The Duggans run a streamlined, low-cost, spring-calving operation on the undulating slopes of south-east Laois.

Eamonn Duggan has been farming full-time here since he was 16 and has witnessed some dramatic changes to the farm over the years.

Eamonn is very focused on his low-cost system, where he grows lots of grass and has a fertile, high-solids cow to enable maximum returns.

The herd boasts an 88% six-week calving rate and 476kg of milk solids sold; when you remove culled cows that are often carried over to June, the figure is 500kg.

The farm is now made up of two main enterprises, the first being the milking cows. The herd will consist of 144 cows and heifers this year – up from the 70 or so cows that would have been milked here in the mid-2000s.

The second is an in-calf heifer enterprise with 60 heifers being sold at 19-20 months.

- The ‘Home Farm’ in Tubberboe – which would have originally been 24ha – has now grown to 36ha;

- ‘Bishopswoods’ – a 30ha owned out-farm where primarily heifers are reared;

- ‘Johnstown’ – a 20ha farm on a long-term lease, which is primarily used for silage production (there are also a few hectares of rough grazing on top of this).

Cows calve and go out to grass thereafter, whatever the conditions. Luckily, the Duggans are blessed with a very dry farm; calving starts on February 1 (this year 132 cows and heifers had calved by March 19, with just 12 left to calve).

Eamonn has a basic yard with no cubicles with the ‘Home Farm’ yard made up primarily of a straw-bed shed and two topless rubber-matted slatted tanks; these also double as the collecting yard.

Last year was a very difficult year for Eamonn with both the snow and drought.

“We have dry ground here in general. During the day time, we go to wetter paddocks for the shorter grazing interval; as soon as cows calve they go out,” Eamonn explained.

Discussion group and grass measuring

Eamonn is a member of the Acorn Group based primarily in south Laois with a few outliners. The group was first started in 1998 and is facilitated by Teagasc’s Fintan Monahan.

Eamonn was also in a Glanbia/Teagasc Joint Monitor Farm Programme which started in 2011, facilitated by Richard O’Brien, and remains part of the core group today, with phase I and II in a discussion group together.

Eamonn measures his grass weekly (twice weekly when required).

“I have been measuring grass for 10 years or more. For me, it is a great thing; it is logical. Once you start you can’t stop,” the Laois-based farmer explained.

Last year aside, in 2017, the milking platform grew by 15t/ha (dry matter). He said: “I’ve gone up nearly 1t/ha over the last number of years. I would have been back down at 10-11t/ha (dry matter) in 2010.”

Herd mentality

Some may question Eamonn on not milking cows on, but to do this Eamonn “would need facilities for those 20 or 30 days.

“I don’t have them,” he said. “I don’t want to pay for them. I try to treat my herd as a herd, rather than individual cows. I don’t look at individual cows; I look at the herd, or at least I always try to look at the herd.”

For ease of management all cows are freeze branded which makes milk recording and day-to-day handling much easier. Eamonn puts it simply: “I like to know my cows and freeze branding reduces mistakes.”

A simple bracelet system is also in place with yellow for slow cows, green for high-SCC cows, red for blind front quarter and blue for blind back quarter.

Co-op Report

Eamonn’s 2018 co-op report places him in the top 15% of Glanbia suppliers for kilograms of milk solids sold at 476kg. As mentioned above, when you remove culled cows, the figure is 500kg.

This is exceptional, particularly in a low-cost system, with the target being to keep costs of production below 20c/L (profit monitor figure).

Key figures that Eamonn focuses on:

- Fat %: 4.48% – so he’s 0.33 ahead of co-op average and 0.06% ahead of the top 10% average (placed in the top 6%);

- Protein %: 3.70% – so he’s 0.19 ahead of co-op average and 0.04% ahead of the top 10% average (placed in the top 6%);

- Calving interval: 366 days – fertility drives the business;

- Calving rate: Six-week calving rate of 88%.

For Eamonn, the co-op report is a useful tool. He said: “I could do things to manipulate the report, but I don’t. The report is there for my benefit.

“In our discussion group, we all send in our litres and solids percentages two days before we meet and Fintan shows us all what we’re getting per litre, per cow and profit per day.

“It really allows you to see how you and your cows are performing. Often, lower-litre cows are outperforming those with higher litres.”

The ideal cow

Commenting on his ideal cow, he said: “A 550kg black and white cow doing 550kg of milk solids would be the ideal cow.

“We’re at about 600kg (weight) doing 500kg of milk solids/cow at the moment. Now, last year we fed 1.7t of meal, but that was for the year that was in it. The year before we did 480kg of milk solids with 700kg or 800kg of meal,” he explained.

The herd’s average EBI at the moment is €135. With the milking platform stocked at 4.0LU/ha – and the whole farm stocked at 2.4LU/ha – performance is important.

“This year we’re nearly at 2.2kg of milk solids/day already. We could peak at 2.3kg or 2.4kg of milk solids/day which would be a high peak for me and there is no question the cows are capable of doing it.

“These cows have been bred from the best genetics for a long time. I’d be hoping to get to 520kg of milk solids/cow this year.”

The target intake would be 16kg/day of grass and 3kg/day of meal. The main limiting factor for Eamonn is days in milk, milking from February 1 to the end of November is 302 days.

“With the average lactation of 270-280 days, it’s a short enough season. But this is my system. I take two months out of the milking parlour regardless.”

For Eamonn, fertility really does drive production.

Last year, 140 cows were milked. This year, it’ll be 144 with 25 of heifers, so the replacement rate is 17% or so.

7% of the cows were empty after breeding last year, with others culled for various reasons; culled cows tend to be carried on the rough grazing in ‘Johnstown’ until June or so.

Breeding

The criteria for sire selection would be in line (usually above) the Teagasc guidelines that Eamonn gets off Richard O’Brien (pictured below), with a little extra focus on fertility, as it is such a key part of Eamonn’s system, with good percentages and no more than 250kg of milk.

Progressive Genetics has the top five bulls on the Active List (ICBF, March 2019); see those sires and more by clicking here

Eamonn has been using Progressive Genetics AI Service since the mid-1990s – Albert Bailey is his AI technician.

The herd is stocked with cows and heifers sired by: AFD; AWB; CFF; DSU; FR2031; FR2032; FR2034; FR2079; HDJ; HMY; HYY; IRP; KJO; LHZ; PBM; PDO; PKA; PKR; PSZ; RDU; SJI; SOK; UPH; WWA; YGD; and others.

Almost all cows and heifers in the herd are February or March born, with just two April-born cows and a handful of January-born cows.

There is a very small amount of crossbreeding, with Jersey sires accounting for 4-5% of AI usage. Triplestar (JE4289) and Superstition (JE4497) were used on the ‘giant cows’ last season.

Cross-breeding on the whole hasn’t been something Eamonn, or his fellow discussion group members, considered as necessary for him.

“I have a fairly steady black and white cow, with decent percentages, going back in-calf with fairly good fertility; plus, I’ve no lameness. I’ve a no problem type of cow.”

Sires of heifers for bulling this spring include: FR2239; FR2297; FR2385; FR2056; FR2371; FR4020; JE4153; and others.

Sires of this spring’s calves include: BJC; FR2233; FR2239; FR2298; FR2460; FR4239; JE4289; JE4497; WWT; LWR; FR4172; and others.

Last year, 25% of the semen used on farm was fresh semen. This would probably have been higher, but Eamonn was involved in the sexed semen trial; the year before fresh accounted for 45%.

Staff

The team is made up of Eamonn and his wife Marguerit and his sons Will, Ned, and Geoff and daughter Isabell. Allen Ryan is also a key cog in the wheel for nearly 10 years fulfilling a general-operative role.

Allen is a shared labour unit doing a week with Eamonn and a week with Eamonn’s brother Sean (Eamonn and Sean also share some machinery).

Adam Whyte also helps out at the weekends. Eamonn describes Adam as “a very good neighbour and a brilliant chap. He has been in and out for a number of years. You just can’t beat having a good team.”

Bigger jobs are outsourced. 80% of slurry is spread by a contractor and all silage work is contracted; plus approximately 40% of the fertiliser.

“Any building or anything like that I’ll get it done professionally. If there is a yard to be done, I am not going to start mixing concrete. When building, hire the experts. Get them in, get them out and have it done right,” he explained.

Specialisation

Historically, the farm would have been a mixed enterprise, but it is now a specialist dairy farm. What really was the turning point for Eamonn was a year spent in New Zealand.

Two big lessons learned were:

- Specialisation is the way to go;

- Let cows out to grass straight after they calve.

These two key lessons Eamonn has carried thoughout the last 25 years.

“I came home and let the cows out and that’s how we are where we are now. I’ve learned a lot in the mean time.”

Eamonn completed a specialised dairy course in the late 1990s when quotas were a huge issue, with the first change coming really in the late 2000s when you could bid without having to take on land.

“The land was a killer before that opened up things,” Eamonn said.

Calves

Cows are monitored and a calving camera is utilised, but for Eamonn, calving runs fairly smoothly with 135 calves so far.

“I have pulled one calf this year; he was backwards. Even the twins calved themselves.”

All births are dairy births. Eamonn uses 100% dairy AI and has no beef stock bull.

“We keep calf rearing as simple as we can; cold milk most of the time with a bottle and teat in the first one hour. Whole milk is fed as it’s just easier. It is more expensive, but I don’t have to mix. Plus, in the beginning, there is lots of waste milk anyway.”

Calves go to ‘Bishopswoods’ at a few weeks old and “are fed milk once-a-day (OAD), with access to the field and a shed.

“They get a kilogram of Calf Starter Mix from Daltons (Kilkenny) once weaned until June. Then, they don’t get anything but grass. However, some of them do get silage. After that, they basically stay there until I sell them.”

Heat detection

Eamonn sells his excess heifers in-calf. This year, he has 89 maiden heifers; they will be AIed to sexed semen and conventional AI for six weeks and then a home-reared stock bull runs for three weeks.

The first 25-30 scanned to calve in the first two weeks of February are kept, calving down to sexed semen (usually the first 60 serves to heifers are sexed straws) and the rest are sold.

In the past, Eamonn has tried tail paint and scratch cards with heifers, but he finds the vasectomised bulls with chin balls excellent. This helps further compact calving and allows a high percentage of heifers to be born right at the start of the season.

Eamonn gets great satisfaction from hearing how well heifers he has sold have performed in other farmer’s herds.

For the dairy cows ,“I swear by tail-paint”. AI on the cows is carried out for 11 or 12 weeks. Last year saw 7% empty.

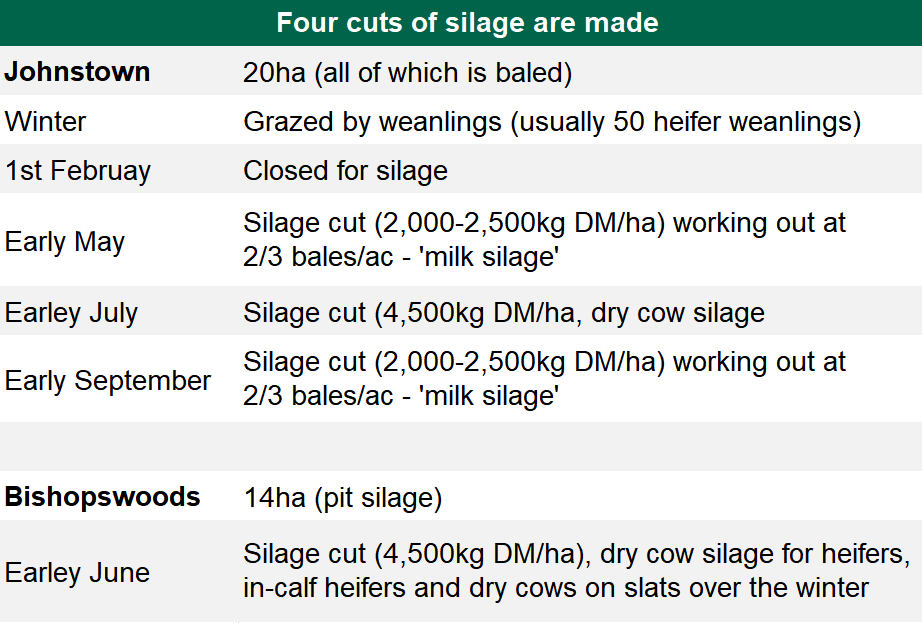

Silage quality

Silage quality is a big part of what Eamonn does with most silage in bale form. The cows get a basic diet of grass, silage and meal (occasionally contracted zero-grazed grass if required), so silage quality is really important.

Bales are stored separately with the ‘milk silage’ a key part of the system. On average, they are 80% DMD plus, 15% protein and 0.94 UFL. This way of doing things is working for Eamonn.

“We’ve found that cow intake increases with these bales and yields are easily maintained,” he added.

Conclusion

Speaking on the future of his herd, Eamonn wants to stay at current numbers while “aiming to improve the herd, in terms of efficiencies and output”.

Having farmed in Tubberboe since 1985, Eamonn has a huge bank of experience, with a good chunk of machinery work outsourced.

There are only three cattle groups for most of the year and other labour reduction actions in place, such as the BattLatch which is saving a huge amount of time.

Eamonn is operating a highly-efficient low-cost system. He does feed what the average farmer is feeding in terms of meal at 800-900kg, but that’s with a stocking rate of 4.0LU/ha on the milking platform and producing a massive 2,000kg of milk solids/ha.

As Eamonn says: “The milking platform is now really humming.”

More information

For more information on services and products provided by Progressive Genetics, just click here

Progressive Genetics is also available on social media: Twitter; Instagram; and Facebook.