Soil fertility is certainly top of both farmers and policy makers minds currently, with a broad consensus that it plays a key role in the continued economic and environmental sustainability of Irish farms.

Building and maintaining soil fertility on most Irish farms is achieved through the application of multi-nutrient fertilisers – nitrogen (N), phosphorus (P), and potassium (K) or NPKs.

They need to spread evenly, but how many examine if the fertiliser they’ve purchased is up to the job?

NPK fertilisers are very convenient and allow us to apply the necessary nutrients in one application, on grassland and tillage crops.

The physical quality of these NPK’s, together with the performance of the fertiliser spreader, will govern how evenly the individual nutrients are distributed across any field.

Although blended fertilisers make up the majority of the NPK market, a growing appreciation of consistent fertiliser quality by farmers has led to an increasing demand for YaraMila Complex Compound Fertilisers (CCF).

YaraMila is the brand name for Yara’s NPK product range. The word ‘Mila’ – meaning success in old Norse. If the product name is preceded by ‘YaraMila’, it’s guaranteed a ‘Complex Compound Fertiliser’ (CCF) produced in one of Yara’s European plants.

Irish farmers were well accustomed to CCF fertilisers up to 20 years ago, with Irish Fertiliser Industries (IFI’s) plant in Belfast producing about 500,000t annually for the Irish market.

What differentiates a YaraMila product from a typical NPK blend?

It all boils down to their physical quality and composition. Each granule has the same physical characteristics, the spread pattern is more predictable and this leads to more accurate spreading.

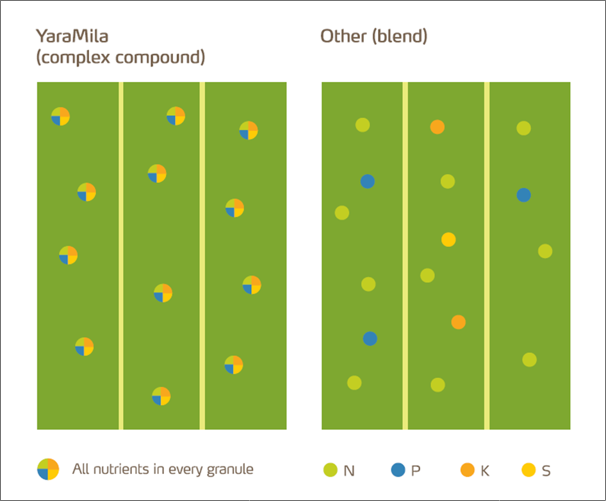

The composition of these products results in more landing sites for each nutrient, as each granule contains the nutrient analysis for that product.

For example, we know phosphorus isn’t a very mobile nutrient in the soil, so the phosphorus we apply in fertiliser needs to be well distributed.

A YaraMila grassland grade will have ten times more phosphorus landing sites than an equivalent blended product.

The effects of uneven nutrient applications remain invisible in most cases. Only drastic variations are visible as dark and light stripes with unevenly applied nitrogen or sulphur.

However, losses set in long before any variation becomes visible to the naked eye. The cost of poor fertiliser quality is mainly due to lost yield and lost quality in the year of application, however the effects of phosphorus and potassium on soil fertility are more subtle and longer term.

A study (Horrell et al., 1999.) in New Zealand calculated that on dairy farms after a five year period, the annual economic loss of unevenly applied phosphorus and sulphur was NZ$401/ha.

Accurate spreading is determined by calculating the co-efficient of variation (CV) using a tray test for a given fertiliser and spreader. A CV of less than 15% is acceptable, but it should preferably be less than 10%.

Spreading fertiliser with CV of greater than 15% will impact crop performance and soil fertility. The CV for a CCF product is a true measure of how even each nutrient is being spread.

For a blend, a low CV may indicate a good overall spread pattern but it can mask high CV’s for individual nutrients.

- Bulk density – weight (kgs) of fertiliser for a given volume (L), the higher the bulk density the better. The analogy of a table tennis ball and a golf ball is often used to explain why bulk density is an important measure of fertiliser quality. They’re both the same size, but you can throw a golf ball further. YaraMila products have a high bulk density (~1.0 kg/L);

- Size – measured as the diameter (mm) of the fertiliser particles. For identical bulk density, bigger particles can be thrown further as they’re heavier. 80% of the product should have a size range of 3.3-4.75 mm. Quality control at Yara plants ensures under and over-sized particles are screened out before shipping;

- Shape – The more the fertiliser particles are perfectly rounded and smooth, the better the aerodynamics and spreading trajectory. YaraMila products are spherical in shape, which allows for more accurate spreading;

- Hardness – The harder the granules, the less likely they crush during handling and under the impact of spreader vanes;

- Crushed granules create unwanted dust and creates an unpredictable spread pattern. YaraMila granules can withstand at least 3kg (30N) in force.

Soil fertility is certainly an investment, and often considerable effort is made to soil test and then using these results to put a nutrient plan in place.

The next steps of purchasing the fertiliser and spreading it evenly, are as important as the previous steps, but on many farms little thought is given to the quality of the inputs and spreading them evenly.

The cost alone merits dedicating time to ensure that the nutrients you’ve purchased are precisely applied.

For more information on NPKs click here