Pottinger brings digitally enhanced drill to Carlow demo day

The Terrasem V6000 is not a new drill from Pottinger: in its latest standard guise it was introduced in 2023, but this year the company has brought to the market a version that integrates itself with a tractor's ISOBUS capabilities to a far greater extent.

In the V6000 DZ, the company has used the ISOBUS platform to enhance the operation and efficiency of the drill, enabling greater control of machine and more accurate placement of seed and fertiliser, especially at the headlands.

It is in this latter feature where the company claims the greatest efficiencies are made, for the coulters come with section control in metre-widths.

Precise placement

Section control on sprayers is well established but, by extending this feature to drills, Pottinger has enabled the saving of seed and fertiliser at the headlands through the process differential closure of the coulters as the tractor passes across the boundary line set by the satellite navigation system.

This, however, is only part of what has been added to the drill, for it also offers sequential lifting and re-engagement of its various elements at the headlands.

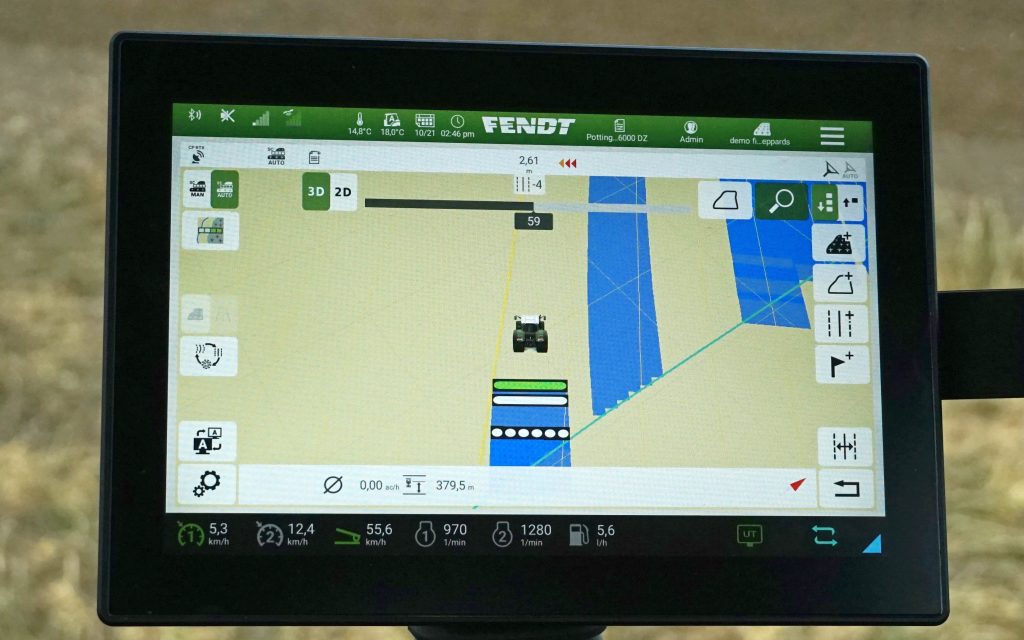

To make sense of it all in the cab, Pottinger uses what it dubs a boom control system.

To help understand how this works, it is worth taking a look at the Terrasem drill itself, which is very much designed as a hard-wearing machine for big areas and tight windows.

One of the first issues that Pottinger has had to address is to make it as auto-steer friendly as possible.

This has been achieved by ensuring both halves are exactly the same, with the opposing disc banks cancelling out the lateral forces they impose on the frame.

This symmetry avoids the issue of it pulling to one side, which can introduce errors into the steering and navigation.

Screens and booms

In its standard form, the drill has four basic functions: cultivation; levelling; reconsolidation; and finally drilling, with light tines to cover the seed at its very tail.

Within the ISOBUS system developed by Pottinger, these four sections of the drill are referred to as booms, the discs being one boom, the levelling boards another, and so on.

Each boom can be controlled from the ISOBUS screen in terms of disc depth, levelling board angle, and so on.

They can also be raised or lowered sequentially, according to the position of the tractor in relation to the set boundary.

By doing so, the drill is either lifted or lowered into work one boom at a time rather than have the entire drill lifted as a whole when it gets to the headland.

Seed saving with no gaps

The coulter boom itself is separated into six sections. As each section crosses the line, the coulters within it are switched off to prevent double-seeding of the headland area.

This is where seed, fertiliser, and money can be saved, though by how much will depend on field size and irregularity.

It is an unfortunate paradox that the farmer with smaller fields, who is likely to gain most from it, is less likely to be using a drill of this size and expense.

The system works by knowing the distance from the tractor of each boom. By this, it can judge when to raise or lower the feature it controls.

For best effect, the tractor needs to be kept at a constant speed as it enters the headland area, thus requiring the operator to decelerate either before the headland or wait until on it.

This suggests that, for best effect, the drill needs to be attached to a tractor with a constantly variable transmission (CVT), which is likely to give greater consistency in speed at this critical moment.

Irish conditions

The machine being demonstrated at the event had been in Ireland for the summer, where it was not only being shown to potential customers but was also testing the concept of split fertiliser application.

The idea being examined is as to whether there is any advantage to spitting the fertiliser application on the machine.

To do so, a portion of the fertiliser is being fed from the tank down to air spreader-type plates situated immediately behind the discs and in front of the levelling boards.

The effect is to broadcast and incorporate the granules into the soil profile rather than concentrate it in an area immediately adjacent to the seed.

The ratio of broadcast to placed fertiliser can be varied to suit whatever target is to be met, but as yet no conclusions have been drawn or decisions made as to whether it will become available as a standard option.

Tractor and implement as one

Altogether, the new Pottinger V600 DZ marks a significant milestone in the development of not just drilling, but also the application of digital technology to regular farming operations.

It is the tractor manufacturers who have been encouraging the use of electronics on the vehicles, introducing new ways for farmers to operate machinery.

But now it is the implement-makers who are taking the lead and dictating what they want from the tractor, be it through tractor implement management or, in the case of Pottinger, introducing its own software to make use of a tractor's capabilities.

There is nothing particularly new about this of course, but along with the symmetric frame, pressure-sensing hydraulics, and preference for a CVT-equipped tractor, the new drill is a solid step towards efficient integration of the two halves of the tractor - implement equation.