Farming in Longfordpass, Co.Tipperary, Pat Healy runs a 50-cow suckler herd under a split spring and autumn-calving system. The beef farm encompasses 100ac. An out-farm, located 10 miles away, is leased to a dairy farmer.

The farm is home to 25 pedigree Angus cows and 25 commercial cows. Pedigree bulls are sold for breeding and all other offspring are brought to finish. All commercial bulls are slaughtered under 16 months and the heifers are killed at 18-20 months.

Pat also purchases approximately 40 heifers as weanlings; these are slaughtered during the springtime of the year.

“The autumn-calving system is very advantageous for the pedigree herd. It produces an Angus bull at a nice age for the dairy men. When he’s 18-24 months, it coincides with the dairy breeding season,” Pat explained.

As Pat is the only labour unit on the farm, the decision was made to build a new, five-bay slatted and solid floor unit onto an existing slatted shed.

On this, he said: “I was stuck for a shed; I’m not getting any younger and I wanted to make things easier on myself.

“I was okay for slurry storage because I have a high, dry farm and I was also doing some out wintering. But since the new tank was installed, I can store everything and there are no animals outside during the winter months,” he added.

The timescale

Pat outlined the timescale involved to complete the project. The shed was constructed under the Targeted Agricultural Modernisation Scheme (TAMS II) for which he received a 40% grant.

He said: “The shed was in progress for almost two years. You need to have everything perfect with the application. I had to start at the beginning and get in a surveyor and a draftsman.

“All the planning started in March 2016 and the planning permission was granted in May of that year. The planning came through in approximately two months and then we had to wait for a tranche to open up for the TAMS programme.

“We got approval in December 2016 and the first dig commenced in early April 2017. I’m quite happy with the end product and what we achieved here. It’s quite similar to the original unit.”

A simple plan

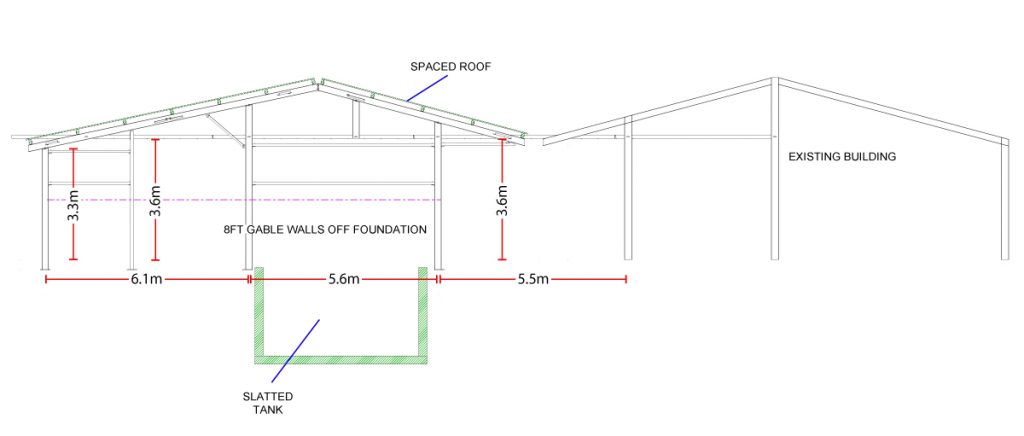

The shed itself is 3.6m high where the new shed and the existing unit meet at the centre feed passage; it is 3.3m high to the eve gutters. The new unit measures 23.8m in length and 17.2m in width. A 78ft long, 16.6ft wide and 8ft deep tank was also installed in the unit.

The centre feed passage is 5.5m wide. The bays at either end of the unit are 4.7m wide, while the middle three bays measure 4.8m in width.

The slatted area is 5.6m wide; calves have access to a solid lie-back area via creep gates. This section is bedded with straw and measures 6.1m in width. Pedestrian gates (man-escape gates) are also located here, which Pat described as being “absolutely brilliant”.

Access is provided through roller doors at either end of the shed. On these, Pat explained: “The roller doors are open 90% of the time. I have the option to close them when we experience extreme weather conditions.

“My autumn calves are allowed free access to grass at the back of the shed during the winter; they can come and go as they please through a door at the back of the lie-back area.

“I think a large lie-back area is needed for the calves. They were too restricted in the other shed; they need room and now they have plenty of it,” he added.

The lie-back area can also be accessed with a tractor to facilitate cleaning out. Pat installed rubber mats on the slats and explained that they provide comfort for his cows.

“I have rubber mats on the slats. They are a great job, but they’re very expensive; I spent €8,000 on these. However, once you provide rubber mats, it’s very seldom you would see cattle lying on the concrete slats,” he explained.

Pillars, clamped to the slats and solid floor, facilitate water troughs and dividing gates. Pat outlined that the pillars work extremely well. The gate also allows the farmer to separate cattle on the slats if the need arises.

Ventilation and lighting

The unit is extremely bright and airy. Pat installed a wind breaker along the length of the structure to improve airflow.

He said: “I liked the idea of the wind breaker. I could sheet it up, but I’d be afraid it would become too still then. I never see cattle cold here and I have had no issues with pneumonia.

“I have not treated one animal in the shed over the whole winter and this has been a tough period. Looking back at November and December, the weather was extremely heavy – that’s the worst weather for animals in a shed. That’s when you need good ventilation,” Pat added.

There is plenty of light in the slatted house. Space sheeting was used on the roof of the shed to allow as much light to enter as possible and also to improve ventilation. Two artificial lights per bay are used at night time.

On this, he added: “If I was to do it all over again, I would probably go with a solid roof. Don’t get me wrong, the airflow is fantastic; but I have the straw bedded lie-back areas and a little drift of rain comes in. The 20mm gap allows rain to enter which dampens the straw; I don’t mind it on the slats.”

Both sheds meet at the centre passage. Thomas Gleeson from Gleeson Steel and Engineering outlined how the two units were grafted together.

“What Pat wanted to do here was to graft the two sheds together and have a valley gutter between them. This would work fine; however, we decided to go with two individual gutters instead and place a crown on top. It works very well,” Thomas explained.

The cost

The shed was designed, supplied and built by Gleeson Steel and Engineering. The fit-out – including the hanging of the feed barriers and gates – was also carried out by the Tipperary-based company.

The total approximate cost of the build was €96,000 (including VAT). This also includes the cost of the rubber mats (€8,000). The TAMS grant amounted to €28,000. However, additional auxiliary concrete and walls are excluded from this price.

On the TAMS grant, Pat said: “It’s great to get it. There’s a lot to it, but it’s definitely worth getting it. The only thing was that it didn’t cover the rubber mats and the auxiliary concrete outside the shed.”

The Angus breeder outlined his future and gave his opinion on the future of suckler farming, adding: “I have a lot of my farming done; what numbers I have at present, I’m happy with. I’m going to keep going the way I’m going.

He continued: “Sucklers can be attractive if you can keep your costs down and produce good pedigree and commercial stock. There can be a decent cut out of it; but keeping the stocking rate right is essential.

“It’s not like dairy farming. You can’t increase output and produce more overnight and have more money out of it. I can only get so much for a pedigree bull. So, the only way I can make more is by keeping my costs down.

“I enjoy farming even more now. A good facility helps and makes the job a lot easier,” he concluded.