Profitable beef production in Ireland is based on the use of high quantities of quality grass to produce beef at a low cost. Central to this, however, is good grazing infrastructure.

Good infrastructure will allow for a longer grazing season and make grazing management easier at peak grass growth periods. It is also a major help at times of challenging weather and ground conditions.

In addition, increasing the quantity of grass utilised on a farm will have positive consequences for the farm’s bottom line. Work carried out by Teagasc shows that improving grass utilisation on a drystock farm is worth an additional €105/ha for every tonne of grass dry matter utilised.

At this week’s BEEF 2018 event in Teagasc Grange, Co. Meath, farmers were presented with a number of grazing infrastructure options.

Paddock size and shape

When it comes to implementing a paddock grazing system, one of the most important aspects to get right is paddock size and shape.

Ideally, farmers should have seven or eight paddocks for each grazing group. This allows the ‘grow in three weeks, graze in three days’ mantra to be practiced.

Moving to paddock design, a 2:1 ratio should be targeted. This means that paddocks should be twice as long as they are wide.

It must be noted that having wide, shallow paddocks increases the likelihood of cattle walking in difficult conditions, thus increasing the chances of poaching.

To access the above mentioned paddocks, roadways may play a crucial role at farm level and they really come into their own during difficult grazing conditions. A number of roadway designs were presented on the day.

At a cost of €25.20/m, the roadway pictured below is ideally suited for heavy soil conditions. The geotextile layer, which lays beneath the road’s surface, acts as a damp-proof layer.

The total depth of the roadway is 11in; this includes a 6in layer of 3in down trunking below the topsoil’s surface, a further 2in layer of the same material above the top soil and 3in of surface blinding material.

The second roadway on show costs €17.50/m to complete. Like the previous example, 6in of soil was removed prior to construction. This time, however, a 6in layer of 4in down trunking was installed below the ground’s surface, while a further 2in was allocated above ground level. This roadway was finished with a 3in layer of surface blinding.

Also featuring a geotextile later, the final roadway (pictured below) costs €14.50/m to complete.

To reduce costs, no surface material was removed prior to installing the roadway. It consists of a 5in layer of 3in down trunking and 3in of surface blinding.

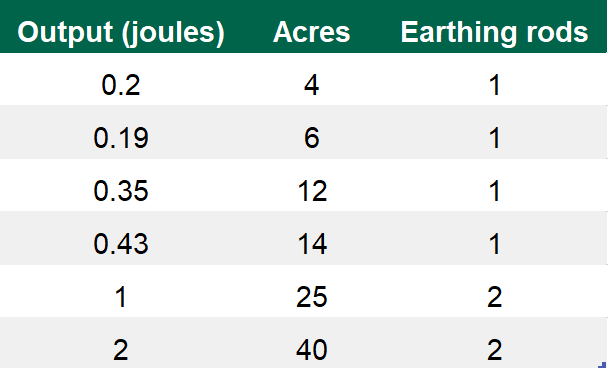

A number of fencing options were also on display on the day and the costs of these varied from €1.50/m all the way up to €6.50/m. When it comes to powering an electric fence, farmers were also advised to select an adequately-powered fencer, which is fit for purpose. Advice was also offered on using the correct size and number of grounding rods.

Battery fencer options:

Another area that’s critical when implementing a paddock grazing system is water.

A good supply of water is vital and that’s dependent on a number of factors, including: water source and pumping capacity; pipe sizes and layout; jet size at ballcock; and trough capacity.

The impact of pipe size was also discussed; the flow area of a 0.75in pipe is two times that of a 0.5in pipe and the flow area of a 1in pipe is four times that of a 0.5in pipe.

Roadway design

Roadway 1

Roadway 2

Roadway 3

Fencing options

Water system