Farming in Glengoole, Co. Tipperary, Padraig Troy runs a tidy and efficient suckler-to-beef enterprise. The farm – which stretches across 130ac – is home to 75 suckler cows.

Padraig operates a spring-calving and an autumn-calving system. Calves born in the spring are sold as stores around mid-April of the following year. Bulls born in the autumn are brought to slaughter at 18 months.

Every year, Padraig – who also works off-farm – buys 20 Limousin bull calves from his brother, Seamus, who runs a dairy farm a short distance away. These bulls are reared and finished on-farm and are slaughtered at approximately 24 months.

This year, only two cows from the spring-calving herd are left to calve and bull weanlings are currently grazing silage ground.

As Padraig works off-farm, simplicity and ease of management are crucial factors when it comes to managing his enterprise. With that in mind, the decision was made to remove one half of an existing shed and construct a new six-bay slatted unit in its place.

“My brother Seamus is dairy farming down the road. I work full-time off-farm. Some days I work 7:00am to 7:00pm, so he would come up and do the herding and whatever has to be done. In turn, I give him a help out too; we work well together.”

In relation to the project, he said: “Two reasons drove me on to build the new shed. The passageway in the original unit was too narrow. It was too difficult to feed because I couldn’t turn with the tractor; it just didn’t work.

“The second reason was space. Some of my cows were out-wintered because I need to finish my bulls indoors. The cows couldn’t come in until the bulls were sold in January or February,” Padraig explained.

“However, I now have space for every animal I have during the winter. It is very handy to handle animals in the new shed. I can move cattle around the shed if needs be; it definitely suits my operation.”

Dimensions

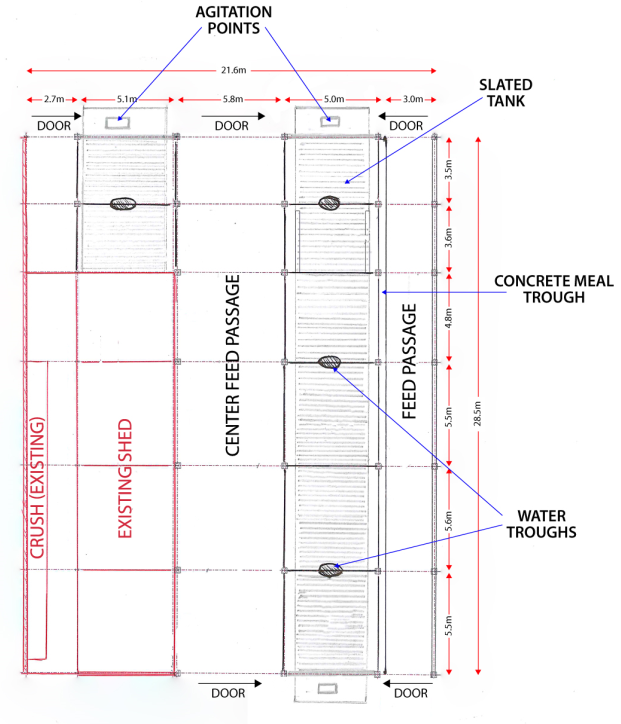

One half of the original shed was taken down and a slatted tank – measuring 94.4ft long, 12.6ft wide and 8ft deep – was constructed.

The shed itself is 28.5m long and 21.6m wide. It is 4m high to the eve gutters and 7.6m high to the apex. An additional two bays – measuring 3.6m and 3.5m in width – were added on to the existing unit; these bays are 5.1m long.

The six bays in the new unit are 5m long but vary in width. The reason being that it had to match with the bays in the other half of the shed in the existing unit.

The centre feed passage is 5.8m wide and the feed passage located at the back of the pens measures 3m wide.

Building to match existing shed

When it came to building the shed over the tank, a clever and well-thought-out plan was needed to allow the new pillars to match to the pillars of the existing shed.

Nicky Sweeney – an engineer at Gleeson Steel and Engineering – outlined how this was done to adhere to grant specifications and regulations.

He said: “When we were designing this shed, we had to make sure that the new build lined up with the old shed. The bays are not traditional bays. Some are wider than others and some are smaller.

“We are supporting the old shed as well; it worked out very well. We put up the new pillars and bolted the old shed to them. Then we cut out the pillars of the old shed. We had a bit of rejigging to do, but it was worth it in the end. It made sense to do that.

“That’s what people who are building new sheds should consider. You’ve got to use what you have. If you put a bit of thought into these projects, you can come up with something very handy,” he explained.

Padraig added: “The small bays are handy at times. I have three pedigree bulls in one of them and it’s perfect for them.

“It’s a great job when handling the cattle. I can let them across from one side of the shed to the crush. There’s no need to go out to the yard anymore. It is very easy to manage everything now.

I can manage on my own and that’s exactly what I need. All of the feed barriers open out into the passage.

“The rubber mats are a great job for the bulls. They are heavy and the mats cushion their feet. I have no problems with lameness and they look more comfortable on the mats,” he explained.

Features

Galvanised agri-perlins are spanned across the roof and were used instead of the normal 6inX3in timbers. These were used as some of the bays are longer than the standard 4.8m. They were also used in the smaller bays to keep the shed uniform.

Nicky added: “They are a great job because they brighten up a shed as well. They work very well in a dairy or parlour; they are very clean and bright.”

Padraig used galvanised steel throughout the shed. On this, he said: “The reason I went for the galvanised over the painted version is simple; I want the shed to last for a long time. In years to come, I don’t want to be painting them.”

Access to the shed is granted through four sliding doors – two at either end. Natural light is provided through 12 skylights, which are equipped with safety bars. There are also four agitation points located externally on the entire unit.

Vent sheeting is installed along the length of the structure to improve ventilation. A 450mm gap was left between the vent sheeting and the roof to assist airflow. A 1.5ft overhang on the roof provides adequate shelter, while not interfering with airflow.

X-braces provide extra support to the shed. Tip-over water troughs are located throughout the unit and a concrete meal trough – located at the back of the pens – allows Padraig to feed his finishing cattle with ease. The meal bin is located close by, which keeps labour to a minimum.

Padraig also spoke about the ‘open-face’ style of the unit. He said: “I have the option to sheet down the face of the shed, but I don’t think I will do it. I put the cleats on it for the option.

“I wanted to see what way the first winter would go and I’m happy enough to leave it open because there is plenty of air in the shed.

“The only problem I had was when it snowed. But, hopefully we won’t be getting anything like that again in the future. It wasn’t too bad, but I was glad to see the back of it,” he explained.

The cost

The shed was designed, supplied and built by Gleeson Steel and Engineering. The old shed that was taken down was moved across the yard and re-built by the same company. The fit-out – including the hanging of the feed barriers and gates – was also carried out by the Tipperary-based company.

On the overall cost, Padraig said: “The old shed was taken down and moved across the yard. There was a lot of work to be done before the new shed was even started. New concrete walls were also installed on this unit.

“We had to build up the base underneath the new shed as well. The groundwork and concrete work was done by local contractor, Patsy Maher,” he noted.

The overall cost of the project (including the re-building of the old unit, the groundwork, the two new bays on the existing shed and the new six-bay slatted unit) was approximately €130,000.

The six-bay slatted unit was constructed under the Targeted Agricultural Modernisation Scheme (TAMS II) and Padraig received a 40% grant.

“I’m extremely happy with the work that was done. I couldn’t fault it one bit. If we could get more money for our cattle, we’d be on the right track,” he said.

Nicky concluded: “The key to this job was making sense of what was there and everything was dictated by that; it worked out very well for Padraig.”