There tends to be a lot of interest in calf housing this time of the year, with the calving season on many dairy farms not that far away.

A couple of farmers have been in touch wondering what other farmers have done in terms of calf housing and were looking for some ideas. In this article, we are going to take a look at a conversion job from an old cubicle house into a larger calf housing facility.

One conversion job that AgriLand visited back in 2019 was on the farm of Pat Rochford from Gortnahoe, Co. Tipperary.

At the time, Pat was milking a herd of 90 cows and, by that stage, his old calving facilities were too small for his expanding herd, so he decided to covert an old cubicle shed that was used for weanling heifers in times gone by and convert it into a calving area and large group pens for calves.

The shed that he converted was originally split into three sections. The two outer sections were cubicles, while in the middle of the two cubicle areas was the farm’s original calf housing facilities which included small group and individual pens and a passageway, where the cows used to actually calve down in.

The old calf housing facilities were able to hold 60 calves, but as cow numbers crept up, space got tighter and tighter and it led to Pat having to rethink his plans for more calf space.

Expansion

Telling his story, Pat said that the final part of the farm’s expansion phase was to build a new calf-rearing facility that could accommodate the increasing number of calves being produced.

Pat said: “The two things I really wanted from my new calf shed were plenty of ventilation and to keep a small part of the old calf shed that included the individual calf pens, which I feel didn’t warrant being knocked down.

“Originally, when I spoke to Thomas Gleeson, of Gleeson Steel and Engineering – who carried out the conversion job – he wanted to knock the entire shed and start from scratch.

“However, I told him that I wanted to keep some of the existing calf shed and one of the old cubicle houses that I house my weanlings in during the winter.”

Layout

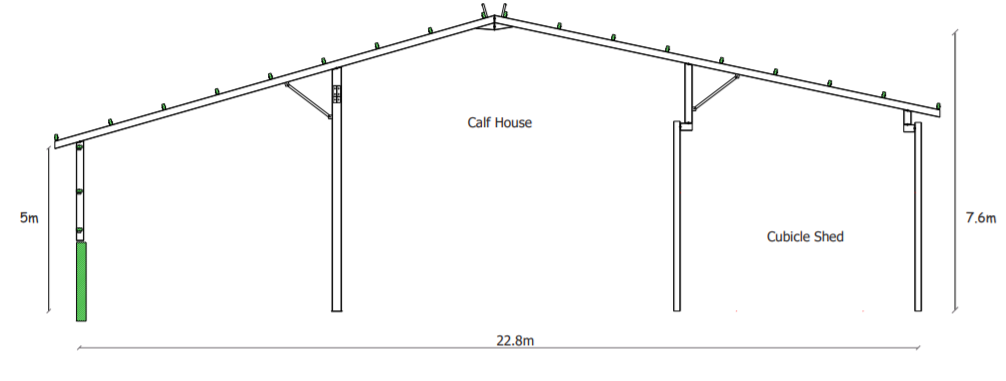

The shed is 7.6m high at the apex and 5m to the eve gutters. It is 22.8m long and 22.7m wide. The mass concrete walls stand at 2.4m.

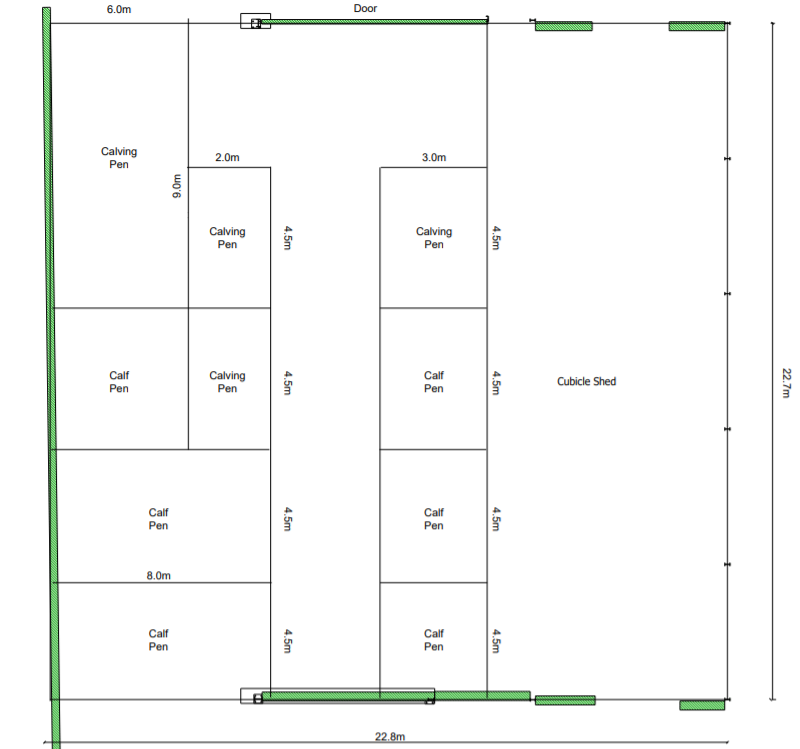

The unit contains 10 pens. There are six pens dedicated to the calves and four pens for the cows when they are ready to calve.

There are two pens that can hold up to 25 calves. These pens are 8.0m long and 4.5m wide. The remaining calf pens are smaller and can hold between six and eight calves each; these pens are 3.0m long and 4.5m wide.

There are four calving pens; the largest of these can hold up to 10 cows. This pen is 6.0m long and 9.0m wide.

The remaining three calving pens – which contain a calving gate – are 4.5m long and 3.0m wide.

Features

Two elements of the design that Pat wanted from day one was a high roof with good airflow and plenty of access for a tractor to come in and clean out the shed with ease.

Safety was one of the key reasons for the investment along with the need for more calf housing.

The old calf shed was structurally unsound and in need of refurbishment. In the summer of 2018, the roof on the hayshed and the lean-to was taken down.

Pat added: “I was exceptionally tight for space to house my calves and not only that but the old shed was quite clammy and warm.

“When I met Thomas I told him the two things I wanted: a high pitched roof; and plenty of space to move around in the shed.

“There are two sliding doors located at either end of the shed. At one end, cows that are close to calving can enter through the sliding door into the large calving pen.

The cows usually calve in the big pen but, if I need to pull a calf, I can move the cow into the individual calving pen, where the calving gate is.

“The gates are interchangeable, which makes it easy to move cows from pen to pen.

“When the cows calve, I can move the calves into the individual pens before they are moved into the larger pens when they are used to drinking milk.”

The calving gate (pictured below) can be used between the two calving pens and there is a metal sheeting incorporated onto it to prevent calves from moving between pens.

There are two 5 Bar Man Escape gates installed in the calving pens. This allows Pat quick access to exit the pen and also allows him to take a calf out of the pen without having to open the main gate.

There are heavy and lighter gates installed in the shed. The heavier gates are installed where the cows are housed and the lighter ones where the calves are kept.

Moreover, there are five double water troughs installed in each of the pens. However, Pat is looking to install smaller water troughs in the future.

Individual and group pens

One of the unique features of this shed is the fact Pat kept part of the old calving shed. The new extension consists of calving pens and large calf group ones, while half of the old shed was kept intact and consists of individual pens and small group pens.

Pat added: “I felt that some of the old calving shed could be useful and didn’t warrant being knocked down. The way the shed is laid out now, the calving pens and the individual pens are beside each other and it makes moving calves easy.

“Once the calves are suckling and are fit to feed themselves all I have to do is open the gate and put them across into the large group pens.

It’s all about being efficient and getting jobs done quickly, as calving is an extremely busy and stressful time on farms.

“As well as that, my father built the old calf shed back in the 1970s and I couldn’t just knock it either. It served us well down the years and it continues to do so.

“Then, in terms of the large group pens, they give you great comfort, in that you can hold a large number of calves and feed a sizeable amount at the same time. Calves need to be kept on-farm for at least 10 days nowadays so having big pens like these takes the pressure off big time.”

Ventilation

The high pitched roof allows for good airflow throughout the shed. However, Pat had to install windbreakers between the old cubicle shed and the calf house as there was a draught coming through.

“The windbreakers are a great job; there was a strong draught coming through the shed and I was afraid of calves getting chills and pneumonia.”

Above the mass concrete walls around the shed is vent sheeting, which further aids the circulation of airflow throughout the shed.

Another aspect of the design is the inclusion of five clear roof lights for each span of the shed.

It was only installed on one side of the shed – where the calves are – to keep out the draught that comes through the small gap between the door and the galvanised sheeting.

Pat noted: “The calves tend to lie at the back of the pen and I noticed a draught coming in and I got on to Thomas who got the brush fitted onto the door.”

Cost

The overall cost of the build was €70,000 excluding VAT. As well as Gleeson Steel and Engineering, Fogarty Concrete and Condon Engineering were also involved in the construction of the shed.

Commenting on the build, Pat said: “I am delighted with how it turned out. The great thing about the shed is that it can be used for a range of different things.

“All the gates and poles can be taken down within a matter of minutes. I can use the shed as storage space after the calving season or if I need to house cattle at some point throughout the year.

“The fact that I can operate machinery in the shed without the fear of having to watch where I am going constantly is a plus, as this was a major issue with the old shed.

When all the gates and poles are taken down I can come in with the tractor and loader and clean out the shed in two hours.

“The fact that I don’t have to get calves out of the shed as quickly as possible at calving time – now that I have the room to house them comfortably – means I have one less thing to worry about come springtime,” Pat concluded.