Modern day concentrated whey protein-based milk powders can deliver top notch calf performance thanks to careful processing and delivery of essential bio-nutrients.

It’s time to debunk the myths around whey-based milk powders and take the time to select the right quality calf milk replacer (CMR) to maximise the potential of your heifer replacements, says Ian Watson, global technical manager at Volac.

He believes there is much to be gained from choosing modern day, whey-based calf milk replacers. “Whey powders historically started out with a poor reputation, but advances in processing and research means whey is now a go-to protein source.”

There is still the perception among some farmers and advisers that skim milk powder is best as it forms a casein clot in the abomasum, which breaks down over a period of time. This is perceived as beneficial to calf performance.

However, recent research suggests there is no difference in growth and calf health when calves are fed high-quality skimmed or whey-based products (see ‘whey versus skim trial’ panel below). This could be attractive to farmers considering the fact skim products can be higher in price.

Watson says it is also important to recognise that skim products may not be the same as they once were. In some cases, skim powder inclusion rates have dropped from 60% to around 10%.

“There can be wide variation, so it’s always important to check the amount of skim included in the powder as this directly affects the clotting effect of the casein,” he says.

Why whey?

Whey also has a number of additional benefits not found in skim products. For example, the whey fraction of colostrum and whole milk contains valuable bioactive proteins, such as immunuglobulins and lactoferrin.

Volac filters and concentrates up the liquid whey protein fraction of milk and retains the key proteins, fats, sugars and other bioactive components. The resultant unique ingredient is Imunopro®, which is included in its calf milk formula range.

This concentrated whey protein and phospholipid base material is packed with vital amino acids, lactoferrin and immunoglobulins. While immunoglobulins are absorbed by the calf’s gut in the first 24 hours to provide immunity, they also help rapid gut development and lay a solid foundation for fast, efficient growth.

Lactoferrin is also important for the development of the immune system and has antibacterial properties in the gut.

Watson says it is important to recognise that not all whey powders are produced in such a way and, as such, not all wheys are created equal. He urges farmers to check with their CMR supplier as to how their products are processed.

“It’s important to understand that processing can impact on the raw material and the digestibility of that material and the nutrition delivered,” he explains.

For example, low temperature processing helps safeguard essential amino acids and aids digestibility. Checking exactly what type of whey is included is also an important process.

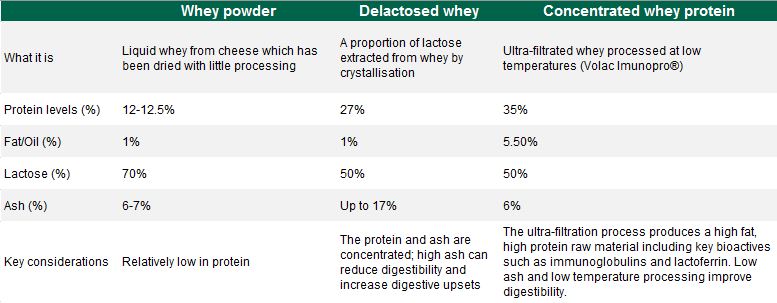

“What is declared on the label? Is it delactosed whey, whey powder or whey protein? All three originate from whey in cheese but have been processed differently [see table 1: know your wheys],” he says.

Key things to think about when selecting a milk powder

Protein:

- For dairy replacements opt for a product of around 23-26% crude protein;

- If your cows are true Holstein and you want frame, choose a product at the higher end, although 23% crude protein can still achieve good results;

- For dairy cross beef calves, 20-23% crude protein may be more economically viable;

- A 23% crude protein CMR can work well for both dairy and beef.

Fats and oils:

- Oil acts as an energy source;

- High oil products (>20%) are available but increasing the oil and energy levels can make weaning onto dry feed more challenging as calves will not have the desire to eat hard feed. This can be compounded by feeding high milk feeding rates of >900g of milk solids per day. To minimise growth checks on high oil products, and/or high milk feeding rates, a robust step weaning process is essential, ideally over a three-week period.

Fibre:

- Fibre is an indication of vegetable protein inclusion (there is no fibre in whole milk). Ideally levels should be 0.1 or below;

- High fibre will reduce digestibility.

Ash:

- Ash levels of 7-7.5% are ideal;

- Do not go above 8% as this will reduce digestibility.

Sodium, phosphorus and calcium:

- Sodium is an undesirable salt – you do not want levels higher than 0.5%;

- High sodium suggests more ash and potassium which reduces digestibility and increases the risk of digestive upsets;

- Phosphorus should be 0.5-0.6% and calcium 0.8-0.9.

Whey vs. skim trial

Farmers can expect similar calf performance when feeding either high levels of whey-based or skimmed milk powder, according to recent research out of the Agri-Food and Biosciences Institute (AFBI), Hillsborough.

The trial aimed to bring historic calf milk replacer research from the 1990s into the 21st century by comparing performance of whey and skimmed milk powders fed at modern day feeding rates.

80 Holstein Friesian calves were fed up to 1,050g of milk solids per day and growth rates and disease incidence were monitored up to 10 weeks-of-age. The results showed that the presence of the skim, and, therefore, the clotting effect of casein, was not needed for calf performance.

Volac research scientist Dr. Jessica Cooke says: “There was no significant difference between the different milk replacer formulations. If the important milk components are processed at low temperatures and with careful manufacturing techniques, both skim and whey proteins will be highly digestible by the milk fed pre-weaned calf and will deliver good performance.”