Advances in fertiliser spreading highlighted at Agritechnica 2025

The recently held Agritechnica preview event had several manufacturers offering new ways to make applications of fertiliser more efficient and effective.

Applying fertiliser has moved on a good deal from the oscillating spout-type spreader, with even Vicon having now discontinued with the majority of spreaders now relying on spinning discs.

Amazone has long championed this method, and the company's more recent efforts in perfecting the technique has been rewarded by the DLG in the form of two silver medals.

Fertiliser woes

Fertiliser is an unpredictable material, as samples for a product of the same analysis may be inconsistent, even from bag to bag.

To help overcome this problem, the company has developed a system which automatically adjusts the spreader by constant monitoring of the spread pattern.

Known as AutoSpread, the system analyses the direction of throw and throwing distance to work out the spread pattern and adjusts the spreader in real time to ensure consistent coverage.

Blend recognition

For those who already have an Amazone machine, there is also the EasyMatch app which identifies fertiliser through a camera image and recommends the ideal settings.

A reference frame is provided to place on the sample, which the app's algorithms uses to compare the image with a comprehensive fertiliser database and provides the correct settings for Amazone spreaders.

It can also recommend settings for materials that are not in the database.

Sky Agriculture were also awarded a silver medal for a similar development called FertiEye.

This method combines a sample preparation system with image analysis, separating individual granules to identify their colour and geometry, this data is then used to calculate particle size and flight characteristics.

The third dimension

Duxalpha is another silver medal winner at Agritechnica which may further enhance fertiliser spreading accuracy through the setting of tramlines in 3D.

Tramline setting does not usually take into account the topography of the land - hills and dips are basically ignored in the two-dimensional maps used by existing systems.

By taking into account the shape of the land, the Duxalpha helps to avoid gaps and overlaps on hilly terrain and thereby supports precise precise placement of inputs such as fertiliser.

Precise boundary placement

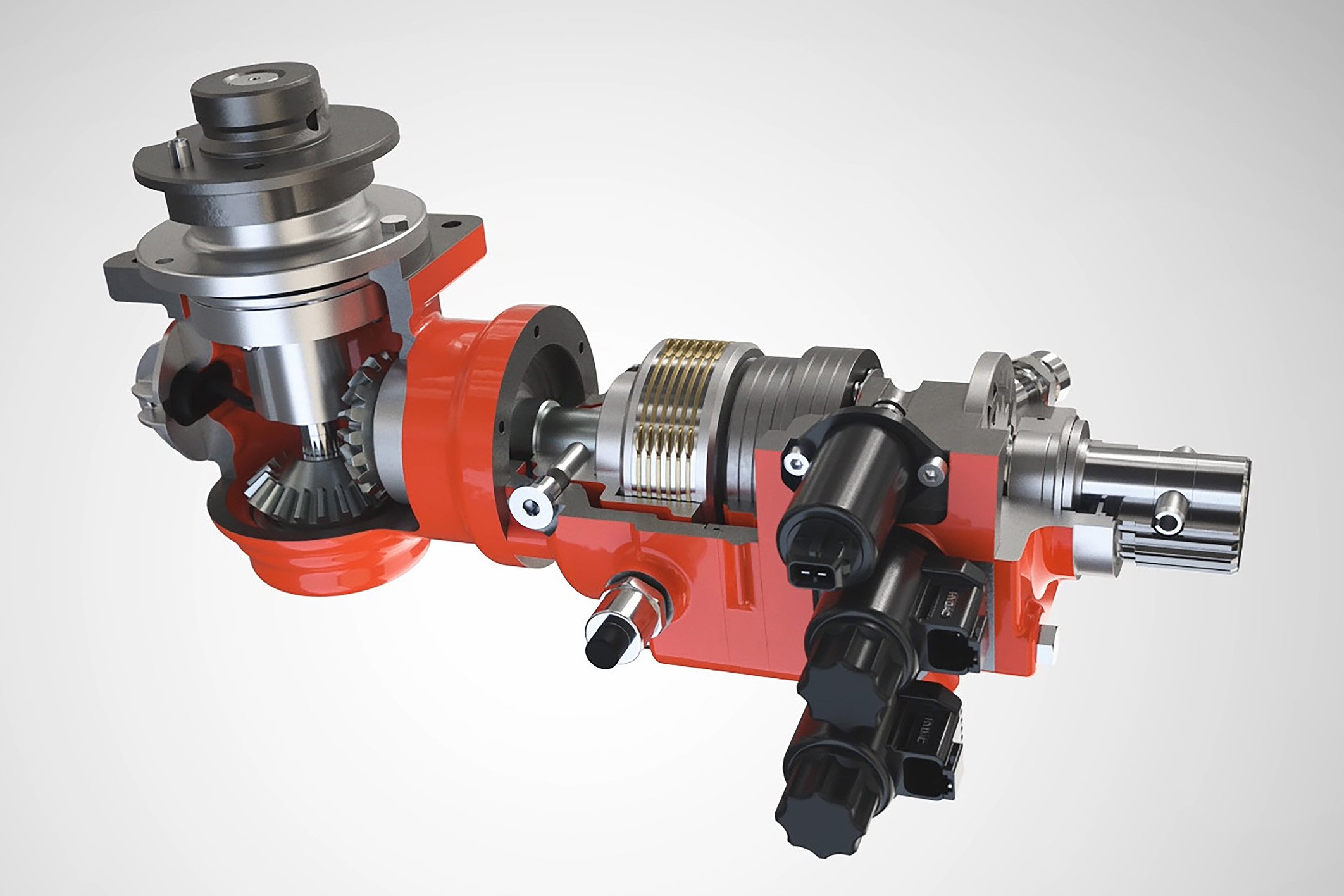

Adjusting the spreading pattern between the discs on twin disc spreaders, powered by mechanical power take-off (PTO), has not been possible up until now, claims the manufacturer Rauch.

To overcome this, the company has developed the VarioSmart system which allows the disc speed to differ, thus enabling more precise placement of the product alongside field boundaries and water courses.

While the left-hand disc remains at a constant speed, the disc on the right can be infinitely varied from 900-400rpm from the tractor cab.