Farming in Ballinlig, Co. Westmeath, Colm O’Reilly and his father Michael – a father-and-son team – milk a pedigree herd of 96 Holstein cows.

The duo operate a spring and autumn-calving system – supplying milk all-year round.

Michael has been milking cows for over 50 years and established a pedigree herd of Holstein cows over 25 years ago.

Before quotas were abolished in 2015, they were milking 60 cows and by the time they decided to build a new parlour they were milking 90 cows.

Therefore, Colm and his father took the decision to build a new parlour beside the existing cubicle shed.

Speaking to AgriLand, Colm said: “It is a privilege to be taking over the farm that my father has built up over the years.

“However, we had to improve the facilities if we were going to operate the farm efficiently.”

The duo already have plans to extend their existing cubicle shed and double its size to accommodate up to 70 cows.

Design

The father-and-son team had different ideas on what they wanted but, eventually, they decided on a 16-unit herringbone parlour and drafting system all under the one roof.

The greenfield site is ideally located to access the two roadways which lead to the paddocks either side of the farm.

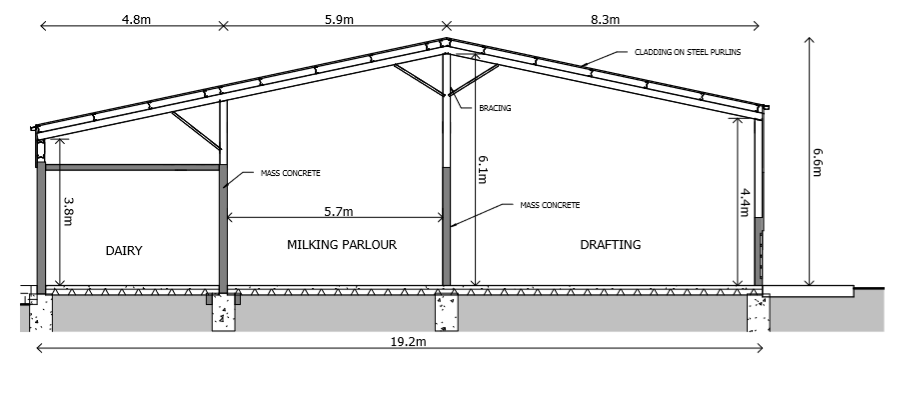

The building is 24.1m long and 19.2m wide. The unit stands at 6.6m high at the apex and 3.8m high to the eave gutters. The concrete walls of the shed stand at 2.4m high.

The 16-unit milking parlour is 19.4m long and 5.7m wide. The stall work is complete to extend it to 20 units if Colm and Michael decide to expand in the future.

When the cows leave the milking parlour they walk through the exit race that will either divert them down the roadway to the paddock or into the drafting pen.

The two drafting pens are 8.0m long and 5.7m wide. The collecting yard – which can hold up to 100 cows – is 9.0m long and 19.2m wide. The yard is split in two, with a slatted tank and solid concrete floor incorporated into the design.

The slatted tank is 3.5 long and 19.2m wide. The tank is 2.4m deep and there are two agitation points at either end.

The concrete floor – in the collecting yard – is 5.6 long and 19.2m wide. There are gate posts in the yard if Colm wishes to hang up gates to split up the cows.

GEA milking parlour

After months of research and discussions with various companies, Colm decided on installing a 16-unit GEA (WestfaliaSurge) swing-over milking parlour.

Incorporated into the milking parlour is a Metatron P21 device that receives data from each individual cow and displays it to the operator in the pit.

The device – which is directly above the cluster in the parlour – can monitor the conductivity of each individual cow and give information on milk yield and if a cow has been administered an antibiotic or is in heat.

“I would be lost without the P21 Metatron device. For example, when I tube a cow for mastitis, I log it into the computer and the next time I go to milk that cow and swing the cluster over to her the machine won’t let me.

“Furthermore, the antibiotic symbol on the screen will start flashing on the device warning me not to milk the cow.”

A 10,000L GEA TCool bulk tank was installed along with a dump line for contaminated milk.

All the washings from the parlour are pumped down to the slatted tank at the front of the collecting yard.

“The automatic feeding system is a terrific job. I can control how much feed I give the cows with the press of a button.

When a cow comes into the parlour, she will get 60% of her meal for that milking allocation. Then, when I swing over the cluster to milk her, the computer will automatically feed her the other 40% of her daily intake.

“I have the feeding system set up in a way that when the first cow arrives at the first feeding trough there is a 10-second interval for when the next feeding trough fills.

“I have it done this way to ensure the cows don’t stop halfway up the chute because if the feeders fill up at the same time it would take ages to get them all in and start milking.

“The gate at the back of the parlour will automatically close when the last cow arrives in and, with a press of a button, the front gate will open when the cows finish milking,” Colm added.

Drafting unit

Included in the build is a drafting unit, that Colm believes was well worth the extra investment.

“It saves a lot of time when it comes to looking for cows that are in heat because the system is set up to detect these cows and it will automatically divert them away from the rest of the herd into the drafting pen.

“It’s the same story if I notice a lame cow in the pit. With a press of a button the drafting gate will divert that cow into the drafting pen.”

Furthermore, a Universal Anti-Backing Gate was installed in the crush to prevent the cows from moving backwards in the crush.

“The fact that all the gates are interchangeable makes the job of herding the cattle so much easier.”

The exit race has concrete slats incorporated into it. Moreover, all the washings from the parlour are pumped down this slatted area to the tank at the front of the shed.

Extra features

Colm installed a 12t meal bin, which is at the back of the unit. The build also comprises an office, where all the information from the parlour is fed back into a computer.

A chemical and general storage area are also part of the build. The collecting yard is surrounded by mass concrete walls, which Colm says “takes the bad look away if you were looking out from the house”.

The last feature to be installed in the unit was a small walkway between the building and the mass concrete wall.

The walkway – which is 0.4m wide – allows for quick and easy access from the outside of the build straight into the collecting yard and into the parlour.

Timeline

The build began in March of 2018 and was completed the following January.

The shed itself was erected by F-Con Civil & Structural Engineering and the parlour was sourced from Charleville Refrigeration.

The total cost of the drafting area was €15,800 including VAT.

Commenting on the build, Colm said: “It’s a dream milking in this parlour compared to what we had before.

“From a management point of view, the drafting system takes the hassle out of it for the man in the pit and the cow.

Before it used to take us two and a half hours to milk the cows in the eight-unit parlour, whereas now it only takes an hour and ten minutes at peak lactation.

“I suppose the one thing that drove me to build a new parlour was that I didn’t feel we were doing the cows justice with the facilities we had.

“It took a lifetime to build up the herd to where it is and it was time to reflect that with up-to-date facilities,” Colm concluded.