Sponsored Article

Video: High-performance ploughs with low operating costs

Sponsored Article

A reliable plough is a must for every farmer and contractor. Due to increasingly changing weather conditions in Ireland, the window to be able to plough is sometimes very short. Kverneland ploughs are renowned for ease of set-up, ease of operation and ease of mind regarding reliability and performance in all soil conditions.

“Kverneland offer both manually and hydraulically adjusted models, but in the Irish market we find the hydraulically adjusted models, known as the Variomat is the most popular, especially the ES range,” said Leonard Hovenden, Kverneland Group Ireland arable product manager.

The Variomat

The Kverneland Variomat has a huge range of features and benefits making it Ireland’s most popular plough. Variomat ploughs allow the optimal match between the soil conditions, the plough and the tractor for the best output.

For the person in the tractor, adjusting the ploughing width from the tractor cabin means no time wasted stopping to change the working width. The Variomat ensures the correct parallel linkage along the whole plough. The pulling line adjustments are hence automatic.

Consequently, low draft requirements and low wear and tear keep running costs low while the field is efficiently ploughed.

Uniquely, Kverneland ploughs are fitted with the multi-leaf spring Auto-reset system that guarantees a non-stop ploughing operation. The plough legs release independently one from another so that once the obstruction is passed, the plough body automatically returns to the correct ploughing depth.

The real advantage of the multi-leaf spring Auto-reset system is that it requires no maintenance, no downtown and consequently reduced running costs.

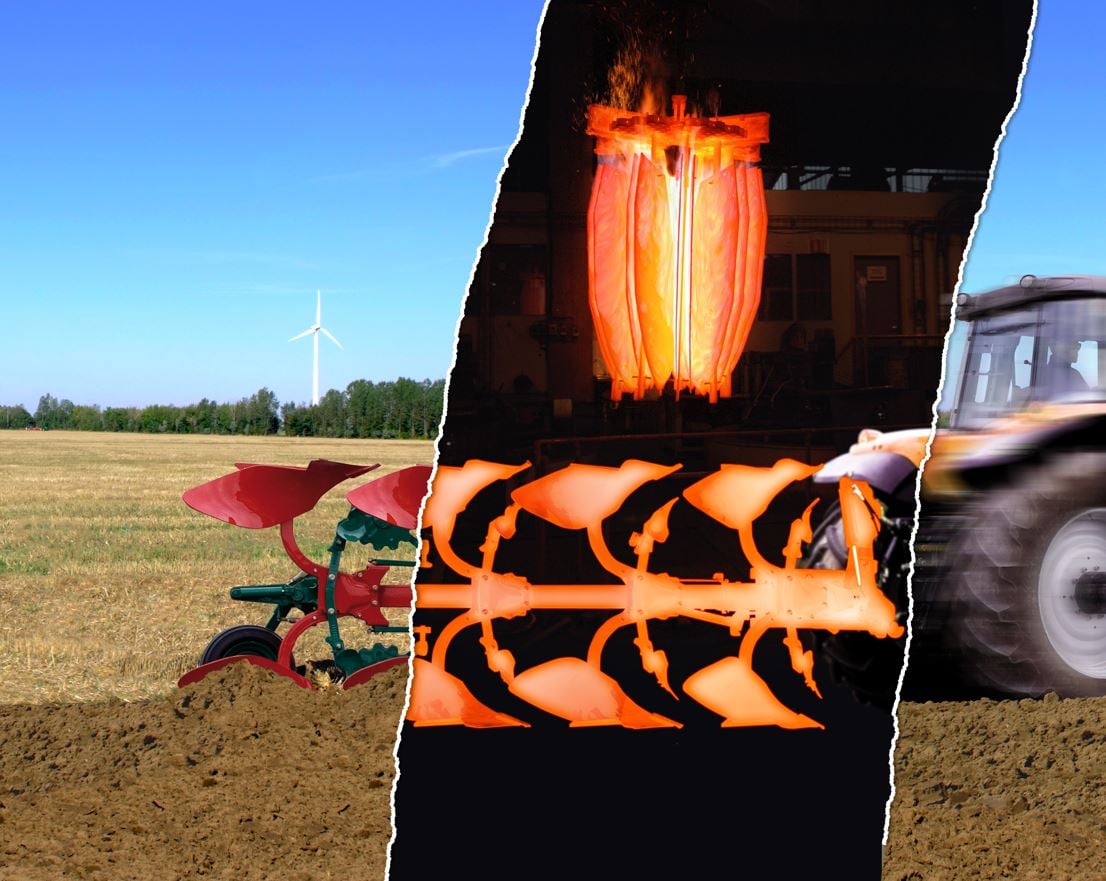

Over 140 years' of experience in developing special steel and heat treatment processes has resulted in a range of ploughs of unsurpassed quality and wear resistance.

The heat treatment process is carried out and adapted not only to a few selected parts but to the complete plough.

This results in ploughs that are lighter than competitors but are extremely robust and strong that deliver outstanding performance.

To guarantee the durability of the plough, Kverneland also heat treats the frame of the plough. At the end of these processes, involving a 12 hours carburising process, the result is a plough with less weight to pull and lift while ensuring a higher wear resistance.

In keeping with Kverneland’s reputation for constant development the newest range of Kverneland ploughs are now working in the Irish Market. The 3300 S range of reversible mounted ploughs feature some of the company’s recent innovations carried over from the award winning 2500 S iplough range.

The aero profile leg, centrally adjusted skimmers, new design of Auto reset leaf spring system and the TTS (trailer transport solution that allows the plough to follow the tractor like a trailer when in transport for increased safety).

All the developments are created with the end purpose of making ploughing more efficient, more productive and more profitable.

Kverneland Packomat

To complement Kverneland’s range of ploughs the company offers the Kverneland Packomat for ploughing and consolidation in one pass.

The Packomat is an integrated soil packer which is directly coupled to the plough, so the weight transfer via the packomat arm means a lighter packer that’s easier to pull and lift when compared to a trailed packer.

By applying a pressure of 1000kg, the wedge-shaped discs cut their way through the furrows, crush clods, push down stones, level and pack the soil. This ensures a quick re-establishment of the capillarity water conductivity for earlier seedbed establishment.

Bodies for every requirement

Quality ploughing requires the correct combination of plough bodies to soil types. Factors such as working width, depth, soil humidity content and structure, ploughing speed and not least, residue types and amounts should be considered.

With the Kverneland range of ploughs comes a comprehensive range of different bodies depending on requirements.

Bodies No. 28 and the newly launched No. 38 are Kverneland’s answer to ploughing with modern farm tractors equipped with wide tyres. These bodies are designed to move the soil further away from the landside thus increasing the furrow bottom width by as much as 25% compared to the body No. 8.

This allows wide tractor tyres, like a 710 width tyre, to work in the furrow without rolling down the previous furrow. Body No. 38 allows for deeper ploughing than body No. 28.

Both No. 28 and No. 38 are longer than body No. 8, and create a flatter profile for improved tilth. The furrow is well turned and packed while requiring as little pulling force as the previous body No. 8.

The enviable Kverneland reputation as a manufacturer of quality, hard wearing ploughs with exceptional longevity, combined with ease of operation, means that a Kverneland plough is a valuable asset. This has resulted in Kverneland ploughs being the No 1 selling plough in the Irish Market with excellent resale value.

Contact Kverneland

For more information on ploughs, click here; and for more information on Packomats, click here.

For any questions, visit the Kverneland website or contact your area manager below:

Kverneland Group is a leading international company developing, producing and distributing agricultural machinery and services. Strong focus on innovation allows Kverneland to provide a unique and broad product range with high quality.

Kverneland Group offers an extensive package aimed at the professional farming community, covering the areas of soil preparation, seeding, forage and bale equipment, spreading, spraying and electronic solutions for agricultural tractors and machinery.

Sponsored Article