang passed away.

She saw it through this tough time and it now prospers under the leadership of her sons, Hugo and Harald, who, in turn, are bringing the next generation into the business.

Traditional values

It is then the archetypal German family firm and that is how it intends to remain, with the usual focus on research and development which characterises so many successful German family firms.

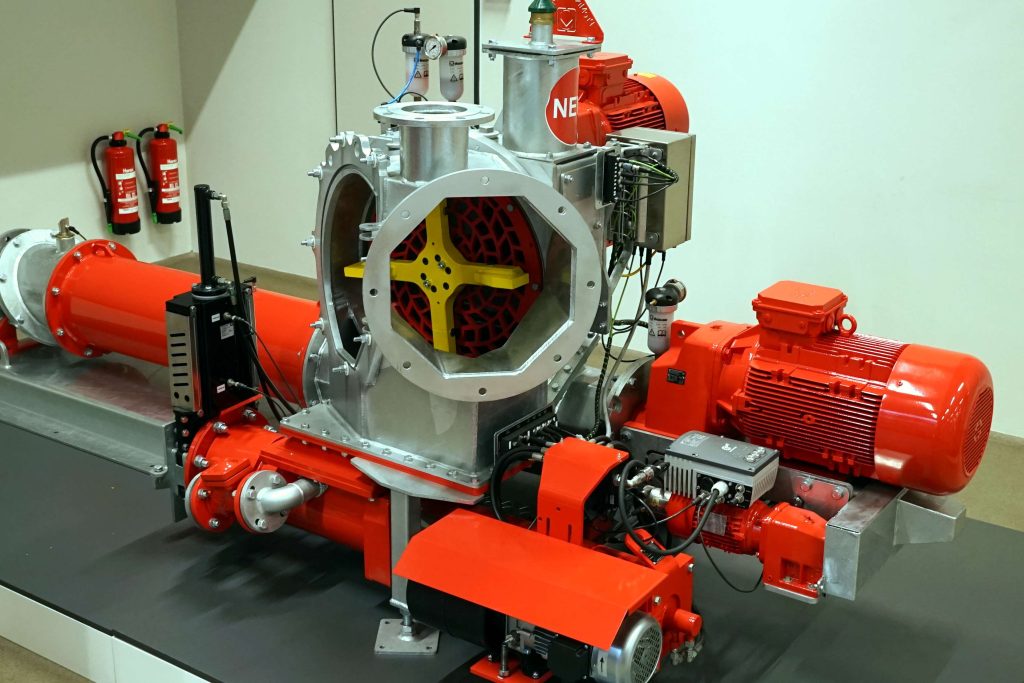

This then is an organization to be reckoned with in its field, and that field is the handling and management of slurries and liquid wastes, whether they be industrial or agricultural.

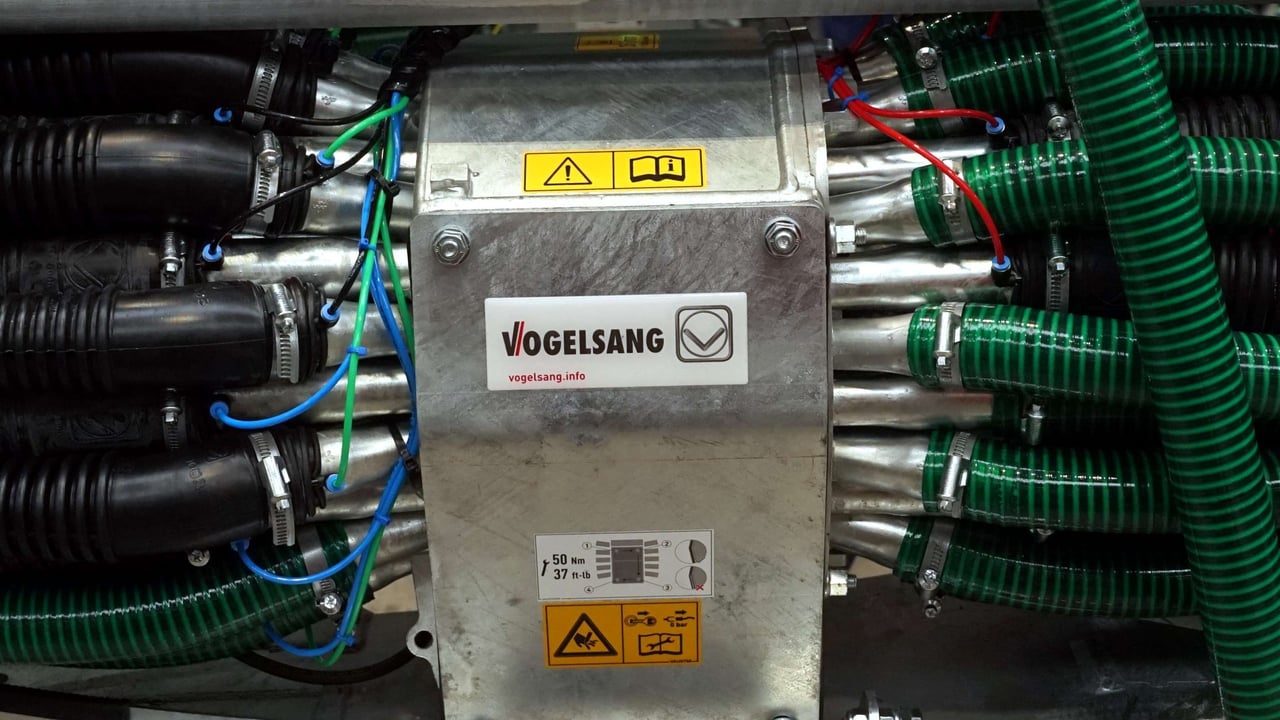

Yet, purely from an engineering point of view, the factory considers itself predominantly a milling specialist for the castings and inner workings of the pumps. Macerators and other items of processing equipment require a precise degree of finish, mainly by the milling of the faces of castings.

The items produced rely heavily on seals, joints and components that match exactly in size and shape, and the long lines of milling machines within the production facilities show that they are well equipped to produce them.

There is also a high degree of automation where possible, but while we are so often treated to images of robots assembling cars and other high volume goods, the relatively low number of individual components at Vogelsang does not always lend itself to machine assembly.

This is exemplified by the assembly of shaft seals which requires a consistent touch and lends itself to the constant attention of a robot, whilst welding, on the other hand, is much more an involved craft and is still mostly left to humans.

Booms just get bigger

Vogelsang has also moved into boom production over the years and the basic frames are made in its other German factory. These are then galvanised and shipped to Oldenburg for assembly and fitting out.

The bigger the boom the greater the amount of engineering that has go into into it and with the larger units Vogelsang insists on sending one of its own technicians to fit them to tankers made by third parties.

It is only by doing so that it can guarantee the booms to work properly, for there have been cases where original equipment manufacturers (OEMs) have made modifications to the units, or fitted them incorrectly, resulting in them failing in the field and Vogelsang getting the blame.

Presently, the widest boom produced is 36m but the company has recently received a request for 48m.

Looking forward the company believes that there is long future for its products and demand can only increase. It certainly intends on establishing itself as a supplier to farmers through manufacturers and retailers such as Atkins, thus moving away from selling directly to the end user.