The third new build in our ‘Back In Focus’ series is a 96-cubicle shed on the farm of Sebana Moynagh, in Co. Cavan.

Sebana, who farms full-time, currently runs a herd of 80 pedigree Charolais cows and their calves, along with 20 replacement heifers.

Since 2015, cow numbers on the farm have doubled going from 40 to 80 head, which had put pressure on the housing facilities that were in place.

Also Read: Buildings focus: Housing 60 head of suckler cows in a new cubicle shed in Co. KildareSpeaking to AgriLand, Sebana explained: “Prior to the new cubicle shed, I had a slatted shed and a creep area that could hold about 30 cows and their calves.”

She added: “I also outwintered some of the stock, so – in truth – we had no choice but to build a new housing facility, especially as cow numbers were increasing year-on-year.

“Cow comfort was also a big factor in my decision to install a cubicle shed rather than another slatted house. I find the cows are much happier lying on the cubicles, especially if they are fitted with mats.”

‘Staying local’

The entire build was carried out by contractors from the local area, according to Sebana.

The new cubicle shed was built on a greenfield site located beside the main farmyard. The shed was constructed on good-quality ground, so no issues arose when it came to digging out the site.

The excavation work was carried out by a local contractor – namely Nobby Kenny. The concrete work was completed by Sean Smyth of SS Shuttering.

The shed was designed by both Sebana and Stephen Farrelly of Rossdrum Engineering.

Speaking about the build, Stephen Farrelly of Rossdrum Engineering said: “It was a straightforward project. I suppose what made the job that little bit easier was that everyone involved in the building of the unit was local and knew each other well.

This made life easier in terms of meeting deadlines and trying to get certain parts of the job completed, so that we could move onto the next phase as quickly as possible.

“There is nothing more frustrating than having to wait for a contractor to come to do a job on a build and have to wait for him to finish it before you can move onto the next stage. Thankfully, for once, it was the complete opposite for this job.

“The only issue was the weather, which delayed the completion of the job for quite a while; however, in spite of this, everything else went to plan.”

Design

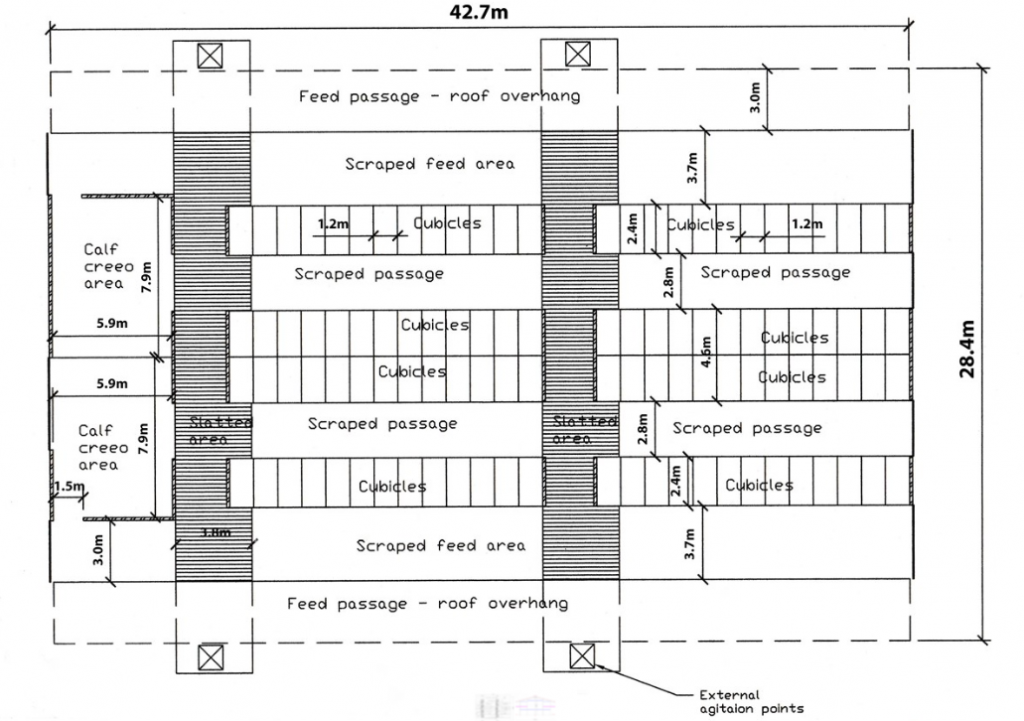

The new housing facility was erected by Rossdrum Engineering. The new cubicle shed is 28.4m wide and 42.7m long. The unit stands 8.9m at the apex and 4.3m to the eve gutters.

The concrete walls of the shed stand 2.4m high. The slatted tank is 28.4m long and 3.81m wide. There are two agitation points at either end of the two tanks that are 2.4m deep. The two feeding passageways at either side of the cubicles are 42.7m long and 3.05m wide.

The two passageways that lead to the feeding barriers are 36.7m long and 3.7m wide. The two internal passageways between the two rows of cubicles are 36.7m long and 2.8m wide.

The 96 cubicles – that were sourced from EASYFIX – installed in the unit are 2.4m long and 1.2m wide.

The calf creep area is split in two; however, calves can access both pens through a 1.5m-wide access gate. The creep area in total is 16m long and 5.9m wide. Calves can be fed – without having to go back out to the cubicle area – at either side of the shed.

Features

The spec of the shed is something you would be accustomed to seeing on a dairy farm. However, Sebana was adamant about installing the best of everything and that is what she did.

The slats were supplied by Mulleady Concrete, in Co. Longford. The concrete was supplied by P. Plunkett Concrete.

No stone was left unturned in this new build; the 96 cubicles – that were installed by John Fagan – were fitted with mats to aid with cow comfort.

The cubicles are split into four segments, which allows Sebana to keep any dry cows and cows with calves separate during the winter period, as she runs both an autumn and spring-calving system.

The water troughs, feed barriers and gates were sourced from Teemore Engineering and fitted by Martin Moore of Rossdrum Engineering.

A Lely Discovery was installed instead of automatic scarpers to clean the passageways leading to the feeding barriers and cubicles.

Sebana explained: “The main reason for going with the collector instead of the automatic scrapers was that I was afraid of the cows getting hurt walking over the scrapers.

I found, from experience, that the cattle manure tends to build up and the passageways don’t seem to be as clean with automatic scrapers.

“Also, there was no difference in cost between the two, so it was a straightforward decision.”

Four DeLaval swinging cow brushes were installed in the cubicle area. Furthermore, two DeLaval mini swinging-brushes were installed in the creep area.

28 clear roof lights were installed in the new unit. Furthermore, a number of LED lights – which were installed by AMC Electrical – were fitted.

On one side of the shed, windbreakers were installed. On the other side, galvanised sheeting was fitted from the top of the eve gutters down to the concrete floor.

She explained: “When the shed is at capacity, I was afraid that it might become very stuffy. So, I was against putting in walls and galvanised sheeting on both sides of the shed; ventilation is so important, especially when there is such a large number of animals in a confined area.

“The windbreakers are a great job and, as well as that, if I ever wanted to expand, I can take them down and build out from that side; however, I can’t see that happening anytime soon.”

In total, there are 10 doorways leading into the shed. Six of these are roller-doors, while the other four are sliding-doors.

She added: “If a cow ever goes down – touch wood that doesn’t happen – I have the opportunity to access each passageway of the shed with ease.

“As well as that, I have a crush and collecting area at one end of the shed and a pen for the calves to go out to at the other end, so I needed the extra access points.

In terms of the crush and loading area, I can lock the cows into one side of the shed and run them through the crush and let them back into the shed through another doorway, without the cows getting mixed, so there are a number of advantages.

“The shed was laid out extremely well and cattle can be managed easily – and more importantly they can be managed by one person, without having to get help.

“I run the farm by myself the majority of the time – as my husband works off-farm – so I needed to make the system as efficient as possible to make the job simple and safe.”

Creep area

As the farm operates an autumn-calving system, Sebana needed an area for her newborn calves to lie down on and have access to feed away from the cows.

Therefore, she opted to install two creep areas that are separated by a 2.4m-high wall and a small access gate.

Each creep area can be further divided into two smaller pens. Furthermore, calves can access the cubicle area – back to the cows – with the help of a creep gate.

Moreover, two roller-doors – in either pen – give calves access to a pen that is located outside – which is bedded with woodchip – and “gives the calves the opportunity to get fresh air”.

Two DeLaval mini swinging-brushes are installed in the calf area, with one in each pen. Four feeding troughs were also installed to feed the calves concentrates throughout the housing period.

Slurry aeration system

An interesting part of the new unit is the inclusion of a – Dairypower Equipment – Slurry Aeration System. The system cuts out the need for slurry to be agitated, according to Sebana.

She explained: “The two tanks are quite big, so I thought this would be the best way to mix the slurry.

“There are pipes lined the whole way around the tank. The aeration system emits bubbles that rise up the tank and effectively help mix the slurry. This, in turn, helps to prevent the build-up of any harmful gases.

I was able to get slurry out on the land over the last two weeks without having to agitate it, so I couldn’t be happier with it.

“The system is supposed to prevent the build of gases as well, so – all in all – I think it was the extra investment. It’s relatively cheap to run as well.

“The actual unit itself is located inside the shed; the area that it’s set-up in is protruding out from the feeding passageway.”

‘The complete housing facility’

According to Sebana, it’s the complete shed that makes the task of managing, handling and feeding of cattle easy and safe.

She explained: “There’s no doubt about it, it is a brilliant job. Everyone that was involved in the build did a super job and I couldn’t be happier with the end product.

I take great pride in what I do and I didn’t feel as if we were doing the cows justice with facilities that we had previous to this new build.

“A lot of the stock had to be outwintered and with the bad weather that we have been getting over the last few winters, it was time to act and install proper housing facilities.

“The only thing we didn’t do was install calving pens because we have a shed for that. Other than that, it has everything you could possibly want to run an efficient beef enterprise during the housing period.”