Sponsored Article

Seeding and fertilising in one with Kverneland

Sponsored Article

Seeding at the right moment and with the right implement is one of the critical decisions you have to take as an arable farmer.

Kverneland integrated seed-drill combinations are developed for maximum ease of use, with a clear layout and a high level of incorporated intelligent technology for active seed-bed preparation and seeding in one.

“The e-drill range offers maximum versatility with one pass operation while the latest addition, the e-drill maxi plus with additional second outlet and adjustable hopper capacity, allows fertiliser or second seed application in the seeding row in just one working pass,” said Leonard Hovenden, Kverneland arable product manager.

The e-drill range is designed to cater for a wide choice of operations depending on the individual farmer’s needs.

The benefits include: independent adjustment of the harrow and drill; close centre of gravity of the unit to the tractor; Kverneland’s well-known CX II disc coulters; ease of use of the ELDOS metering system; and now, the option of grain and fertiliser application in one pass.

“As machinery specialists Kverneland knows farmers need machines that can cope with a wide variety of working conditions, so adaptability and flexibility are key benefits of the e-drill," Leonard added.

As the soil structure is not the same in every field, the e-drill is equipped to allow adjustment of the tine depth of the power harrow independent of the seeding disc coulters as required.

The sowing depth can easily be adjusted hydraulically, while the power harrow is ready for solo operation within a matter of minutes thanks to the coupling hook EURO-CONNECTION - allowing maximum flexibility of use.

The seed hopper is mounted directly on the three-point linkage of the Kverneland power harrow for a positive centre of gravity, reducing the requirement for lifting power, resulting in valuable saving on fuel costs.

Precision seed placement

The e-drill range is fitted as standard with CX-II disc coulters for uniform placement of the seed. The flat cutting angle of the steel disc requires less coulter pressure to reach a constant seeding depth.

Thanks to the combination of steel disc and flexible plastic disc, there is no need for independent scrapers and the coulter is completely maintenance free.

The press wheels ensure the optimum seed to soil contact. Important for a constant seed depth is the distance between the coulter and the press wheel. The close coupling of the CX-II system increases the seed depth accuracy.

“Ensuring consistent seeding depth with the Kverneland e-drill means you can be confident you can achieve the best results for even and consistent germination," said Leonard.

Optimum control

Application rates for seeds and fertiliser are controlled by two units of the well-proven metering device, ELDOS. Both are ISOBUS-compatible and electric driven, which allows fertiliser and seed rates to be adjusted independently.

Via remote control, the driver can carry out the calibration process at the metering device

The ISOBUS e-com 'plug and play' compatibility enables the e-drill maxi plus to be connected to any ISOBUS compatible tractor, for fully functional use by the tractor’s own terminal.

Alternatively, Kverneland’s IsoMatch Tellus Pro or the IsoMatch Tellus GO+ can be used. Both are fully ISOBUS compatible. Non-ISOBUS tractors can be upgraded to ISOBUS standard by the IM Tellus series.

The complete Kverneland e-drill range

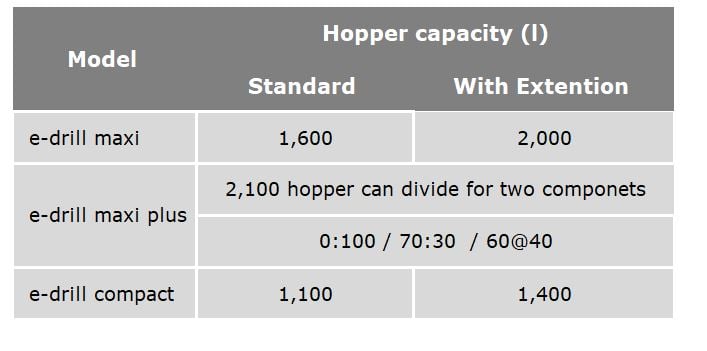

The Kverneland e-drill compact, e-drill maxi and e-drill maxi plus are part of a fully integrated power harrow and seed drill combination range.

The e-drill maxi plus is offered with a hopper capacity of maximum 2,100L, which is divided into an adjustable hopper ratio of 60:40, 70:30 or 100:0, with two independently working metering devices positioned either side.

Two electronic low-level sensors, adjustable from outside, monitor small quantities of rape as well as larger quantities of beans. The full hopper volume can be used when sowing one sort of seed only.

The seed hopper is mounted directly on the three-point linkage of the Kverneland power harrow for a positive centre of gravity, reducing the requirement for lifting power.

The distribution head is mounted directly on the coulter bar, allowing the hopper capacity to be increased to up to 2,100L. The patented hinged hopper-cover can be fully opened for easy filling.

The cover is protected by a bump protection and can flex up to 15°. The loading platform between hopper and distribution head ensures safe access for filling and maintenance purposes. Working lights inside and outside of the hopper allow safe use - even in darkness.

“There’s a lot to look at with the e-drill range: Flexibility, cost savings, one-pass operation with seed and fertiliser to name a few key benefits, so as always if you need any further information we’re [Kverneland] more than happy to hear from you or alternatively, contact your local Kverneland Dealer," said Leonard.

More information

For further information, click here.

Or, speak to a Kverneland representative via the details below:

To find your nearest Kverneland dealer, click here, and to visit the Kverneland website, click here.

Kverneland Group is a leading international company developing, producing and distributing agricultural machinery and services. Strong focus on innovation at the company provides a unique and broad product range with high quality.

Kverneland Group offers an extensive package aimed at the professional farming community, covering the areas of soil preparation; seeding; forage and bale equipment; spreading; spraying; and electronic solutions for agricultural tractors and machinery.

For more information on Kverneland Group visit www.kvernelandgroup.com.

Sponsored Article