This week’s Buildings Focus saw Agriland make the trip to Co. Cavan, to check out a grant-spec sheep shed on the farm of David Beattie, just outside Ballinagh.

The Cavan-native runs a flock of 300 purebred Lleyn sheep on 120ac of mixed ground.

Up until 2019, David was lambing both indoors and outdoors, as he only had accommodation for up to 120 ewes, and with the rapid expansion of his flock over the last few years, he needed to look at building new housing accommodation to facilitate the increase.

Speaking to Agriland during the week about his decision to build a new sheep unit and what life was like before it was built, David said: “I could only fit 120 ewes in my old lambing shed at a time and with the numbers I am at now, it wasn’t really sustainable.

“The fact that there was a grant available there, I said to myself that I’ll put an application in and because I could have been eligible for a 60% grant, I felt I couldn’t turn down the opportunity if I was approved – and thankfully I was.

“Lambing some of the ewes outdoors was fine, but it’s hard to beat having a shed to house all of your ewes just for peace of mind, and also just to be able to manage them that bit more easily and to be able to keep a closer eye on them.”

Design of sheep unit

Due to his line of work outside of the farm, David was able to complete the bulk of the work himself. He also designed the shed himself.

He sourced all the steel and erected the shed himself, while a local contractor came in to dig out the site for him.

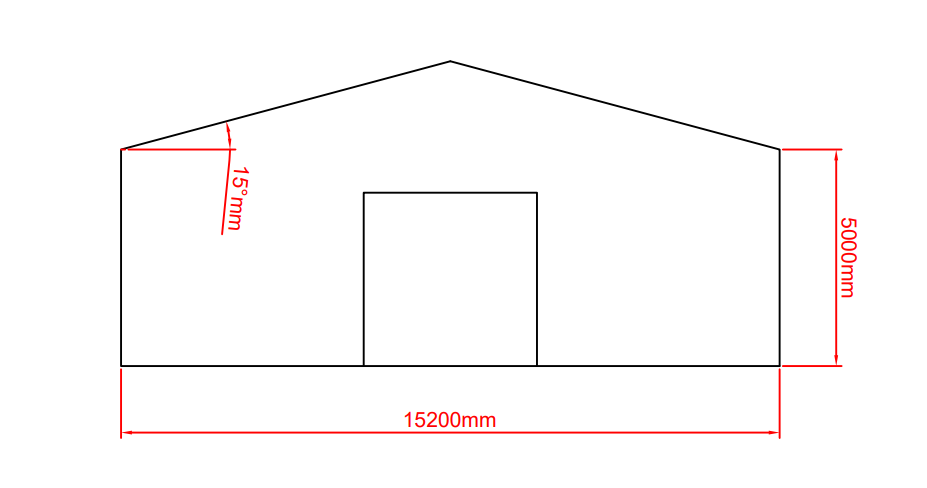

Looking at the layout of the shed in more detail, the unit is 15.2m wide and 28.5m long.

The unit stands 5m to the eave gutters. There are eight pens served with a centre passageway that runs the length of the unit.

The feeding passegway is 4m wide. Each of the pens are 6.375m long and 5.6m wide. In between each passageway are walkways for meal feeding – which are 0.6m wide.

From start to finish, the build took nine months to complete.

Looking inside the unit

To hold 300 ewes in a shed, a lot of thought is needed when designing, and that’s exactly what David did.

Having lambed 120 ewes previously in a small, tight shed, he wanted a shed with a little more breathing space, and one that could be altered to suit different jobs.

As you first walk into the shed, the one element of it that catches your breath is the sheer size of it. When constructing a shed for 300 sheep, adequate space and ventilation is critically important – which David stressed was something he wanted to ensure was right.

He said: “I worked in a tighter shed before this, with a low pitched roof in comparison to what I have now – so I wanted to move away from that.

“When the shed is full of sheep and the doors are closed, you definitely need the shed as big as it is.

“To help circulate airflow throughout the shed, I went with vented sheeting. Clear roof lights were fitted and help to brighten up the shed significantly, and make it a nicer and brighter environment to work in.

“Instead of going with sliding doors, I opted to go with two roller doors at either end of the feeding passageway. When you boil it down, the cost difference between the two is very small, and just with a push of the button you can open and close them in an instant.

“The roller doors at either end of the shed help to increase airflow throughout the shed and make a huge difference when all the ewes are housed together at first, until they gradually lamb and head back out again.”

Another aspect of the unit that David put a lot of thought into was the way the pens are set up.

He added: “One of the big pluses about the shed is the way the penning is laid out. All of the walkthrough feeders can be hinged back against the wall.

“So then basically I’m left with one big, long pen on either side of the main feeding passageway, which not only means I can fit more sheep, but it just makes it easy to bring the sheep in and not having to be splitting them up into the various pens.”

At lambing time, David reverts back to using the eight pens and splits up his ewes based on how many lambs they are carrying. To ensure he had plenty of feed space, particularly concentrate feeding space, he incorporated walkthrough feeders in between the pens.

When lambing begins, individual pens are set up along the feed passgeway and in a shed next door to the new one, which can be accessed through one of the small doors at the side of the unit.

Looking at other features of the lambing, the bottom half of the walkthrough feed barriers are covered in mesh, which is extremely useful at lambing time to stop lambs from going from one pen to another and getting mixed up.

In each of the pens is a power source – for an infrared lamp for example, or for shearing time, for the shearer to plug in his shears and be able to move around and go from pen to pen if he so wishes.

At the front of each pen, facing the feeding passageway, is a small gate that allows David access into each of the eight large group pens.

David made all of the feed barriers and gates in the shed himself.

At the front of the build, is a washing area and storage area for all the essentials needed at lambing time.

Two small doorways are located at the side of the shed, leading out to the old lean-to and new storage shed.

Dead in the middle of the unit, near the roof, is a camera, which David said was one of the best investments he has made on the farm to date – and even though it is only in use for a short period, it is “invaluable to him”.

David said the only thing that is off-standard about the new build is the walls of the shed – where he used wall panels rather than standard shuttered walls.

He said the reason for this is that if he ever wanted to extend the shed, he could move the walls out.

Cost

As mentioned already, David was able to avail of the Targeted Agricultural Modernisation Scheme (TAMS II) – which meant he was eligible for a 60% grant.

The fact he was able to basically do everything from start to finish meant he was able to keep costs down.

The total cost of the build came to €79,000 plus VAT. However, when the value of the grant is taken off and the VAT reclaimed, the cost of the shed, out of David’s own pocket, is standing to him at €37,000.

Speaking about his decision to build the new shed and how it is working out for him so far, he said: “It was a really good decision looking back on it now to go ahead and go for it.

“I used to lamb outdoors and found it fine, but when the weather comes rough and you need to have your ewes inside, it just gives you peace of mind that you have somewhere to house them all – and it makes lambing time that bit easier to manage.

“The fact the grant was there made it worthwhile, otherwise, it would have been a harder decision to make.

“The fact I could put up the shed myself helped to keep the cost down. I’m just after finishing my second lambing season in it and it’s a joy to work in.

“I’m glad I put it up when I did – which was two years ago now – just with the way the cost of building materials have gone recently.

“I’d say if I was to build it now, you could be talking about it costing up on €120,000. The fact that sheep prices are going strong as well, gives you more confidence that you made the right decision and so far I think I have,” David concluded.