A growing number of calves are group-housed and fed using (automatic) computerised calf feeders during the milk-feeding period. Computerised calf feeders have many benefits including less labour requirements and the ability to feed calves little and often.

Farming in Brandonwell, Ardfert, Co. Kerry, Liam O’Sullivan – alongside his girlfriend Jennifer Scanlon – run a herd of 105 cows and heifers under a spring-calving system.

They rear a mixed breed of calves including Friesian, Limousin cross, Belgian Blue cross and Aberdeen Angus cross. The replacement heifers and a number of the beef-bred calves are kept, while the remainder are sold.

In January 2019 – with the intention to cut down on labour – Liam installed an Urban Alma Pro computerised calf feeder.

To allow for the new system, provisions were made in the calf house in November 2018. Liam extended his calf shed and the layout of the unit provided efficient space for the main unit and three feeding stations.

In addition, 1.5m² of lying-down space was provided per calf, with a 1:20 slope from the bedding area to provide sufficient drainage.

The three-station feeder can comfortably feed 90 calves and a colostrum-management system is in place. This allows each individual calf to be fed colostrum for 24 hours and transition milk for a further two days, while introducing calves onto the feeder on days five-to-seven.

Liam and Jennifer opted to use AAA Golden Maverick to suit his mixed breed calves. The feed curve was set up to feed 750g, which will allow calves to gain 0.75kg/day and the objective is to double the birth weight of calves by eight weeks.

Liam said: “The idea of giving little and often came back to the old traditional way of feeding calves and the calves are extremely content on the feeder.”

Automating the calf rearing process

An investment in a computerised (automatic) calf feeding machine can bring greater control and consistency to the rearing period.

They can also reduce the time and labour required to rear calves. However, to be effective, good hygiene standards and sound overall management are the critical success factors.

According to Una Hickey, National Sale Manager for Volac Ireland, the technology available from automatic feeders is advancing all the time, but the key to getting the most out of these innovative machines is attention to detail.

Teagasc / Animal Health Ireland in conjunction with Dairygold Calf Care Event at Terelton, Macroom, Co. Cork are host John Kelleher and David Whyte, Volac. Image source: O’Gorman Photography

“Rearing calves on an automatic feeder can definitely make calf milk feeding easier and more time-efficient, but it is not an alternative to spending time with the calves. It is essential that feeders are maintained well and that you still observe calves regularly for signs of any problems, such as disease.

“Essentially, we advise farmers that when you make the switch from manual to automatic feeding, you will still be spending a similar amount of time with your calves, but what you will not be doing is spending this time moving the milk around in buckets.

“View an automatic feeder as a way of smoothing out the potential variables in the rearing process [such as inconsistent calf formula mixing rates and milk feeding temperatures], not a short cut to better animal husbandry,” she says.

Siting the feeder

Farmers buying a new automatic feeder typically tend to install them into existing sheds rather than into new, bespoke calf rearing housing.

“First and foremost, make sure you have the right number of feed stations for the number of calves you want to feed. Regardless if the building has been used for rearing calves before, it is important to spend some time making sure ventilation and drainage are up to scratch.

Ideally, pen floors need to slope [1:20] from the back to a drain at the front to ensure the calves are always kept in a clean, dry environment.

Una points out that most automatic calf feeding machines will do two hot washes a day, which means about 10L of water will be used.

“When sorting out your drainage, this issue needs to be considered too,” Una added.

Starting calves on the feeder

Volac recommends that calves can be moved onto an automatic feeder when they are one week-of-age, by which stage the calf should be able to take easily to the feeder and cope well with the move.

“As with all calf-feeding systems, we advise our farmers to ensure calves are fed sufficient high-quality colostrum as soon as possible after birth.

“This means giving them 3L within two hours after birth, followed by another similar sized feed within six-to-12 hours after birth. After this, they should be introduced to a good-quality milk replacer before moving onto the feeder at seven days-of-age.”

Efficiency gains from computerised calf feeding

Initially, the calf should be able to access a total of 6L of performance-formulated milk powder ‘little and often’ – for example, three 2L feeds during a 24-hour period.

“You can programme the feeding curve on the machine, which makes life a lot easier. What’s more, maintained well, automatic machines such as those supplied by Forster Technik and Urban, will always mix calf milk replacer accurately with water and also ensure that the milk is always delivered to the calf at the correct temperature.

“Heifer calves that you want to calve down at 23-25 months-of-age need to be gaining 0.7-0.8kg/day, which means you need to be feeding a minimum of 750-900g/day of good-quality milk formula, such as Volac’s Lifeguard range, to hit this target.

“This will continue until the calf has been on the feeder for 35 days and then the weaning process should begin,” Una says.

“If you have weigh cells, which are available when installing feeding stations, you can also record a weight every time the calf feeds. This also makes life easier because you will not be handling calves separately to weigh them.”

Weaning

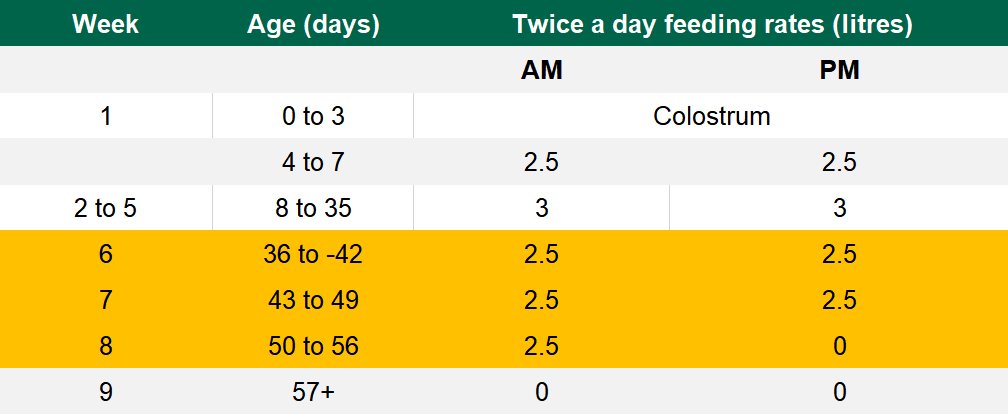

Volac advises gradually reducing the amount of milk offered to calves, over a three-week period between days 35 and 56 (see table below). This encourages starter intake, helps rumen development and improves the ability of the calf to digest nutrients after weaning.

“For the high milk fed calf, we now recommend a three-week weaning period between days 35 and 56 where milk replacer is fed at ≤ 750g of milk solids/day to ensure calves eat enough starter to allow for sufficient rumen development,” says Volac calf rearing specialist, Liam Gannon.

Calves that are fed more milk over the first five weeks of life will be bigger and more vigorous. These calves will subsequently eat more starter when milk is gradually reduced from day 35 to 56.

What’s more, calves fed more milk, coupled with good starter intakes, will be more likely to achieve their early growth targets and lifetime milk production potential.

Below is the recommended milk feeding plan with a three-week weaning period (for calves fed twice daily). Stepping down period is shaded orange.

The reduction in milk solids per day will be specific to each individual dairy farm. For detailed advice on stepping down milk powder feeding levels on your unit – and making the most of computerised calf rearing machines – please speak to your local Volac Business Manager.

- Spend time familiarising yourself with your machine and make the most of all its various functions;

- Calibrate your machine to ensure accurate mixing of milk replacer and check this calibration every four weeks or when a new batch of milk powder is started;

- Always keep the dispenser areas clean and wiped daily;

- Dry sweep areas around calves. Refrain from using a hose, especially a pressure hose, as this will damage the machine and create a wet environment around the feed station, which will encourage bacterial growth;

- Check your machine daily to make sure it is performing at an optimal level. React to any warning alerts. Be mindful of the weather. For example, pipes may freeze in very cold conditions, so make sure you have a contingency plan for these eventualities;

- Good teat hygiene is crucial. Clean and change teats regularly. Teats can be soaked in a solution of disinfectant and replaced in the morning and afternoon. It is good practice to alternate the station teats on a daily basis;

- Run the in-built cleaning cycle programme regularly. Full circuit cleaning should be performed at least once a week. Clean the machine thoroughly between each batch of calves;

- If you identify any repeated issue with a machine (e.g. not cleaning or calibrating properly), contact the equipment supplier or your service engineer;

- Ensure you always follow manufacturer cleaning and maintenance instructions;

- Make sure your machine is serviced annually.

More information:

For more information, visit Volac’s website at: www.feedforgrowth.com or just click here