John and Lisa Phelan – a husband-and-wife team – from Inchorourke, Co.Tipperary, have overseen many major changes to their farm in recent years. parlour

Previously, John – along with his father and brother – milked a 40-cow herd of predominately British Friesians under a spring-calving system. They also finished 100 cattle (bought in as calves) and ran a tillage enterprise (80-100ac of spring barley) in conjunction with the dairy farm.

In 2010, Brendan, John’s brother, acquired more quota through the New Entrant Dairy Scheme and the 130ac out farm was transferred to him. He now milks 130 cows on this block.

However, realising that both the beef and tillage enterprises were unfeasible for them, John turned all his attention to producing milk. Last year, he milked 165 cows and the herd averaged 1,350-1,400 gallons.

This spring, 198 Holstein and British Friesian cows and heifers are due to calve down – 33 of which have already done so.

The area attributed to the milking herd stretches across 148ac; 103ac of which the cows can walk to and 44ac of which is zero-grazed. An out farm – located 11km away – consisting of 50ac is used to rear replacement heifers. Silage is also harvested from this block.

“My father passed away in 2011. This meant that I had to do a lot of the work on my own. I focused my attention on getting the farm to run as efficiently and as stress-free as possible,” John explained.

John is now in a three-way partnership with his wife and mother.

‘It just wasn’t working’

The Phelans had increased their herd size to 112 cows before the ceasing of milk quotas in 2015. However, the milking facilities and infrastructure had remained static.

“The yards were built a long time ago and they were only designed for a maximum of 40-50 cows. It just wasn’t working,” he explained.

In the old parlour, I used to have to run out in front of the cows if I had to draft a cow. The cow flow in the old system was very poor.

John explained that 90% of the time he is the only labour unit on the farm and each milking was taking approximately three hours – six hours in total. This was excluding the time it took to get the cows, carry out the wash-up procedure and shut the cows away.

He said: “All-in-all, it took me four hours to complete each milking. And, by the time you’d have them out, you would have to do it all over again; it was no joke.”

It was at this point John knew it was time for change. As he was the only full-time labour unit on the farm, he decided to turn to technology and excellent infrastructure to assist cow flow throughout the farm.

Because existing sheds were already located around the farmyard, a clever design was needed. In addition, lots of feed space was a top priority. This was to accommodate his zero-grazing system.

The cubicle house

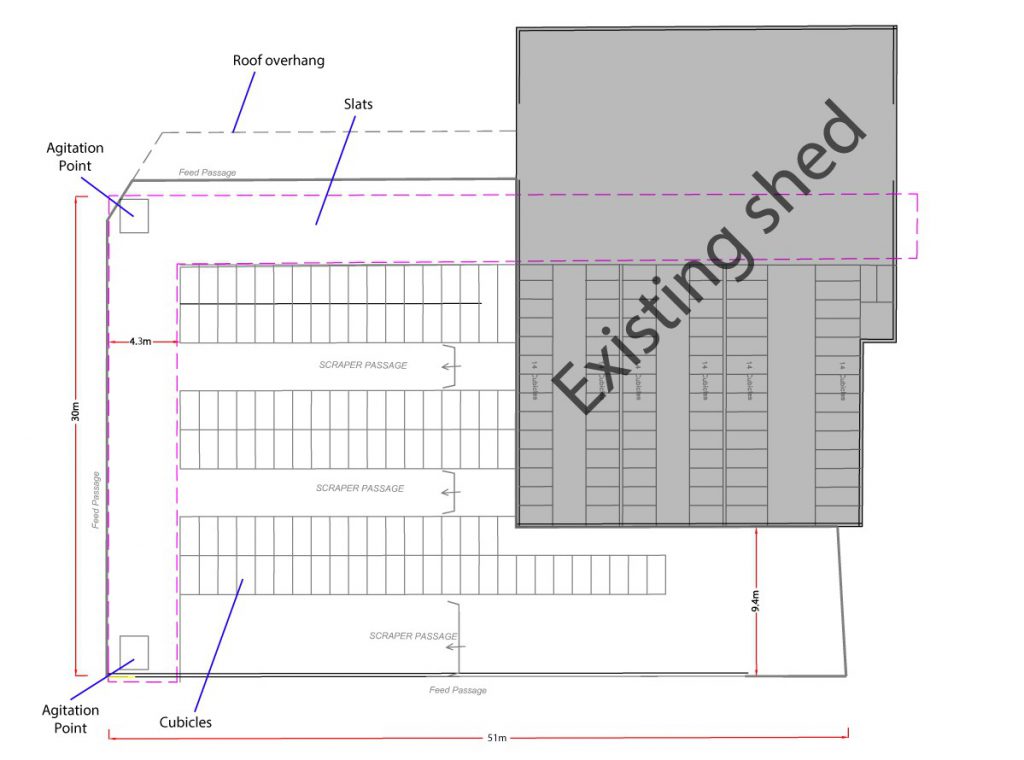

Originally, John had started with the construction of a slurry storage tank and additional feed space to facilitate another 90 cows. An L-shaped tank was constructed the length and width of the shed.

Initially, only a proportion of the cubicles were concrete. John used precast cubicles, so that he could move them around if needed. The tank is 165ft long, 8ft deep and 14.6ft wide.

In December 2016, a roof was placed over the existing cubicles. The six-bay slatted house covers an area of 10,000ft².

On the ventilation aspect of the unit, he said: “I didn’t see the need for side sheeting. It is up plenty high and there is an adequate amount of air getting through it. The overhang keeps the water off the cows’ backs and beds. It also keeps water out of the tanks.

“It is also very fresh inside. I have no issues regarding ammonia and I can’t see that there will be any either. The cows have loads of room and that’s what they need. It also allows me to walk through them easily.”

John also outlined how the headlock feed barriers are invaluable and they are used to carry out many additional tasks.

“They are a bit dearer than the diagonal feeders; but, to me, they make a lot more sense. We even carried out the herd test in the shed three weeks ago.

“It’s a lot quicker than loading the crush. Even when I’m dosing and clipping their tails, I do it in the shed. I have a little generator that powers the clippers; it’s a super job,” he explained.

Sufficient feed space is very important – especially with the zero-grazing system. There is ample space to feed all of the cows comfortably. Together with the 123 cubicles in this shed and an additional 97 cubicles in the adjoining shed, John has more than enough accommodation for his herd.

Automatic scrapers are located on three bays of the shed. Gates located throughout the shed allow John to segregate different groups of animals if the need arises. All of the slurry-storage tanks are linked. There is a 9in pipe going from one to the other and this allows all of the tanks to fill together.

The corner of the shed was designed so that John would be able turn around the shed with the diet feeder and to leave access to the agitation point.

The parlour and drafting system

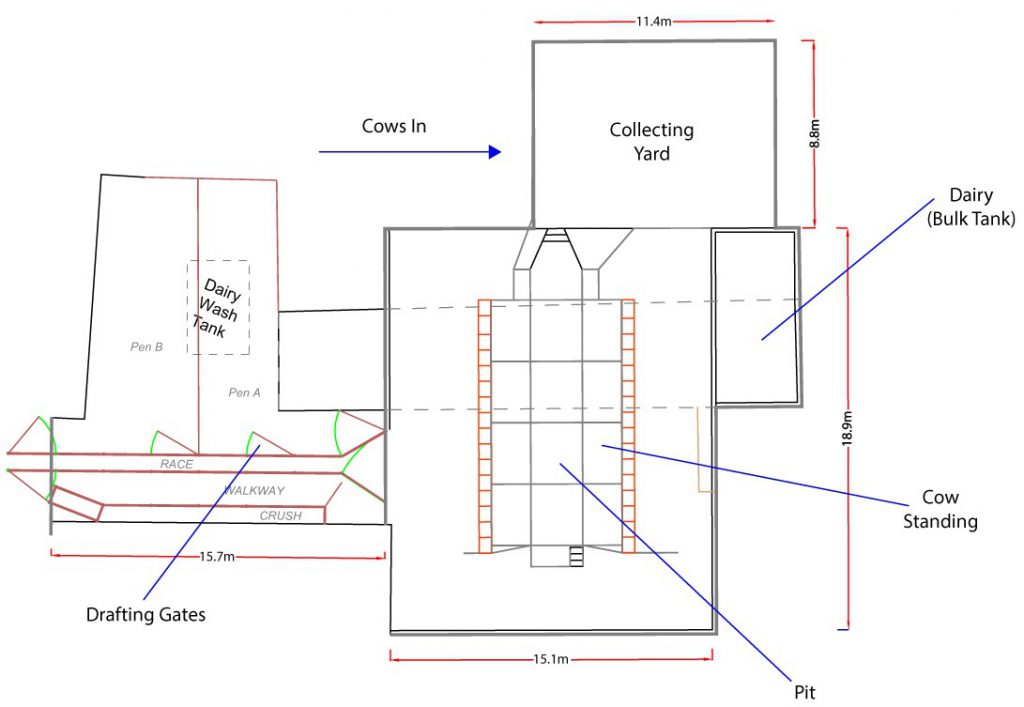

To assist cow flow and to ensure the farm could be ran as a ‘one man show’, John decided to install a 16-a-side, double-up, rapid-exit milking parlour. It was supplied by Pearsons and uses the ProFarm management and feed-to-yield systems.

“I didn’t even go to look at any other parlours. I asked Pearsons for an efficient parlour and this is what they came back with. The rapid-exit parlour is a fantastic job. Once the cows are milked they’re straight out of the parlour. I can milk a row of cows in seven minutes,” he explained.

The grant was solely focused on the milking machine. The reason for this, he said, is because he would have had to wait for the planning permission for the shed. With the milking parlour, he was able to apply for grant aid straight away.

“Last year, I milked the 165 cows in just under 1.5 hours. There is an automatic washing system, so all I have to do is push two buttons and it will wash away.

“The meal is pumped through from an outside meal bin and it fills the hoppers. I top them up after every milking, but you would probably get three milkings out of a full hopper.

“It didn’t take the cows too long to get used to it. The biggest problem I had was that my cows never got meal in the parlour before. So, if anything, they were coming in too quick,” he added.

The i100 keypad allows John to control the feeding and drafting systems from the parlour.

“You can also override everything from the pit. The calving area is located next to the collecting yard, so the cows don’t have far to go once they have calved,” John added.

It takes away some of the observation work. When you’re on your own, you can’t do everything.

“I can also organise the drafting from my phone even if I’m a 1,000 miles away. It takes off some of the pressure; especially at the busy times of the year.

“All I’m doing when the milking is in operation is putting on clusters and teat spraying. Everything else I can do beforehand. If I know there are 10 cows bulling, I can programme the computer to draft them out when they pass through the parlour.

“If I give a cow a tube, I can programme the computer to dump her milk for five days. I’d still mark her in red just to be sure, but the computer is a great job,” he added.

The cost and the future

The roof that was placed over the cubicles and slurry storage tanks was supplied by Gleeson Steel and Engineering. The shed that holds the milking parlour and collecting yard was also supplied and constructed by the same company.

John carried out most of the concrete work himself. On this, he said: “It was an extremely busy period that lasted about three weeks. It was absolute mayhem, but I knew it would all pay off.”

The project was designed by Joe Singleton and the total cost was approximately €350,000 (excluding VAT). John received a grant under the Targeted Agricultural Modernisation Scheme (TAMS II) for the milking parlour. This equated to €55,000.

Furthermore, if we look at the total approximate cost – on a cost per cow basis – the project is priced at €1,489/cow.

On this, he said: “I reckon with the grant and the fact that I’m going to be milking cows for the next 25-30 years, it is only going to cost me €10/milking. That’s the way I’m looking at it anyway.

“You need to be able to get lads to fill in for you – it’s only natural. But, if you don’t have a good set-up, no one will want to come and work for you.

“For February and March, I have a man to milk for me in the morning – once I get about 60 cows calved. Two local men do some relief milking as well.

He continued: “This year, I have one of them booked in for three evenings a week and the other for the morning and evening milkings at the weekends. I’m going to try it for this year and have a little bit more time off to spend with my wife and four-year-old daughter.

“Everything is built now. Hopefully it will be plain sailing from here on. So far it’s working well. The cow flow is super now and it’s less stress for me and the cows.

“Even if I do expand my cow numbers, the milking machine and the yard are all set up for it. However, at the minute, I can’t increase numbers because of the availability of land.

“I hope with the extra time I have on my hands, I will be able to focus on other jobs around the farm,” he concluded.