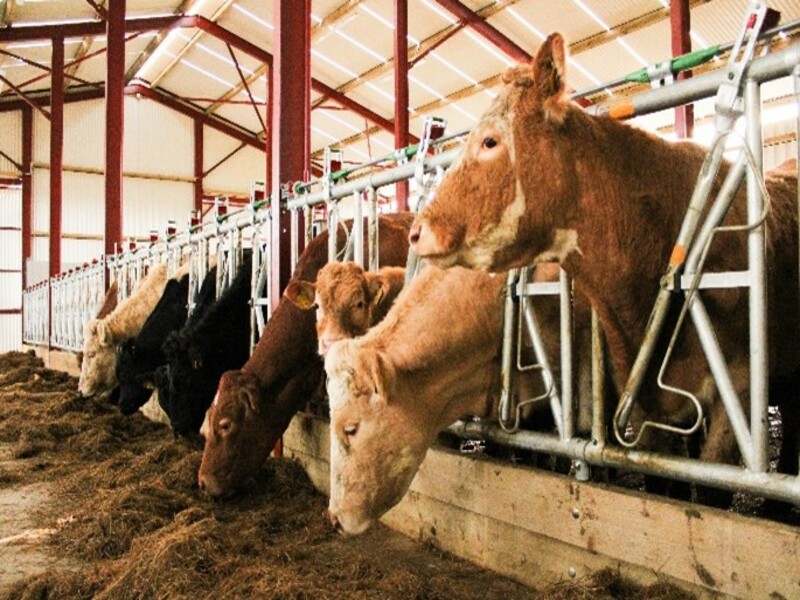

Comfort was a key factor in the recent build of a suckler shed in the Killashandra area of Co. Cavan.

The new four-bay shed makes handling of cattle in a safe environment easy and manageable, by integrating both the silent headlocks and the access arches to allow ease of movement between pens, with minimal disruption.

This was a major aspect that the farmer wanted to get perfect to reduce handling and improve time management when dosing and carrying out veterinary tasks.

“What we wanted was a good, natural flow, to keep animals calm when they go up the crush,” said the farmer, who wishes to remain anonymous.

A creep area was added to the back of each pen, incorporating a Teemore calf creep gate and separate spring-latch gate to ensure easy access to the crush and handling facility from all pens without exiting the shed.

Access to diagonal feed barriers on the back side of three of the four pens allows for the separate feeding of calves from their mothers. This supports feeding calves a separate mix from their mothers, catering more to their growth.

In hindsight, this is the farmer’s favourite aspect of the new shed as it allows him to be more hands-on with the calves’ health, without risking injury from a protective cow.

“If a suck animal has to be treated its easier to get them out through the creep pens,” the farmer said.

In addition to this, cows can be restrained within the headlocks if an animal in the main pen needs treated, building upon the other safety measures put in place.

Access to the shed can be gained from either side: One end, a feeding passage with access for machinery, the other side a narrower passage with access to a crush handling facility.

Ventilation was also key for the farmer in order to maintain control over respiratory diseases and illness; the layout of the shed was designed with this in mind.

Within the shed every inch is being maximised to its full potential by situating the crush along one side of the shed, leading into the back creep area, which links up all the front pens. This ensures minimal movement of cattle, reducing the headaches which naturally come along with the process.

This is essential for the farmer’s current farming practises which sees him as part-time, requiring a lot of the work to completed within short periods of time.

The first creep area has been fitted with a Jourdain EX5 calving and operation gate, which allows the cow to be safely and quickly restrained, reducing stress and pressure on both farmer and beast. In the farmer’s eyes, this has made calving easier and more efficient.

Not only does the calving gate ensure a safe environment for the farmer during calving and support Caesarean sections, but is also beneficial if a cow won’t let a calf suck. Furthermore, it can be essential for strengthening the bond which later determines the calf’s performance.

Slat rubber has been fitted to the slatted area, ensuring cows are surer footed, preventing injury. Slat rubber also provides insulation which aids energy conservation and allows your animals to perform to a higher standard.

As mentioned, comfort was a major concern for the farmer, so the addition of the rubber was a sure deal to improving the welfare standards on his farm.

For more information on this build contact Teemore Engineering on: +44 (0)28 6774 8377, or by email: info@teemoreengineering.com.

To visit the company’s website, click here.