At the foot of the Silvermine Mountains, in Co. Tipperary – off the beaten track – lies a brand new suckler and beef unit.

The new facility was recently erected on the farm of John and Alyssa Treacy, who after a few years working abroad, decided to come home and take over the running of the farm from John’s father – on a part-time basis.

Instead, John started out buying in continental-type weanlings and finishing them.

However, over time, John felt it was time to change up and go down the route of buying in dairy-bred calves and finishing them. Although, this year, John plans to sell them at the mart at 18 months-of-age – all going well.

Speaking to John about the system he has in place and the new shed, he said: “Up until the winter of 2018, I was housing my cattle in an old dry shed that my father would have used for years.

When I came back to Ireland, my intention was to build up a herd of cows; however, the cost associated with starting such an enterprise led me to try out a few different systems.

“Up until last year, I brought all of the calves – that I would buy off local dairy farmers – to beef. However, as of now, I have decided to sell them off at 18 months-of-age unless I feel I can get them factory-fit without having to go mad feeding them concentrates.

“I hope that in a few years I can switch over to sucklers. The shed is designed in a way that I can house both beef cattle and also calve down cows.

“I suppose another reason for building the shed was for my children – Liam, Sean and Finn. They love farming and in years to come – when they take over from me – at least they will have good facilities to start off with.”

Layout and site

John designed the shed himself before sending the draft away to Dan Fahey – of Dan Fahey Architectural Design – who did up the drawings for him.

Due to working full-time off-farm, John said that he needed to invest to make the task of managing his cattle that bit easier.

Construction began in June of last year and it was finished the following August.

Due to the location of the site, a “nice bit of ground” had to be dug out to get the site level. The excavation work was carried out by John Kennedy Agri Contracting.

The concrete work was carried out by Fogarty Concrete. The shed itself was sourced and erected by O’Dwyer Steel.

The new build is a four-bay, double – which also includes a handling area. The unit can be split in two, as one side of the shed contains four slatted pens, while the other side contains four dry pens and a crush.

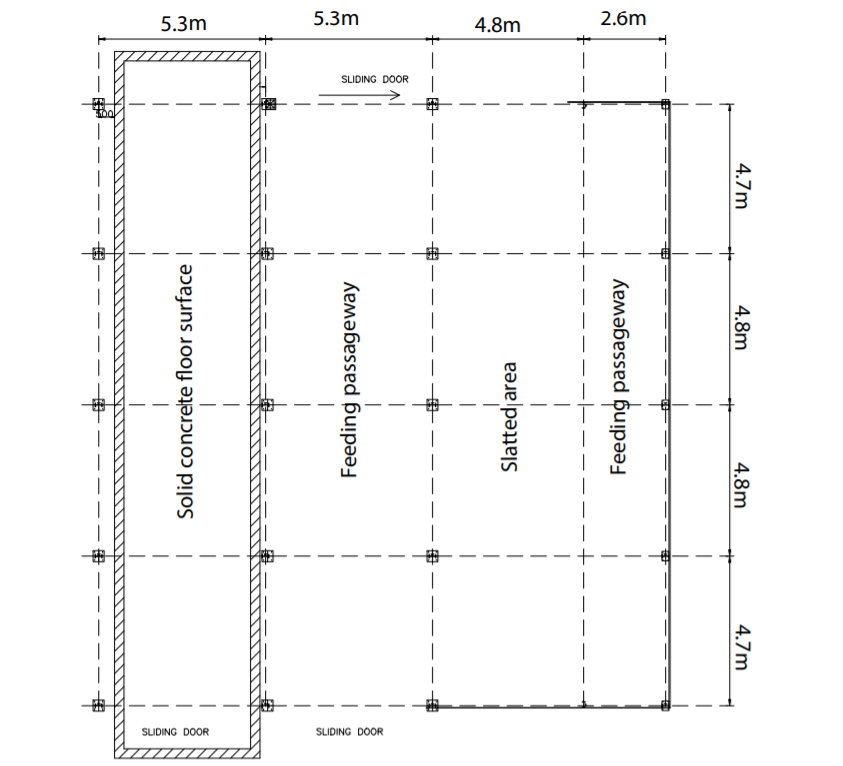

Looking at the design of the new unit in more detail: the building is 19m long and 18m wide, which includes the outer feed passage; the unit stands 3.5m to the eave gutters.

The concrete walls of the shed stand 2.4m high. The slatted area, which consists of four pens, is 19m long, 4.8m wide and 2.4m deep. Furthermore, two of the pens – at either end of the shed – are 4.7m long and 4.8m wide, while the other two pens – in the middle – are 4.8m long and 4.8m wide.

The outer feeding passageway is 2.6m wide and 19.1m long. The main passageway in the middle of the unit is 19m long and 5.3m wide.

The dry area, which consists of four pens, a crush and a platform, is 19.1m long and 5.3m wide.

There are three sliding doors incorporated into the build, two of which are at either end of the feeding passageway, while the other one leads into the dry area, where the crush and pens are.

Suckler and beef unit

Even though John is currently operating a system that sees him sell his cattle at 18 months-of-age, or in some cases bringing them on until they are fit for the factory, he still hopes to build up a herd of cows in the near future.

This is the reason why he opted to build a shed that would allow him to house beef cattle as well as keeping cows; hence, the reason behind the four dry pens – that will allow him to calve down cows.

Speaking about his decision to build a shed that would allow him to keep beef cattle as well as calve down cows, John said: “I’m trying to get into the suckler game, but there doesn’t seem to be much money in it at the minute.

“I designed the shed in a way that if I want to go down that route I will be able to, so hopefully sooner rather than later, I’ll be able to go in that direction.

The system I’m running at the minute is going fairly well for me. I was paying up on €800/head for continental weanlings and finishing them, but I wasn’t seeing much of a return from it.

“So I decided to change and go down the route of buying in dairy-bred calves. With the dairy-bred calves, you might make €400/head less with them compared to the continentals but they will cost you €400/head less to buy.

“If you can get the right calves you would be surprised how well you can bring them on. I finished some last year and I was very happy with how I got on with them.”

Slatted area

In order to keep as many options open, John decided to incorporate an outer feeding passageway instead of putting up a precast wall, that would normally be seen in many builds.

According to John, it gives him great flexibility in terms of how he can house and feed his cattle.

He explained: “By having two feeding passageways it gives me options. If I wanted to finish cattle, for instance, I could feed them on the outer feeding passageway and open the feeding barriers in the middle passageway and have a dry area for the cattle to lie on instead of them having to lie on the slats.

“It is very handy if I wanted to that, especially if I don’t have cows, because if I did I would have to feed silage in the middle of the shed.”

John added: “People might say that there would be a strong breeze coming through shed but because it is so well sheltered by the surrounding trees, it is never the case.

“It’s ideal in fact, the shed is never too stuffy or cold, which is great. I hadn’t been farming for years, so when I got home and took over I didn’t know what system to go with, so I suppose if I do change again I have a shed that will be able to facilitate that.”

As is the case with grant-spec sheds, vented sheeting was installed, along with clear roof lights. Fixed and swinging gates were erected between the pens in the slatted area.

Dry area and handling facility

On the other side of the shed lies four dry pens and a crush, which has a shute for John to handle his cattle safely.

He hopes to be housing cows on this side of the shed in the near future. As of now, it is getting very little use. However, come next spring, it will – hopefully – be home to calves that John plans to buy from local dairy farmers.

On the other hand, the handling area has gotten great use so far, which he says has been a great investment.

John explained: “The best thing I did was to install a crush at the back of the dry pens. It’s amazing how quickly you can get jobs such as testing or dosing done in such a short period.

“The shed is laid out in a way where the cattle can basically go around in a circle.

“So, just say I have weanlings in the slatted area, I can open the feeding barriers out into the feeding passageway, which basically creates a holding area for the cattle – until I am ready to let them up the crush.”

He added: “Furthermore, I can do the exact same on the other side. Once the cattle exit the crush they can run from the dry area across the feeding passageway into the slatted pens. This means they can’t get mixed with the cattle on the other side that haven’t gone through the crush yet.

“Between the dry pens and the crush itself is a shute that has a platform, which makes it easy and safe for me to handle the cattle.

“I had a herd test there towards the back end of last year. In the space of 15 minutes, we had the 45 cattle that I have tested.

“It’s amazing, once you have the proper facilities you can get jobs done quicker, which is crucial if you’re working full-time off-farm.”

‘Going for the grant is well worth it’

The project was carried out with the aid of the Targeted Agricultural Modernisation Scheme (TAMS).

Commenting on the new build, John said: “I’ve heard people saying that it’s not worth going down the route of applying for a grant to build a new shed; however, I can tell you now that it 100% is.

Once you get your paperwork in order and do everything right, it is a straightforward process.

“The planning went in January of last year and only for the fact that we had to wait for the weather to dry up we would have had it finished before August.

“I am delighted with it how it turned out. I have a facility there that will accommodate any type of system that I want to run – which is exactly what I wanted.”