Farming in Kingsland, Bruree, Kilmallock, Co. Limerick, the Herlihy family has embraced ‘lean farm’ principles to help reduce the length of the working day.

One of 15 farms originally selected to partake in Dairygold’s Leanfarm pilot programme, Liam and Geraldine Herlihy – a husband-and-wife team – have made significant time savings on their farm.

Back in 2011, Dairygold began to implement lean practices across its processing and supply-chain operations. The move proved successful and in 2017 the Leanfarm pilot programme was created to help farmers implement lean practices at farm level.

Similar to the results achieved at processing level, the pilot programme clearly demonstrated that the application of lean principles on-farm also offered significant efficiencies and benefits. These include: improvements in farm safety and quality; better resource efficiency; time savings; and a reduction in stress and physical labour.

Earlier today, the Munster-based dairy processor launched its Leanfarm programme. The Minister for Agriculture Michael Creed officiated proceedings at today’s launch.

Speaking at the event, Minister Creed said: “With significant growth in milk production across the country in the last three years, the dairy farmer’s working day is becoming more demanding.

I believe that Dairygold’s pioneering Leanfarm programme will be quickly adopted by farmers because of the very practical and useful help it provides.

“Seeing how the working lives of the participating farmers are now safer and more profitable, Leanfarm could have a transformative impact on dairy farming.”

Dairygold chairman John O’Gorman said: “We are very excited to launch Leanfarm, which we firmly believe is an initiative capable of changing farming forever.”

Along with the 15 farmers involved in the initial stages of the programme, Dairygold has trained more than 200 farmers in lean farm principles already this year. Further training courses will be offered to Dairygold milk suppliers once the calving season passes.

What is lean?

Lean is a management technique used in business to systemically deliver improvements in performance on an on-going basis. The rolling out of the programme is particularly apt, as sourcing labour continues to remain a difficult task for many dairy farmers.

With an expanded national herd and more cows on dairy farms, any practice that reduces the working day/week/year needs to be given serious consideration.

By cutting down the labour required for day-to-day tasks – or by simply boxing clever – farmers can see a reduction in the number of hours they spend working on their farms.

TIMWOOD – an acronym – is one of the lean tools used to eliminate activities that are not adding value to the business and to help improve the workload.

It consists of: transport; inventory; motion; waiting time; over production; over processing; and defects.

The benefits

From the pilot programme, which was carried out on farms of varying size and scale, Dairygold found a found a number of key benefits.

The Herlihy family are farming just under 100ac and are milking 70 pedigree Holstein Friesian cows under the Kingsland prefix. The herd average production is 1,500 gallons at 3.5% protein and 4.1% fat.

Along with running a successful contract-fencing business, 80-85 beef calves are also brought to the store stage on the farm each year.

Since implementing lean farm principles, Liam’s working day – on average, across the year – has reduced by one hour. A 30% reduction in the number of steps taken daily has also been achieved.

Despite having already made considerable progress under the pilot phase of the programme, Liam and Geraldine will focus on grassland and protein improvements next.

Cows are generally turned out to grass in February. But, it has been exceptionally difficult to get cows out to grass this year. As it stands, 27 of the cows in the herd have calved, after beginning in the final days of January.

Touching on the programme, Liam said: “The number of steps I take each day have reduced by over 30% and we have the necessary implements in every shed now. We are not looking for a pike or a sweeping brush; we know exactly where to lay our hands on them.

It’s the simple things that save you time and I would advise anyone to join up. It’s brilliant. Geraldine added: “We are passionate about lean farming now; it’s given us a new lease of life on the farm, as we’re very focused and interested to find new and better ways of working.

“Being part of the Leanfarm pilot programme has made us see our daily work and way of life with a fresh perspective, and it has empowered us to improve and innovate.

“It was a great privilege to be involved in the programme and it has made a huge difference to our working day. In the past, it used to be a nightmare trying to find things and you’d lose time without even thinking about it. That’s changed now.”

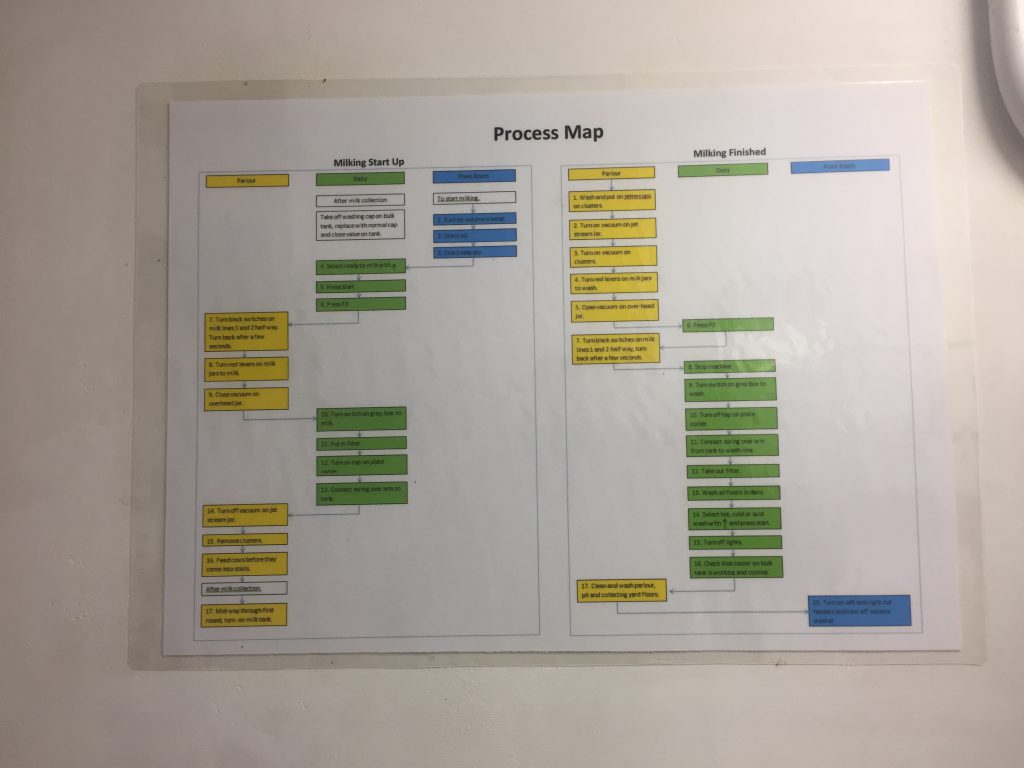

The steps taken by the Herlihy family